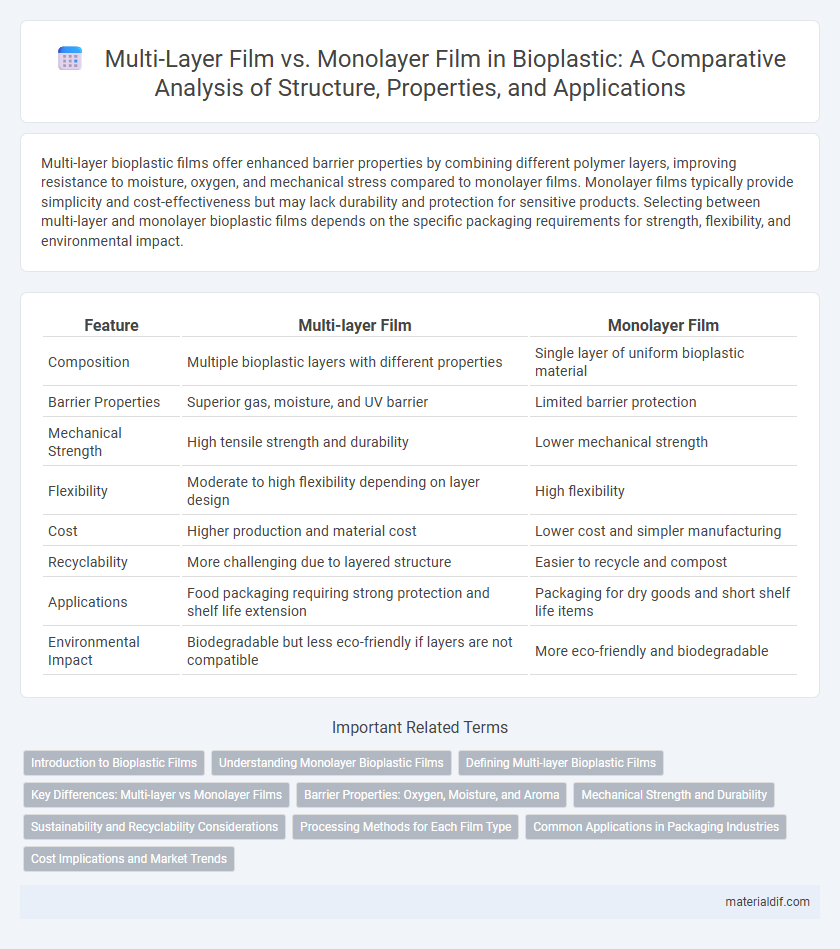

Multi-layer bioplastic films offer enhanced barrier properties by combining different polymer layers, improving resistance to moisture, oxygen, and mechanical stress compared to monolayer films. Monolayer films typically provide simplicity and cost-effectiveness but may lack durability and protection for sensitive products. Selecting between multi-layer and monolayer bioplastic films depends on the specific packaging requirements for strength, flexibility, and environmental impact.

Table of Comparison

| Feature | Multi-layer Film | Monolayer Film |

|---|---|---|

| Composition | Multiple bioplastic layers with different properties | Single layer of uniform bioplastic material |

| Barrier Properties | Superior gas, moisture, and UV barrier | Limited barrier protection |

| Mechanical Strength | High tensile strength and durability | Lower mechanical strength |

| Flexibility | Moderate to high flexibility depending on layer design | High flexibility |

| Cost | Higher production and material cost | Lower cost and simpler manufacturing |

| Recyclability | More challenging due to layered structure | Easier to recycle and compost |

| Applications | Food packaging requiring strong protection and shelf life extension | Packaging for dry goods and short shelf life items |

| Environmental Impact | Biodegradable but less eco-friendly if layers are not compatible | More eco-friendly and biodegradable |

Introduction to Bioplastic Films

Bioplastic films offer sustainable alternatives to traditional plastic films, with multi-layer films providing enhanced barrier properties by combining different biopolymer layers to protect against moisture, oxygen, and UV light. Monolayer bioplastic films consist of a single polymer layer, offering simplicity and easier recyclability but often with limited functional performance compared to multi-layer structures. The choice between multi-layer and monolayer bioplastic films depends on the specific packaging requirements, balancing durability, environmental impact, and cost-effectiveness.

Understanding Monolayer Bioplastic Films

Monolayer bioplastic films consist of a single homogeneous layer made from biodegradable polymers such as PLA or PHA, offering simplicity in manufacturing and recycling. These films provide essential barrier properties against moisture and gases but may lack the enhanced mechanical strength and flexibility found in multi-layer films. Understanding the intrinsic properties of monolayer bioplastic films is crucial for optimizing their use in packaging applications where environmental sustainability and efficient biodegradability are priorities.

Defining Multi-layer Bioplastic Films

Multi-layer bioplastic films consist of several polymer layers combined to enhance barrier properties such as moisture, oxygen, and UV resistance, crucial for food packaging and preservation. Each layer in a multi-layer film serves a specific function, enabling the customization of mechanical strength, flexibility, and biodegradability that monolayer films cannot achieve alone. This complex structure improves the overall performance and sustainability of bioplastics compared to the simpler monolayer films.

Key Differences: Multi-layer vs Monolayer Films

Multi-layer films consist of multiple layers of bioplastic materials engineered to enhance barrier properties against moisture, oxygen, and UV light, offering superior durability and performance compared to monolayer films. Monolayer films are composed of a single bioplastic layer, making them simpler and more cost-effective but with limited protection and mechanical strength. Key differences include the multi-layer films' advanced functionality tailored for complex packaging needs, whereas monolayer films suit applications requiring basic biodegradability and flexibility.

Barrier Properties: Oxygen, Moisture, and Aroma

Multi-layer bioplastic films provide superior barrier properties against oxygen, moisture, and aroma compared to monolayer films due to their composite structure combining different polymer layers. Each layer in a multi-layer film is engineered to target specific permeability challenges, resulting in enhanced preservation and extended shelf life for packaged goods. Monolayer films generally exhibit higher gas and vapor transmission rates, making them less effective for applications requiring stringent barrier performance.

Mechanical Strength and Durability

Multi-layer films exhibit superior mechanical strength and enhanced durability compared to monolayer films due to their composite structure that combines different materials, optimizing barrier properties and resistance to puncture. The layered configuration in multi-layer bioplastic films provides improved tensile strength and impact resistance, making them ideal for packaging applications requiring extended shelf life. Monolayer bioplastic films, while simpler and more cost-effective, generally offer lower mechanical robustness and reduced resistance to environmental stressors.

Sustainability and Recyclability Considerations

Multi-layer films offer enhanced barrier properties for food preservation but pose significant challenges in recyclability due to the difficulty in separating different polymer layers, often leading to landfill disposal or incineration. In contrast, monolayer bioplastic films are more sustainable and easier to recycle because they consist of a single polymer type, promoting circularity and reducing environmental impact. Choosing monolayer films supports biodegradable waste management systems and aligns with eco-friendly packaging initiatives aiming to minimize plastic pollution.

Processing Methods for Each Film Type

Multi-layer films are typically produced using co-extrusion or lamination techniques, allowing precise control over the combination of diverse bioplastic materials to enhance barrier properties and mechanical strength. Monolayer films are usually processed via single extrusion or blown film extrusion, offering simplicity and cost-effectiveness but with limited functional performance compared to multi-layer structures. Advanced processing methods such as reactive extrusion or surface coating can further modify film properties to meet specific application requirements in bioplastic packaging.

Common Applications in Packaging Industries

Multi-layer films in packaging industries offer enhanced barrier properties, making them ideal for food products requiring extended shelf life, such as frozen foods and snacks. Monolayer films are commonly used for simpler applications like grocery bags and produce wraps due to their cost-effectiveness and ease of recycling. The choice between multi-layer and monolayer films depends on the balance between protection needs and sustainability goals in packaging design.

Cost Implications and Market Trends

Multi-layer bioplastic films offer superior barrier properties and durability, which increases production costs compared to more affordable monolayer films favored in cost-sensitive applications. Market trends show rising demand for multi-layer films in packaging sectors requiring extended shelf life, driving innovation but also higher price points. Cost-efficient monolayer films remain dominant in markets prioritizing biodegradability and recyclability despite their limited functional performance.

Multi-layer Film vs Monolayer Film Infographic

materialdif.com

materialdif.com