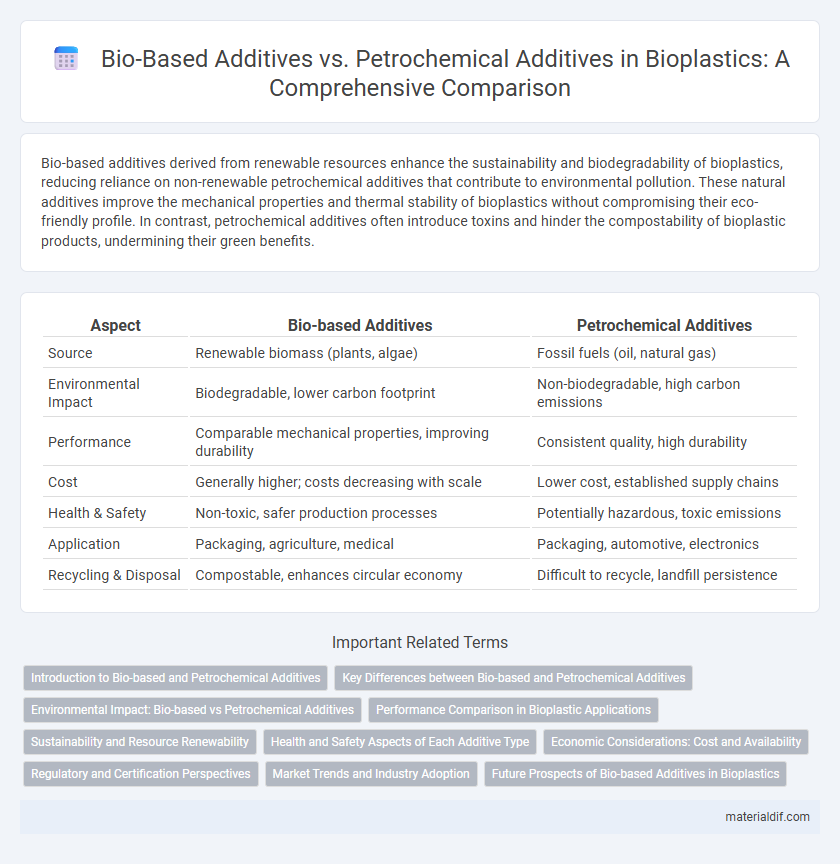

Bio-based additives derived from renewable resources enhance the sustainability and biodegradability of bioplastics, reducing reliance on non-renewable petrochemical additives that contribute to environmental pollution. These natural additives improve the mechanical properties and thermal stability of bioplastics without compromising their eco-friendly profile. In contrast, petrochemical additives often introduce toxins and hinder the compostability of bioplastic products, undermining their green benefits.

Table of Comparison

| Aspect | Bio-based Additives | Petrochemical Additives |

|---|---|---|

| Source | Renewable biomass (plants, algae) | Fossil fuels (oil, natural gas) |

| Environmental Impact | Biodegradable, lower carbon footprint | Non-biodegradable, high carbon emissions |

| Performance | Comparable mechanical properties, improving durability | Consistent quality, high durability |

| Cost | Generally higher; costs decreasing with scale | Lower cost, established supply chains |

| Health & Safety | Non-toxic, safer production processes | Potentially hazardous, toxic emissions |

| Application | Packaging, agriculture, medical | Packaging, automotive, electronics |

| Recycling & Disposal | Compostable, enhances circular economy | Difficult to recycle, landfill persistence |

Introduction to Bio-based and Petrochemical Additives

Bio-based additives in bioplastics derive from renewable resources such as plants, enhancing biodegradability and reducing carbon footprint compared to petrochemical additives sourced from fossil fuels. These bio-based additives improve material properties like flexibility, UV stability, and processing efficiency while promoting sustainability in plastic production. In contrast, petrochemical additives often offer cost-effectiveness and established performance but contribute to environmental pollution and resource depletion.

Key Differences between Bio-based and Petrochemical Additives

Bio-based additives derive from renewable resources such as plants, contributing to enhanced biodegradability and reduced carbon footprint of bioplastics, while petrochemical additives originate from fossil fuels, often resulting in higher environmental impact. Bio-based additives typically exhibit better compatibility with biopolymer matrices, improving mechanical properties and processability without compromising sustainability. Petrochemical additives, despite their widespread availability and cost-effectiveness, pose challenges in biodegradability and may release toxic substances during degradation, highlighting a critical difference in environmental performance.

Environmental Impact: Bio-based vs Petrochemical Additives

Bio-based additives derived from renewable resources significantly reduce carbon footprint and biodegrade more easily compared to petrochemical additives, which rely on finite fossil fuels and contribute to long-term environmental pollution. Studies show bio-based additives improve the sustainability of bioplastic products by enhancing compostability and reducing toxic residue in soil and water. Petrochemical additives often release harmful volatile organic compounds (VOCs) during production and disposal, increasing ecological toxicity and greenhouse gas emissions.

Performance Comparison in Bioplastic Applications

Bio-based additives in bioplastics offer enhanced biodegradability and reduced environmental impact compared to petrochemical additives, which often provide superior mechanical strength and thermal stability. Performance in applications such as packaging and automotive parts varies, with bio-based additives excelling in flexibility and compostability but sometimes compromising durability and heat resistance. Selecting additives depends on balancing eco-friendly attributes with the required performance metrics for specific bioplastic uses.

Sustainability and Resource Renewability

Bio-based additives in bioplastics offer enhanced sustainability by utilizing renewable resources derived from biomass, reducing dependence on finite fossil fuels and lowering the overall carbon footprint. Petrochemical additives rely on non-renewable petroleum sources, contributing to environmental degradation and resource depletion. Incorporating bio-based additives promotes circular economy principles by enabling biodegradability and minimizing ecological impact throughout the plastic lifecycle.

Health and Safety Aspects of Each Additive Type

Bio-based additives in bioplastics offer reduced toxicity and lower environmental impact compared to petrochemical additives, which often contain hazardous substances linked to health risks such as respiratory issues and skin irritation. Health and safety assessments highlight that bio-based additives promote safer production and disposal processes by minimizing exposure to harmful chemicals. The use of renewable, non-toxic bio-based additives aligns with stricter regulatory standards and enhances worker safety across bioplastic manufacturing industries.

Economic Considerations: Cost and Availability

Bio-based additives often incur higher production costs compared to petrochemical additives due to the complexity of sourcing renewable raw materials and smaller-scale manufacturing processes. Petrochemical additives benefit from established supply chains and economies of scale, resulting in greater availability and lower market prices. Shifting to bio-based additives may require initial investments but can leverage long-term sustainability incentives and fluctuating fossil fuel prices to achieve competitive economic advantages.

Regulatory and Certification Perspectives

Bio-based additives in bioplastics benefit from increasing regulatory support and certifications such as USDA BioPreferred and EN 13432, emphasizing sustainability and reduced environmental impact. Petrochemical additives often face stricter regulations due to toxicity concerns and limited biodegradability, impacting their approval and market acceptance. Certification standards prioritize bio-based content and compostability, driving demand for additives derived from renewable resources.

Market Trends and Industry Adoption

Bio-based additives are driving significant growth in the bioplastic market due to increasing environmental regulations and consumer demand for sustainable products. The industry is shifting from petrochemical additives, which account for a large share of traditional plastics, toward renewable, non-toxic alternatives to improve biodegradability and reduce carbon footprint. Market adoption is accelerated by rising investments in biopolymer R&D and government incentives promoting green materials in packaging, automotive, and consumer goods sectors.

Future Prospects of Bio-based Additives in Bioplastics

Bio-based additives in bioplastics exhibit enhanced biodegradability and reduced environmental impact compared to petrochemical additives, driving a shift toward sustainable material innovation. Advances in biotechnology and green chemistry are expanding the range of functional bio-based additives, improving mechanical properties and thermal stability of bioplastics. Market trends indicate increasing regulatory support and consumer demand, positioning bio-based additives as pivotal in reducing carbon footprint and fostering circular economy models in plastic manufacturing.

Bio-based additives vs Petrochemical additives Infographic

materialdif.com

materialdif.com