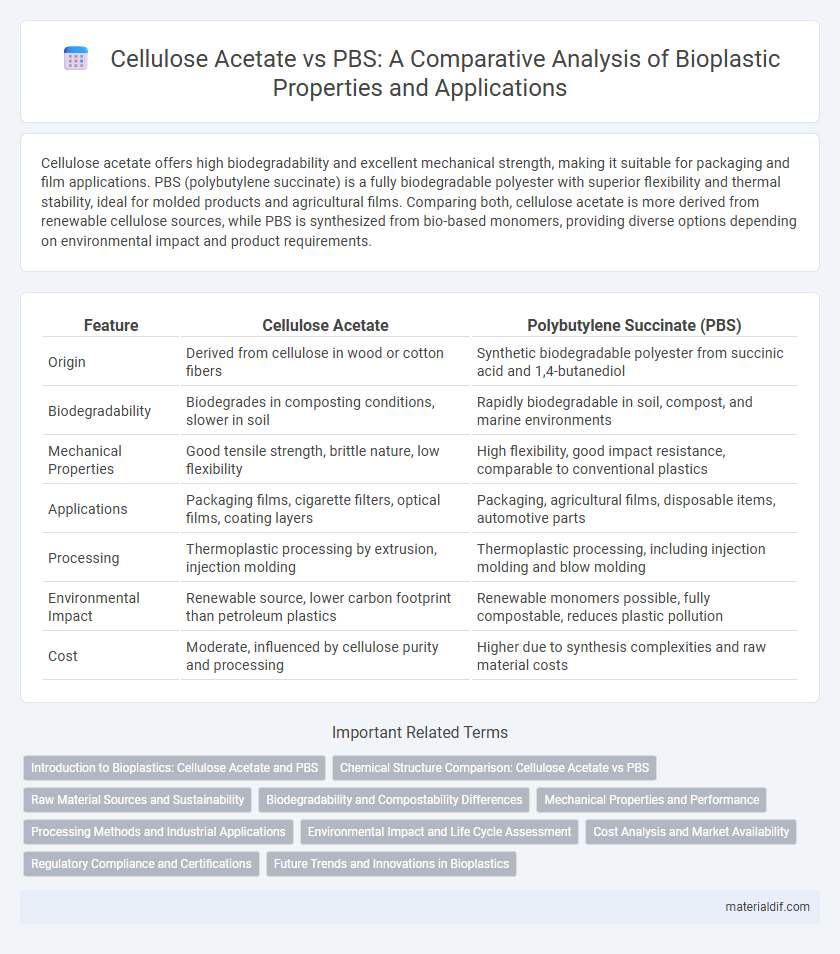

Cellulose acetate offers high biodegradability and excellent mechanical strength, making it suitable for packaging and film applications. PBS (polybutylene succinate) is a fully biodegradable polyester with superior flexibility and thermal stability, ideal for molded products and agricultural films. Comparing both, cellulose acetate is more derived from renewable cellulose sources, while PBS is synthesized from bio-based monomers, providing diverse options depending on environmental impact and product requirements.

Table of Comparison

| Feature | Cellulose Acetate | Polybutylene Succinate (PBS) |

|---|---|---|

| Origin | Derived from cellulose in wood or cotton fibers | Synthetic biodegradable polyester from succinic acid and 1,4-butanediol |

| Biodegradability | Biodegrades in composting conditions, slower in soil | Rapidly biodegradable in soil, compost, and marine environments |

| Mechanical Properties | Good tensile strength, brittle nature, low flexibility | High flexibility, good impact resistance, comparable to conventional plastics |

| Applications | Packaging films, cigarette filters, optical films, coating layers | Packaging, agricultural films, disposable items, automotive parts |

| Processing | Thermoplastic processing by extrusion, injection molding | Thermoplastic processing, including injection molding and blow molding |

| Environmental Impact | Renewable source, lower carbon footprint than petroleum plastics | Renewable monomers possible, fully compostable, reduces plastic pollution |

| Cost | Moderate, influenced by cellulose purity and processing | Higher due to synthesis complexities and raw material costs |

Introduction to Bioplastics: Cellulose Acetate and PBS

Cellulose acetate is a biodegradable bioplastic derived from cellulose, widely used for films, coatings, and fibers due to its excellent transparency and mechanical strength. Polybutylene succinate (PBS) is a biodegradable aliphatic polyester produced from renewable resources, known for its high thermal stability and flexibility, making it suitable for packaging and agricultural applications. Both cellulose acetate and PBS contribute to sustainable materials by reducing dependence on fossil fuels and enhancing biodegradability in various industrial uses.

Chemical Structure Comparison: Cellulose Acetate vs PBS

Cellulose Acetate features a semi-synthetic polymer structure derived from cellulose with acetyl groups replacing some hydroxyl groups, resulting in a thermoplastic with moderate crystallinity. Polybutylene Succinate (PBS) is a fully synthetic aliphatic polyester composed of butylene glycol and succinic acid, characterized by its biodegradable ester linkages and high crystallinity. The chemical structure of Cellulose Acetate provides rigidity due to its polysaccharide backbone, whereas PBS offers flexibility and biodegradability through its ester bonds and linear aliphatic chains.

Raw Material Sources and Sustainability

Cellulose acetate is derived from natural cellulose found in wood pulp and cotton fibers, making it a renewable and biodegradable bioplastic with low environmental impact. Polybutylene succinate (PBS) is synthesized from bio-based succinic acid and 1,4-butanediol, both of which can be produced via microbial fermentation of sugars from renewable biomass. While cellulose acetate boasts superior biodegradability due to its natural origin, PBS offers enhanced mechanical properties and compostability, positioning both as sustainable alternatives depending on application requirements.

Biodegradability and Compostability Differences

Cellulose acetate and polybutylene succinate (PBS) differ significantly in biodegradability and compostability, with PBS exhibiting faster biodegradation rates under industrial composting conditions due to its aliphatic polyester structure. Cellulose acetate, derived from natural cellulose, shows slower biodegradation largely because of its acetyl groups that reduce microbial accessibility, making it less suitable for standard composting processes. PBS is certified as compostable by ASTM D6400, while cellulose acetate requires specialized environments or longer times for effective biodegradation, impacting their suitability for sustainable packaging solutions.

Mechanical Properties and Performance

Cellulose Acetate exhibits high tensile strength and rigidity, making it suitable for applications requiring durable and stiff bioplastic materials. PBS (Polybutylene Succinate) offers superior flexibility and impact resistance, enhancing its performance in products needing elasticity and toughness. Both materials provide good biodegradability, but their mechanical properties differ significantly, influencing their use in packaging, textiles, and film industries.

Processing Methods and Industrial Applications

Cellulose acetate is primarily processed through solvent casting and extrusion, offering excellent film-forming properties ideal for packaging and disposable items. Polybutylene succinate (PBS) utilizes conventional melt processing techniques such as injection molding and blow molding, making it well-suited for durable products like agricultural films and compostable packaging. Industrially, cellulose acetate's biodegradability and transparency favor applications in cigarette filters and textile fibers, whereas PBS's thermal stability and flexibility drive its use in automotive components and food service ware.

Environmental Impact and Life Cycle Assessment

Cellulose acetate and polybutylene succinate (PBS) differ markedly in environmental impact and life cycle assessment, with cellulose acetate derived from renewable cellulose sources exhibiting biodegradability under specific conditions, reducing landfill persistence. PBS, synthesized from renewable feedstocks like sugarcane or corn, offers a fully biodegradable alternative with lower greenhouse gas emissions and energy consumption during production. Life cycle analyses highlight PBS's advantage in carbon footprint reduction and compostability, while cellulose acetate may pose challenges due to potential chemical additives affecting degradation rates.

Cost Analysis and Market Availability

Cellulose acetate generally exhibits higher production costs due to its complex acetylation process, whereas PBS (polybutylene succinate) benefits from more cost-effective microbial fermentation methods. Market availability for cellulose acetate is established primarily in niche sectors like cigarette filters and packaging films, while PBS has gained broader adoption in biodegradable plastics, driven by increasing demand in agriculture and consumer goods. Cost analysis reveals PBS's competitive pricing and expanding supply chains support its scalability compared to the relatively limited commercial scale of cellulose acetate.

Regulatory Compliance and Certifications

Cellulose acetate bioplastics comply with FDA and EU regulations for food contact materials, offering certifications like EN 13432 for compostability and ASTM D6400 for biodegradability. PBS (Polybutylene Succinate) meets global standards such as ISO 17088 for compostability and is approved under the European Standard EN 13432, ensuring regulatory compliance for industrial composting. Both materials support sustainable packaging initiatives while adhering to strict environmental and safety certification requirements.

Future Trends and Innovations in Bioplastics

Cellulose acetate and polybutylene succinate (PBS) are pivotal in advancing bioplastics with cellulose acetate offering exceptional biodegradability and film-forming properties, while PBS excels in mechanical strength and compostability. Future trends emphasize the integration of bio-based feedstocks and enhanced enzymatic degradation techniques for both materials to reduce environmental impact. Innovations include nanocomposite formulations and microbial synthesis pathways that aim to improve performance and scalability in sustainable packaging and automotive applications.

Cellulose Acetate vs PBS Infographic

materialdif.com

materialdif.com