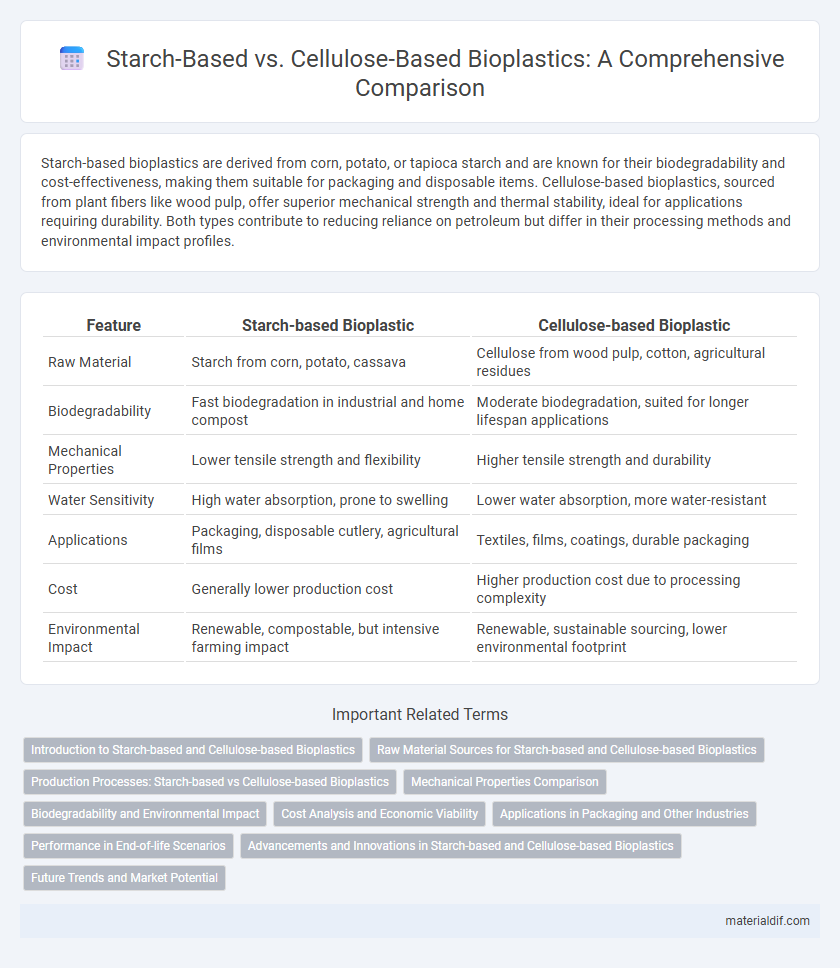

Starch-based bioplastics are derived from corn, potato, or tapioca starch and are known for their biodegradability and cost-effectiveness, making them suitable for packaging and disposable items. Cellulose-based bioplastics, sourced from plant fibers like wood pulp, offer superior mechanical strength and thermal stability, ideal for applications requiring durability. Both types contribute to reducing reliance on petroleum but differ in their processing methods and environmental impact profiles.

Table of Comparison

| Feature | Starch-based Bioplastic | Cellulose-based Bioplastic |

|---|---|---|

| Raw Material | Starch from corn, potato, cassava | Cellulose from wood pulp, cotton, agricultural residues |

| Biodegradability | Fast biodegradation in industrial and home compost | Moderate biodegradation, suited for longer lifespan applications |

| Mechanical Properties | Lower tensile strength and flexibility | Higher tensile strength and durability |

| Water Sensitivity | High water absorption, prone to swelling | Lower water absorption, more water-resistant |

| Applications | Packaging, disposable cutlery, agricultural films | Textiles, films, coatings, durable packaging |

| Cost | Generally lower production cost | Higher production cost due to processing complexity |

| Environmental Impact | Renewable, compostable, but intensive farming impact | Renewable, sustainable sourcing, lower environmental footprint |

Introduction to Starch-based and Cellulose-based Bioplastics

Starch-based bioplastics are derived from natural starch sources such as corn, potato, and tapioca, offering biodegradability and cost-effectiveness for packaging and agricultural applications. Cellulose-based bioplastics utilize cellulose extracted from wood pulp, cotton, or hemp, providing enhanced mechanical strength and thermal stability compared to starch-based alternatives. Both types contribute to reducing dependence on fossil fuels and lowering greenhouse gas emissions in the plastic industry.

Raw Material Sources for Starch-based and Cellulose-based Bioplastics

Starch-based bioplastics are primarily derived from renewable sources such as corn, potato, and cassava, offering high biodegradability and cost-effective production. Cellulose-based bioplastics utilize raw materials like wood pulp, cotton fibers, and agricultural residues, providing strong mechanical properties and excellent film-forming capabilities. Both sources contribute to sustainable packaging solutions by reducing reliance on fossil fuels and enhancing environmental compatibility.

Production Processes: Starch-based vs Cellulose-based Bioplastics

Starch-based bioplastics are produced primarily through the gelatinization and plasticization of natural starch extracted from crops like corn or potatoes, involving processes such as extrusion or casting to form flexible materials. Cellulose-based bioplastics utilize cellulose fibers from plant cell walls, which undergo chemical treatment like esterification or acetylation to create thermoplastic cellulose esters with enhanced mechanical properties. The production of starch-based bioplastics is generally more energy-efficient but limited in moisture resistance, whereas cellulose-based bioplastics offer superior durability and thermal stability due to their complex polymer modifications.

Mechanical Properties Comparison

Starch-based bioplastics generally exhibit lower tensile strength and flexibility compared to cellulose-based bioplastics, which offer superior mechanical durability and dimensional stability. Cellulose-based materials demonstrate higher Young's modulus and impact resistance, making them more suitable for applications requiring robustness and resistance to deformation. The inherent crystallinity of cellulose contributes to enhanced mechanical properties, whereas starch's amorphous structure results in quicker degradation and lower mechanical integrity.

Biodegradability and Environmental Impact

Starch-based bioplastics exhibit rapid biodegradability due to their natural polysaccharide structure, breaking down efficiently in soil and compost environments within weeks. Cellulose-based bioplastics also demonstrate excellent biodegradability but tend to persist slightly longer, offering enhanced mechanical strength and moisture resistance, which can influence their degradation timeline. Both types significantly reduce environmental impact compared to petroleum-based plastics by minimizing greenhouse gas emissions and decreasing reliance on fossil fuels, with starch-based variants often favored for single-use applications due to faster decomposition.

Cost Analysis and Economic Viability

Starch-based bioplastics generally offer lower production costs due to abundant raw materials like corn and potato starch, making them economically viable for large-scale applications such as packaging. In contrast, cellulose-based bioplastics, derived from wood pulp or agricultural residues, involve more complex extraction and processing techniques, leading to higher manufacturing expenses and limited market penetration. Evaluations indicate that while starch-based options dominate cost efficiency, cellulose-based bioplastics provide advantages in durability and biodegradability that may justify their premium price in specialized sectors.

Applications in Packaging and Other Industries

Starch-based bioplastics excel in food packaging due to their biodegradability and cost-effectiveness, making them ideal for disposable trays, bags, and films. Cellulose-based bioplastics offer superior mechanical strength and barrier properties, supporting applications in durable packaging, pharmaceuticals, and textiles. Both materials contribute to eco-friendly solutions by reducing reliance on fossil fuels and enhancing compostability across diverse industries.

Performance in End-of-life Scenarios

Starch-based bioplastics typically exhibit higher biodegradability in composting environments, breaking down rapidly under industrial composting conditions due to their natural polysaccharide structure. Cellulose-based bioplastics demonstrate superior mechanical strength and durability but often require more specific enzymatic or microbial activity for efficient degradation in soil or marine settings. Performance at end-of-life varies significantly, with starch-based options favoring quick compostability and cellulose-based materials offering longer-lasting applications before biodegradation.

Advancements and Innovations in Starch-based and Cellulose-based Bioplastics

Starch-based bioplastics have seen significant advancements through the incorporation of nanotechnology and plasticizers, enhancing their mechanical strength and biodegradability for packaging and agricultural applications. Innovations in cellulose-based bioplastics focus on improving thermal stability and water resistance by utilizing cellulose nanocrystals and chemical modifications, expanding their use in medical devices and flexible electronics. Both starch-based and cellulose-based bioplastics benefit from research into enzymatic treatments and bio-composites, which optimize their environmental performance and functional properties.

Future Trends and Market Potential

Starch-based bioplastics exhibit strong growth potential due to their cost-effectiveness and biodegradability, driving demand in packaging and agricultural sectors. Cellulose-based bioplastics offer superior mechanical properties and eco-friendly sourcing, attracting innovation in medical and automotive industries. Future market trends emphasize hybrid materials combining starch and cellulose to enhance performance while maintaining sustainability, expanding their global commercial viability.

Starch-based vs Cellulose-based Infographic

materialdif.com

materialdif.com