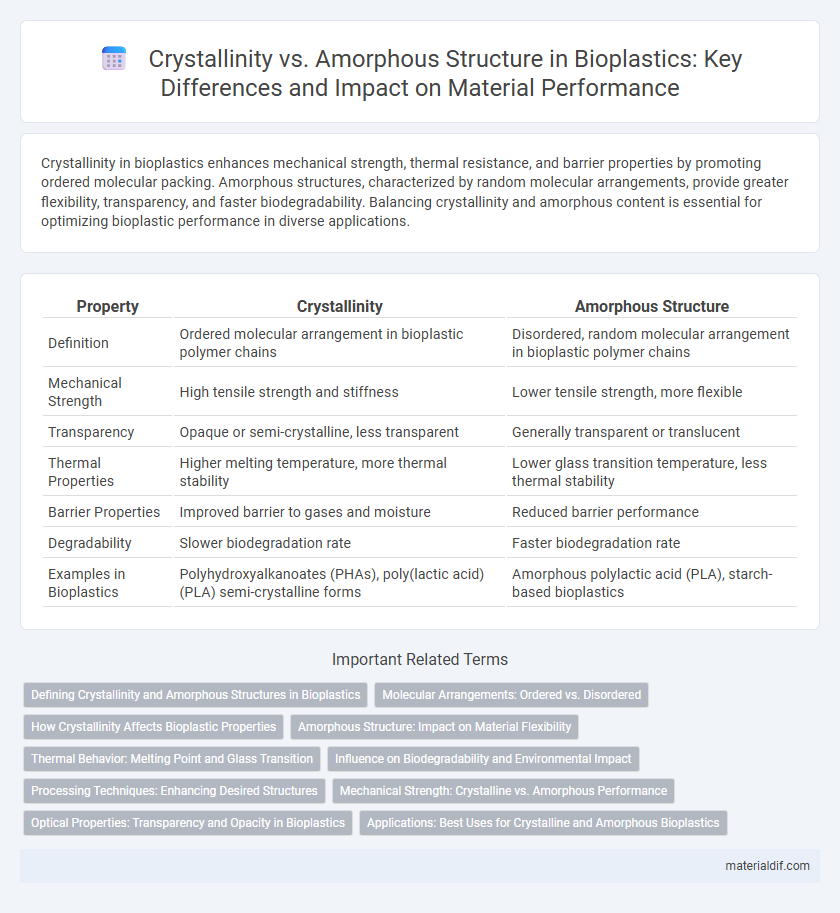

Crystallinity in bioplastics enhances mechanical strength, thermal resistance, and barrier properties by promoting ordered molecular packing. Amorphous structures, characterized by random molecular arrangements, provide greater flexibility, transparency, and faster biodegradability. Balancing crystallinity and amorphous content is essential for optimizing bioplastic performance in diverse applications.

Table of Comparison

| Property | Crystallinity | Amorphous Structure |

|---|---|---|

| Definition | Ordered molecular arrangement in bioplastic polymer chains | Disordered, random molecular arrangement in bioplastic polymer chains |

| Mechanical Strength | High tensile strength and stiffness | Lower tensile strength, more flexible |

| Transparency | Opaque or semi-crystalline, less transparent | Generally transparent or translucent |

| Thermal Properties | Higher melting temperature, more thermal stability | Lower glass transition temperature, less thermal stability |

| Barrier Properties | Improved barrier to gases and moisture | Reduced barrier performance |

| Degradability | Slower biodegradation rate | Faster biodegradation rate |

| Examples in Bioplastics | Polyhydroxyalkanoates (PHAs), poly(lactic acid) (PLA) semi-crystalline forms | Amorphous polylactic acid (PLA), starch-based bioplastics |

Defining Crystallinity and Amorphous Structures in Bioplastics

Crystallinity in bioplastics refers to the ordered, tightly packed molecular arrangement that enhances mechanical strength and thermal resistance. Amorphous structures lack this order, resulting in increased flexibility and transparency but lower rigidity and melting points. Understanding the balance between crystalline and amorphous phases is crucial for tailoring bioplastic properties for specific applications such as packaging, agriculture, and medical devices.

Molecular Arrangements: Ordered vs. Disordered

Bioplastics exhibit varied properties based on their molecular arrangements, where crystallinity denotes highly ordered polymer chains forming dense, tightly packed regions that enhance mechanical strength and chemical resistance. In contrast, amorphous structures feature disordered, randomly oriented polymer chains resulting in flexible, transparent materials with lower density and increased permeability. The degree of crystallinity in bioplastics critically influences thermal stability, biodegradability, and barrier properties, affecting applications in packaging and biomedical fields.

How Crystallinity Affects Bioplastic Properties

Crystallinity in bioplastics significantly influences their mechanical strength, thermal stability, and barrier properties, with higher crystallinity typically enhancing rigidity and resistance to heat and chemicals. Amorphous regions contribute to flexibility and impact resistance but reduce overall tensile strength and increase permeability to gases. Optimizing the balance between crystalline and amorphous phases is crucial for tailoring bioplastic performance in packaging and biomedical applications.

Amorphous Structure: Impact on Material Flexibility

The amorphous structure in bioplastics significantly enhances material flexibility by allowing polymer chains to move more freely compared to crystalline regions. This increased molecular mobility reduces brittleness and improves impact resistance, making the bioplastic more adaptable for applications requiring elasticity and toughness. The lack of ordered crystalline domains also facilitates faster processing and better clarity in bioplastic products.

Thermal Behavior: Melting Point and Glass Transition

Crystallinity in bioplastics significantly influences thermal behavior, with highly crystalline structures exhibiting distinct melting points due to orderly polymer chain arrangements. In contrast, amorphous bioplastics lack a sharp melting point, displaying a glass transition temperature instead, where the polymer shifts from a rigid to a rubbery state. Understanding the balance between crystallinity and amorphous regions helps optimize mechanical properties and thermal stability for applications requiring specific melting or softening temperatures.

Influence on Biodegradability and Environmental Impact

Crystallinity in bioplastics significantly influences biodegradability by affecting polymer chain density and accessibility to microbial enzymes, where higher crystallinity generally reduces degradation rates due to tightly packed molecular structures. Conversely, amorphous bioplastics with less ordered arrangements allow easier enzyme penetration, enhancing biodegradability and reducing environmental persistence. The environmental impact is therefore mitigated by optimizing crystallinity to balance mechanical strength with faster degradation in natural ecosystems.

Processing Techniques: Enhancing Desired Structures

Processing techniques such as controlled cooling rates and annealing optimize crystallinity in bioplastics, enhancing mechanical strength and thermal resistance. Rapid quenching promotes amorphous structures, improving flexibility and impact resistance for specific applications. Adjusting parameters like extrusion temperature and cooling profiles tailors the balance between crystalline and amorphous phases, enabling customized performance in products made from polylactic acid (PLA) and polyhydroxyalkanoates (PHA).

Mechanical Strength: Crystalline vs. Amorphous Performance

Crystallinity in bioplastics enhances mechanical strength by promoting tightly packed polymer chains that improve stiffness and tensile strength. Amorphous structures, characterized by loosely arranged chains, offer greater flexibility and impact resistance but lower overall strength. Balancing crystalline and amorphous phases is crucial for optimizing performance in applications requiring specific mechanical properties.

Optical Properties: Transparency and Opacity in Bioplastics

Crystallinity in bioplastics directly impacts their optical properties, where higher crystallinity typically results in increased opacity due to light scattering from ordered regions, reducing transparency. Amorphous bioplastics exhibit greater transparency as their disordered molecular structure allows light to pass through with minimal scattering. Tailoring the degree of crystallinity enables the customization of bioplastic materials for applications requiring specific transparency levels, such as packaging films or optical lenses.

Applications: Best Uses for Crystalline and Amorphous Bioplastics

Crystalline bioplastics, characterized by their ordered molecular structure, offer high mechanical strength and thermal resistance, making them ideal for applications such as packaging films, durable containers, and automotive parts. Amorphous bioplastics, with their disordered molecular arrangement, provide flexibility, transparency, and faster biodegradability, suited for medical devices, food packaging, and disposable products. Selecting between crystalline and amorphous bioplastics depends on the required durability, clarity, and environmental impact of the end-use application.

Crystallinity vs Amorphous Structure Infographic

materialdif.com

materialdif.com