Bioresin, derived from renewable biomass sources, offers a sustainable alternative to petroleum resin by reducing carbon emissions and dependence on fossil fuels. Unlike petroleum resin, which is produced from non-renewable crude oil, bioresin is biodegradable and supports circular economy practices. The growing demand for eco-friendly materials drives innovation in bioresin formulations, enhancing their performance in packaging, automotive, and consumer goods industries.

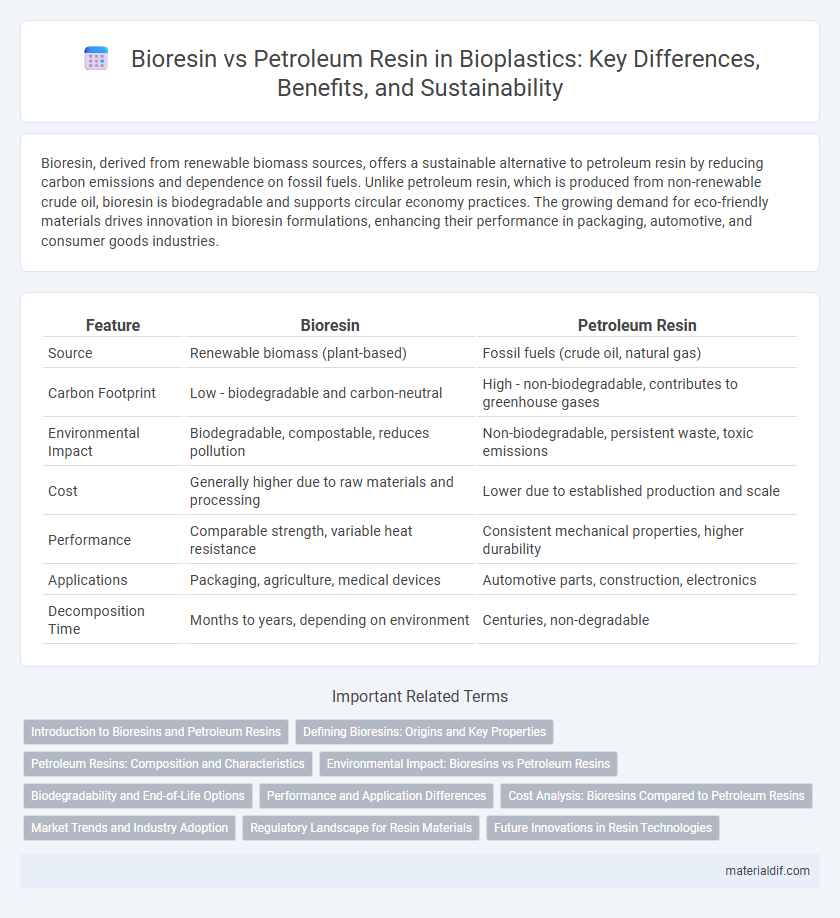

Table of Comparison

| Feature | Bioresin | Petroleum Resin |

|---|---|---|

| Source | Renewable biomass (plant-based) | Fossil fuels (crude oil, natural gas) |

| Carbon Footprint | Low - biodegradable and carbon-neutral | High - non-biodegradable, contributes to greenhouse gases |

| Environmental Impact | Biodegradable, compostable, reduces pollution | Non-biodegradable, persistent waste, toxic emissions |

| Cost | Generally higher due to raw materials and processing | Lower due to established production and scale |

| Performance | Comparable strength, variable heat resistance | Consistent mechanical properties, higher durability |

| Applications | Packaging, agriculture, medical devices | Automotive parts, construction, electronics |

| Decomposition Time | Months to years, depending on environment | Centuries, non-degradable |

Introduction to Bioresins and Petroleum Resins

Bioresins are derived from renewable biomass sources such as corn, sugarcane, and cellulose, offering a sustainable alternative to petroleum-based resins which are produced from fossil fuels like crude oil and natural gas. Bioresins exhibit biodegradability and reduced carbon footprint, making them favorable in applications requiring environmental sustainability. Petroleum resins provide robust mechanical properties and chemical resistance, widely used in adhesives, coatings, and plastics but contribute to environmental pollution due to their non-renewable origin.

Defining Bioresins: Origins and Key Properties

Bioresins are derived from renewable biological sources such as plants, algae, and microorganisms, distinguishing them from petroleum resins that originate from fossil fuels. These biopolymeric materials exhibit properties like biodegradability, lower carbon footprint, and potential for reduced environmental impact compared to conventional petroleum-based resins. Key characteristics of bioresins include their chemical structure variability influenced by biomass feedstock and ability to be engineered for specific applications in packaging, agriculture, and biomedical fields.

Petroleum Resins: Composition and Characteristics

Petroleum resins are synthetic polymers derived primarily from the polymerization of petrochemical feedstocks such as C5 and C9 hydrocarbons, including isoprene, piperylene, and styrene monomers. These resins exhibit excellent adhesion, flexibility, and compatibility with various materials, making them suitable for adhesives, coatings, and rubber compounding. Their hydrophobic nature and thermal stability provide superior performance in harsh environmental conditions compared to bioresins.

Environmental Impact: Bioresins vs Petroleum Resins

Bioresins, derived from renewable biomass sources such as corn, sugarcane, and cellulose, significantly reduce carbon emissions compared to petroleum resins, which are fossil fuel-based and contribute heavily to greenhouse gas emissions. The biodegradability of bioresins minimizes long-term environmental pollution, unlike petroleum resins that persist in ecosystems and contribute to microplastic contamination. Lifecycle analyses indicate bioresins have a smaller ecological footprint, supporting sustainable production and waste management practices.

Biodegradability and End-of-Life Options

Bioresin, derived from renewable biomass sources such as corn starch or sugarcane, offers superior biodegradability compared to petroleum resin, breaking down more efficiently in composting and natural environments. This bioplastic supports end-of-life options like industrial composting and anaerobic digestion, reducing landfill accumulation and environmental impact. In contrast, petroleum resin, sourced from fossil fuels, resists biodegradation, leading to persistent waste and limited recycling pathways.

Performance and Application Differences

Bioresin, derived from renewable biomass such as corn or sugarcane, offers superior biodegradability and lower carbon footprints compared to petroleum resin, which is synthesized from fossil fuels and often exhibits greater chemical resistance and thermal stability. In performance terms, bioresins typically excel in compostability and environmental sustainability, making them ideal for packaging, agricultural films, and disposable items, whereas petroleum resins are favored in automotive parts, electrical components, and long-lasting consumer goods due to their durability and heat resistance. The application differences hinge on lifecycle impact, with bioresins targeting eco-friendly markets and petroleum resins dominating industries requiring high-performance material longevity.

Cost Analysis: Bioresins Compared to Petroleum Resins

Bioresins generally exhibit higher production costs compared to petroleum resins due to the reliance on renewable raw materials and less established manufacturing processes. Despite the premium pricing, bioresins offer long-term economic advantages through sustainability incentives and reduced environmental compliance expenses. Market demand shifts and technological advancements are driving cost convergence between bioresins and traditional petroleum-based resins.

Market Trends and Industry Adoption

Bioresin markets have experienced rapid growth, driven by increasing consumer demand for sustainable materials and stricter environmental regulations limiting petroleum resin use. Major industries such as packaging, automotive, and consumer goods are increasingly adopting bioresins to reduce carbon footprints and enhance biodegradability. Market forecasts predict bioresin adoption will surpass petroleum resins by 2030, fueled by innovations in feedstock sources and enhanced performance characteristics.

Regulatory Landscape for Resin Materials

Bioresin materials are increasingly favored under evolving global regulations aimed at reducing carbon emissions and promoting sustainable sourcing, including the EU's REACH regulations and the U.S. Toxic Substances Control Act (TSCA) updates. Petroleum resins face stricter scrutiny due to volatile organic compound (VOC) emissions and dependency on fossil fuels, driving limitations and potential phase-outs in certain markets. Compliance with these regulatory frameworks is critical for manufacturers to ensure market access and align with environmental targets promoting bio-based and biodegradable alternatives.

Future Innovations in Resin Technologies

Bioresin developments are rapidly advancing with innovations centered on enhancing biodegradability and reducing carbon footprints compared to traditional petroleum resins derived from fossil fuels. Emerging technologies exploit renewable feedstocks like plant-based sugars and algae, enabling scalable production of high-performance bio-based polymers with improved mechanical properties. Future innovations emphasize integrating nanotechnology and enzyme catalysis to optimize resin synthesis, supporting sustainable packaging and automotive applications.

Bioresin vs Petroleum resin Infographic

materialdif.com

materialdif.com