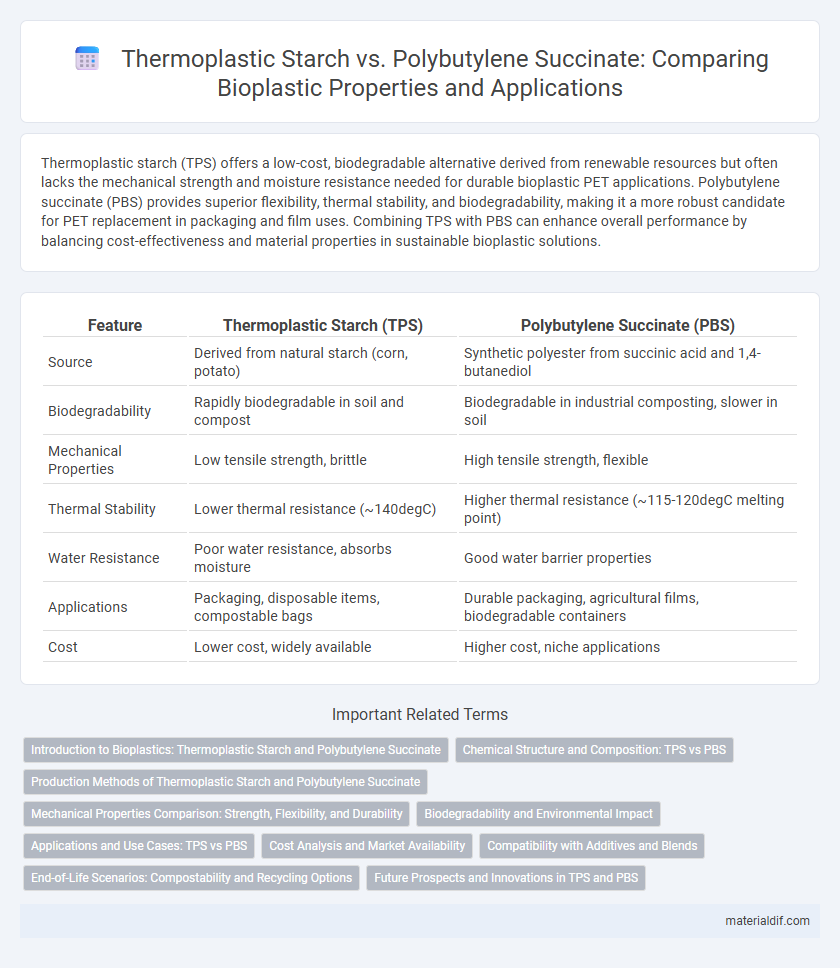

Thermoplastic starch (TPS) offers a low-cost, biodegradable alternative derived from renewable resources but often lacks the mechanical strength and moisture resistance needed for durable bioplastic PET applications. Polybutylene succinate (PBS) provides superior flexibility, thermal stability, and biodegradability, making it a more robust candidate for PET replacement in packaging and film uses. Combining TPS with PBS can enhance overall performance by balancing cost-effectiveness and material properties in sustainable bioplastic solutions.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Polybutylene Succinate (PBS) |

|---|---|---|

| Source | Derived from natural starch (corn, potato) | Synthetic polyester from succinic acid and 1,4-butanediol |

| Biodegradability | Rapidly biodegradable in soil and compost | Biodegradable in industrial composting, slower in soil |

| Mechanical Properties | Low tensile strength, brittle | High tensile strength, flexible |

| Thermal Stability | Lower thermal resistance (~140degC) | Higher thermal resistance (~115-120degC melting point) |

| Water Resistance | Poor water resistance, absorbs moisture | Good water barrier properties |

| Applications | Packaging, disposable items, compostable bags | Durable packaging, agricultural films, biodegradable containers |

| Cost | Lower cost, widely available | Higher cost, niche applications |

Introduction to Bioplastics: Thermoplastic Starch and Polybutylene Succinate

Thermoplastic starch (TPS) is a biodegradable bioplastic derived from native starch modified by plasticizers to produce flexible materials with applications in packaging and disposable items. Polybutylene succinate (PBS) is a synthetic biodegradable polymer produced from succinic acid and 1,4-butanediol, offering superior mechanical properties and thermal stability compared to TPS. Both TPS and PBS contribute to sustainable materials development by reducing reliance on fossil fuels and enhancing compostability in bio-based product solutions.

Chemical Structure and Composition: TPS vs PBS

Thermoplastic starch (TPS) is primarily composed of amylose and amylopectin polymers derived from natural starch, chemically modified through plasticization with glycerol or water to enhance flexibility. Polybutylene succinate (PBS) is a synthetic aliphatic polyester synthesized via polycondensation of 1,4-butanediol and succinic acid, exhibiting a semicrystalline structure with ester linkages that confer biodegradability and mechanical strength. The chemical composition of TPS is based on polysaccharide chains, while PBS consists of saturated ester bonds, resulting in distinct thermal and mechanical properties suitable for different bioplastic applications.

Production Methods of Thermoplastic Starch and Polybutylene Succinate

Thermoplastic starch (TPS) is produced by gelatinizing natural starch in the presence of plasticizers such as glycerol or sorbitol, using processes like extrusion or molding to achieve a thermoplastic state. Polybutylene succinate (PBS) is synthesized through polycondensation of succinic acid and 1,4-butanediol, often utilizing bio-based feedstocks, and processed via conventional polymer techniques including extrusion and injection molding. The distinct production pathways impact their biodegradability, mechanical properties, and application scope in sustainable packaging and agricultural films.

Mechanical Properties Comparison: Strength, Flexibility, and Durability

Thermoplastic starch (TPS) exhibits moderate tensile strength and high flexibility but has lower durability due to its sensitivity to moisture and temperature fluctuations. Polybutylene succinate (PBS) demonstrates superior mechanical strength, enhanced flexibility, and excellent durability, making it more suitable for long-term applications and environments with varying conditions. The distinct difference in polymer structure contributes to PBS's greater resilience and impact resistance compared to the biodegradable yet less robust TPS.

Biodegradability and Environmental Impact

Thermoplastic starch (TPS) exhibits rapid biodegradability due to its natural polysaccharide structure, breaking down efficiently in soil and compost environments within weeks to months. Polybutylene succinate (PBS), a synthetic aliphatic polyester derived from renewable resources, offers slower but more controlled biodegradation, maintaining mechanical properties longer in industrial composting conditions. TPS has a lower environmental impact during production due to its starch base but can suffer from moisture sensitivity, while PBS balances biodegradability with durability, contributing to reduced plastic pollution and greenhouse gas emissions when end-of-life conditions are optimized.

Applications and Use Cases: TPS vs PBS

Thermoplastic starch (TPS) is widely used in packaging, agricultural films, and biodegradable bags due to its low cost and compostability, making it ideal for single-use applications. Polybutylene succinate (PBS) offers higher mechanical strength and thermal stability, suited for durable goods, food containers, and medical devices where extended use and structural integrity are required. The choice between TPS and PBS depends on application-specific demands for biodegradability, robustness, and environmental impact.

Cost Analysis and Market Availability

Thermoplastic starch (TPS) is cost-effective due to its low raw material price derived from abundant starch sources, making it highly competitive in price-sensitive markets, whereas Polybutylene succinate (PBS) incurs higher production costs linked to petrochemical feedstocks and more complex synthesis processes. TPS enjoys widespread market availability, especially in packaging and disposable products, driven by its biodegradability and renewable origin, while PBS, though less prevalent, is gaining traction in specialty applications requiring better mechanical properties and thermal resistance. Market trends indicate a growing demand for PBS in high-performance bioplastics, but TPS remains dominant in bulk, low-cost applications due to its economic advantage.

Compatibility with Additives and Blends

Thermoplastic starch (TPS) exhibits excellent compatibility with natural fillers and plasticizers, enhancing biodegradability and flexibility in blends. Polybutylene succinate (PBS) shows strong adaptability with synthetic additives and polymer blends, improving mechanical properties and thermal stability. Both materials offer versatile blending options, but PBS provides broader compatibility with industrial-grade additives for advanced applications.

End-of-Life Scenarios: Compostability and Recycling Options

Thermoplastic starch (TPS) offers excellent compostability in industrial and home composting settings due to its natural biodegradability, breaking down into water, carbon dioxide, and biomass within months. Polybutylene succinate (PBS) is also compostable under industrial conditions but has greater mechanical strength and thermal stability, making it more suitable for recycling through conventional plastic streams when separate collection systems exist. The choice between TPS and PBS in end-of-life scenarios depends on local waste management infrastructure, with TPS favored for composting and PBS providing flexible options for both composting and mechanical recycling.

Future Prospects and Innovations in TPS and PBS

Thermoplastic starch (TPS) and polybutylene succinate (PBS) are poised for significant advancements driven by sustainable packaging demands and biodegradable material innovation. Future research emphasizes enhancing TPS's mechanical properties and thermal stability through nano-reinforcements and blending techniques, while PBS development focuses on improving biodegradability rates and cost-effectiveness via bio-based monomers and copolymerization. Innovations in both bioplastics aim to optimize performance for diverse applications in agriculture, packaging, and medical fields, aligning with circular economy principles and reducing reliance on fossil fuels.

Thermoplastic starch vs Polybutylene succinate Infographic

materialdif.com

materialdif.com