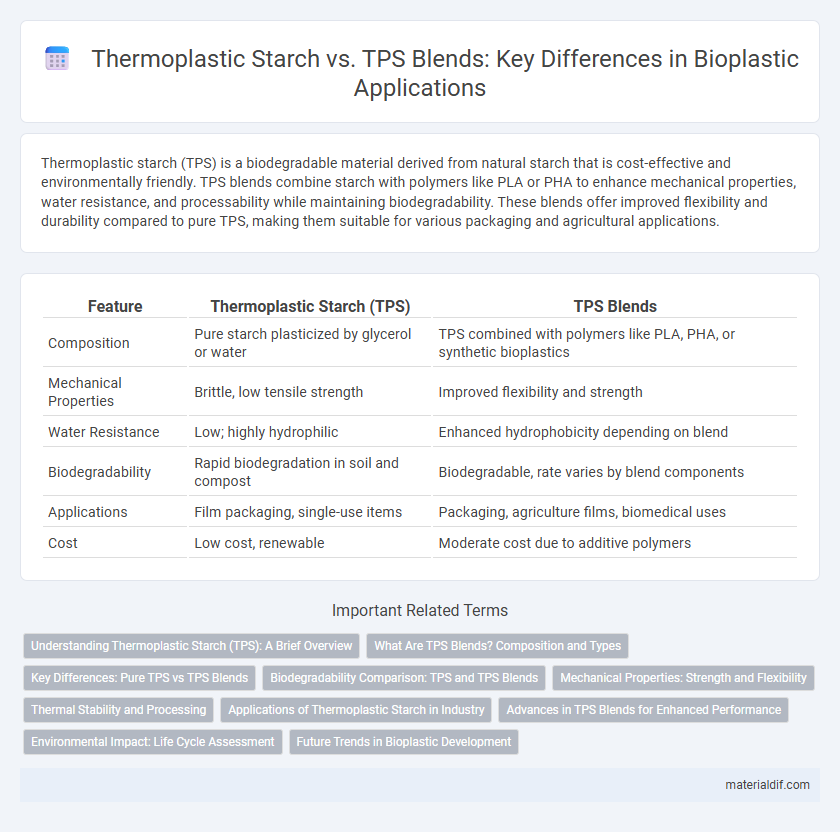

Thermoplastic starch (TPS) is a biodegradable material derived from natural starch that is cost-effective and environmentally friendly. TPS blends combine starch with polymers like PLA or PHA to enhance mechanical properties, water resistance, and processability while maintaining biodegradability. These blends offer improved flexibility and durability compared to pure TPS, making them suitable for various packaging and agricultural applications.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | TPS Blends |

|---|---|---|

| Composition | Pure starch plasticized by glycerol or water | TPS combined with polymers like PLA, PHA, or synthetic bioplastics |

| Mechanical Properties | Brittle, low tensile strength | Improved flexibility and strength |

| Water Resistance | Low; highly hydrophilic | Enhanced hydrophobicity depending on blend |

| Biodegradability | Rapid biodegradation in soil and compost | Biodegradable, rate varies by blend components |

| Applications | Film packaging, single-use items | Packaging, agriculture films, biomedical uses |

| Cost | Low cost, renewable | Moderate cost due to additive polymers |

Understanding Thermoplastic Starch (TPS): A Brief Overview

Thermoplastic starch (TPS) is a biodegradable polymer derived from renewable starch sources such as corn, potato, or cassava, which becomes pliable when heated with plasticizers like glycerol. Unlike conventional plastics, TPS offers enhanced environmental benefits due to its biodegradability and reduced carbon footprint, making it a promising alternative in sustainable packaging. When blended with other biopolymers or additives, TPS blends improve mechanical properties and moisture resistance, expanding their applications in various industries.

What Are TPS Blends? Composition and Types

TPS blends combine thermoplastic starch with polymers like polyvinyl alcohol (PVA), polylactic acid (PLA), or polyethylene to enhance mechanical properties and water resistance. These blends typically consist of 50-70% starch and 30-50% synthetic or biodegradable polymers, tailored to improve flexibility, durability, and biodegradability. Common TPS blend types include TPS/PVA for improved film-forming ability and TPS/PLA for increased biodegradability in packaging applications.

Key Differences: Pure TPS vs TPS Blends

Pure Thermoplastic Starch (TPS) exhibits biodegradability and renewability but suffers from poor mechanical properties and high water sensitivity. TPS blends, often combined with polymers like PLA or PHA, enhance strength, flexibility, and moisture resistance while maintaining biodegradability. The integration of synthetic or natural polymers in TPS blends results in improved thermal stability and processability, making them more suitable for diverse packaging applications.

Biodegradability Comparison: TPS and TPS Blends

Thermoplastic starch (TPS) exhibits rapid biodegradability due to its natural polymer structure, breaking down efficiently in soil and compost environments within weeks. TPS blends, often combined with synthetic polymers or other biopolymers, show varied biodegradability rates depending on the blend ratio and compatibility, with some formulations achieving enhanced mechanical properties but reduced degradation speed. Research indicates that optimizing TPS blend compositions can balance performance and environmental impact, making them suitable for specific applications requiring controlled biodegradability.

Mechanical Properties: Strength and Flexibility

Thermoplastic starch (TPS) exhibits moderate tensile strength but limited flexibility, restricting its use in applications requiring durable materials. TPS blends, formulated by incorporating polymers like polyvinyl alcohol or biodegradable polyesters, significantly enhance mechanical properties by improving both strength and flexibility. These blends achieve an optimal balance suitable for packaging and agricultural films, combining biodegradability with improved performance characteristics.

Thermal Stability and Processing

Thermoplastic starch (TPS) exhibits lower thermal stability compared to TPS blends due to its inherent sensitivity to heat and moisture, leading to degradation at temperatures above 180degC. Incorporating polymers such as polyvinyl alcohol or polycaprolactone in TPS blends enhances thermal resistance, allowing processing temperatures up to 220degC without significant breakdown. Improved thermal stability in TPS blends facilitates broader application in extrusion and injection molding processes, optimizing mechanical properties and durability.

Applications of Thermoplastic Starch in Industry

Thermoplastic starch (TPS) is widely used in the packaging industry for biodegradable films, loose-fill packaging, and food containers due to its renewable origin and compostability. TPS blends with polyesters like PLA enhance mechanical properties, expanding applications to agricultural mulch films and disposable tableware. Industrial use of TPS also includes injection molding for compostable trays and cutlery, catering to the growing demand for sustainable alternatives in consumer goods.

Advances in TPS Blends for Enhanced Performance

Thermoplastic starch (TPS) blends have experienced significant advancements through the incorporation of polymers like polyvinyl alcohol (PVA) and polylactic acid (PLA), which improve mechanical strength and water resistance. Nanofillers such as cellulose nanocrystals and montmorillonite clay are increasingly used to enhance barrier properties and thermal stability in TPS composites. Recent developments in bio-based compatibilizers facilitate better interfacial adhesion, resulting in TPS blends with superior durability and biodegradability for packaging and agricultural applications.

Environmental Impact: Life Cycle Assessment

Thermoplastic starch (TPS) exhibits a lower carbon footprint compared to TPS blends due to its higher biodegradability and use of renewable starch sources, reducing reliance on fossil-based polymers. Life cycle assessment (LCA) studies reveal that TPS blends, often combined with synthetic polymers, have increased environmental burdens in terms of energy consumption and greenhouse gas emissions during production and disposal phases. Biodegradability rates and end-of-life scenarios significantly influence the environmental impact of TPS materials, making pure thermoplastic starch more sustainable in circular economy applications.

Future Trends in Bioplastic Development

Thermoplastic starch (TPS) and TPS blends exhibit significant potential in future bioplastic development due to their biodegradability and renewable resource base. Innovations in enhancing mechanical properties and moisture resistance are driving the adoption of TPS-based materials in packaging and agriculture. The integration of TPS with bio-based polymers like PLA and PHA is expected to advance sustainable material solutions aligned with circular economy goals.

Thermoplastic starch vs TPS blends Infographic

materialdif.com

materialdif.com