Solvent casting involves dissolving bioplastic polymers in a solvent and then evaporating the solvent to form thin films, allowing precise control over thickness and transparency. Thermoforming heats bioplastic sheets until pliable and then shapes them using molds, making it ideal for producing durable, three-dimensional packaging. Both methods offer distinct advantages, with solvent casting suited for delicate applications and thermoforming preferred for robust, high-volume manufacturing.

Table of Comparison

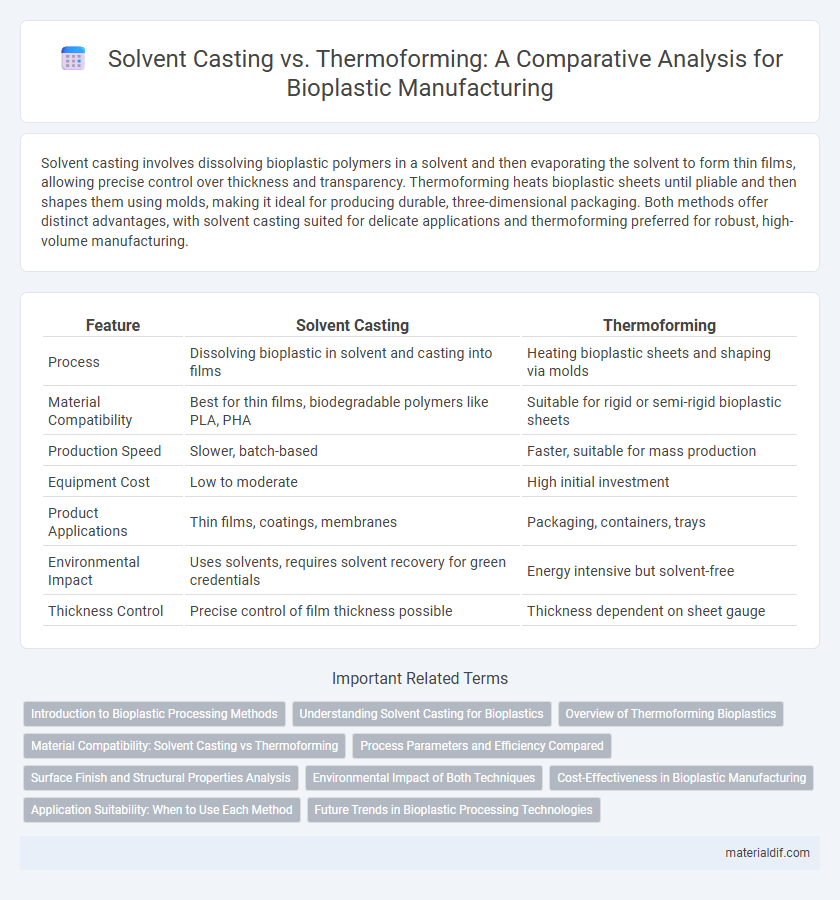

| Feature | Solvent Casting | Thermoforming |

|---|---|---|

| Process | Dissolving bioplastic in solvent and casting into films | Heating bioplastic sheets and shaping via molds |

| Material Compatibility | Best for thin films, biodegradable polymers like PLA, PHA | Suitable for rigid or semi-rigid bioplastic sheets |

| Production Speed | Slower, batch-based | Faster, suitable for mass production |

| Equipment Cost | Low to moderate | High initial investment |

| Product Applications | Thin films, coatings, membranes | Packaging, containers, trays |

| Environmental Impact | Uses solvents, requires solvent recovery for green credentials | Energy intensive but solvent-free |

| Thickness Control | Precise control of film thickness possible | Thickness dependent on sheet gauge |

Introduction to Bioplastic Processing Methods

Solvent casting involves dissolving bioplastic polymers in a solvent to create thin films through evaporation, allowing precise control over film thickness and composition. Thermoforming heats bioplastic sheets until pliable, then molds them into desired shapes using pressure or vacuum, making it suitable for producing rigid or semi-rigid packaging. Both methods are essential in bioplastic manufacturing, with solvent casting favored for flexible applications and thermoforming optimized for structural products.

Understanding Solvent Casting for Bioplastics

Solvent casting for bioplastics involves dissolving biopolymer materials in suitable solvents to create a homogeneous solution, which is then poured into molds and dried to form thin, uniform films. This technique excels in producing high-precision, flexible bioplastic sheets with controlled thickness and excellent clarity, making it ideal for packaging and biomedical applications. The process allows for precise manipulation of polymer properties but requires careful solvent removal to ensure environmental safety and product integrity.

Overview of Thermoforming Bioplastics

Thermoforming bioplastics involves heating biopolymer sheets to a pliable temperature before shaping them into specific molds, enabling efficient production of durable, lightweight packaging and containers. This process ensures uniform material distribution and maintains the biodegradability and compostability features of bioplastics like PLA (polylactic acid) and PHB (polyhydroxybutyrate). Thermoforming offers advantages in scalability and design flexibility compared to solvent casting, making it suitable for industrial applications in food packaging and disposable products.

Material Compatibility: Solvent Casting vs Thermoforming

Solvent casting offers superior material compatibility for bioplastics sensitive to heat, enabling the use of temperature-sensitive polymers without degradation. Thermoforming is better suited for bioplastics with high thermal stability, as the process relies on heating and molding sheets into shapes. Understanding the specific thermal and chemical properties of bioplastic materials is crucial for selecting between solvent casting and thermoforming to ensure optimal product performance.

Process Parameters and Efficiency Compared

Solvent casting involves dissolving bioplastic polymers in a solvent followed by slow evaporation, requiring precise control of drying temperature, solvent concentration, and evaporation rate to achieve uniform film thickness and mechanical properties. Thermoforming uses heat and pressure to shape bioplastic sheets rapidly, with key parameters including forming temperature, heating time, and mold design, optimizing cycle time and material utilization for higher production efficiency. Compared to solvent casting, thermoforming offers faster processing speeds and scalability but may face challenges in achieving the same fine surface finish and molecular orientation inherent to solvent-cast films.

Surface Finish and Structural Properties Analysis

Solvent casting produces bioplastic films with a smooth, uniform surface finish ideal for packaging and coatings but often exhibits lower mechanical strength and flexibility compared to thermoformed counterparts. Thermoforming enhances structural properties by subjecting bioplastic sheets to heat and pressure, resulting in improved impact resistance and rigidity while maintaining acceptable surface quality for containers and trays. Surface finish in thermoforming tends to be slightly textured due to mold patterns, whereas solvent casting offers finer detail resolution but less durability.

Environmental Impact of Both Techniques

Solvent casting in bioplastic production often involves the use of volatile organic compounds (VOCs) that pose environmental hazards and require careful waste management. Thermoforming, by contrast, employs heat to shape bioplastic sheets, resulting in lower emissions and reduced chemical waste. The energy consumption of thermoforming is generally higher, but its overall environmental footprint is minimized by avoiding toxic solvents, making it a more sustainable choice for large-scale bioplastic manufacturing.

Cost-Effectiveness in Bioplastic Manufacturing

Solvent casting offers low initial equipment costs and flexibility in producing thin bioplastic films but incurs higher labor expenses and longer production times, impacting overall cost-effectiveness. Thermoforming involves greater upfront investment in molds and machinery but enables faster production rates and reduced labor costs, making it more economical for large-scale bioplastic manufacturing. Choosing between solvent casting and thermoforming depends on production volume, with solvent casting suited for small runs and thermoforming providing cost advantages in mass production.

Application Suitability: When to Use Each Method

Solvent casting is ideal for producing thin, flexible bioplastic films with precise thickness control, making it suitable for packaging, biomedical devices, and sensors. Thermoforming excels in creating rigid, three-dimensional bioplastic products like trays, containers, and disposable cutlery due to its ability to shape heated sheets into durable forms. Choosing between these methods depends on the required product flexibility, structural complexity, and production volume.

Future Trends in Bioplastic Processing Technologies

Emerging trends in bioplastic processing emphasize solvent casting for its precision in creating thin films with enhanced barrier properties, making it ideal for medical and packaging applications. Thermoforming advances focus on integrating biodegradable polymers with improved thermal stability, enabling large-scale production of eco-friendly containers and trays. Future developments prioritize hybrid techniques combining solvent casting and thermoforming to optimize material performance, reduce energy consumption, and expand bioplastic applications in sustainable industries.

Solvent casting vs Thermoforming Infographic

materialdif.com

materialdif.com