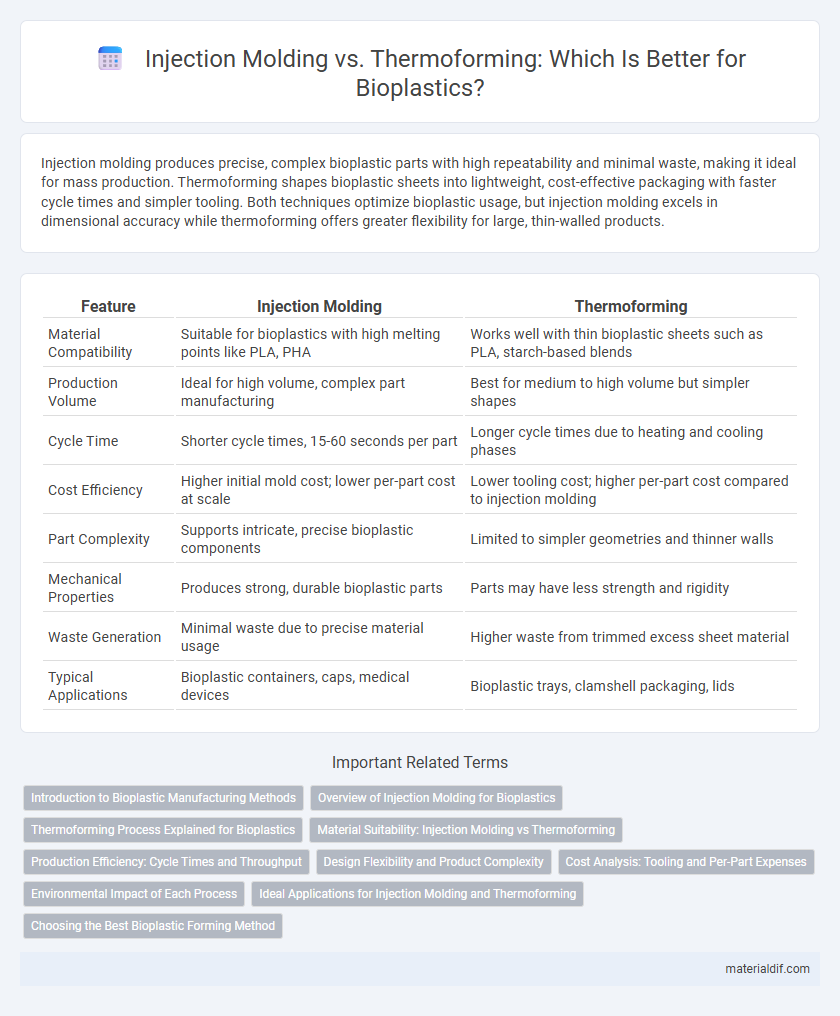

Injection molding produces precise, complex bioplastic parts with high repeatability and minimal waste, making it ideal for mass production. Thermoforming shapes bioplastic sheets into lightweight, cost-effective packaging with faster cycle times and simpler tooling. Both techniques optimize bioplastic usage, but injection molding excels in dimensional accuracy while thermoforming offers greater flexibility for large, thin-walled products.

Table of Comparison

| Feature | Injection Molding | Thermoforming |

|---|---|---|

| Material Compatibility | Suitable for bioplastics with high melting points like PLA, PHA | Works well with thin bioplastic sheets such as PLA, starch-based blends |

| Production Volume | Ideal for high volume, complex part manufacturing | Best for medium to high volume but simpler shapes |

| Cycle Time | Shorter cycle times, 15-60 seconds per part | Longer cycle times due to heating and cooling phases |

| Cost Efficiency | Higher initial mold cost; lower per-part cost at scale | Lower tooling cost; higher per-part cost compared to injection molding |

| Part Complexity | Supports intricate, precise bioplastic components | Limited to simpler geometries and thinner walls |

| Mechanical Properties | Produces strong, durable bioplastic parts | Parts may have less strength and rigidity |

| Waste Generation | Minimal waste due to precise material usage | Higher waste from trimmed excess sheet material |

| Typical Applications | Bioplastic containers, caps, medical devices | Bioplastic trays, clamshell packaging, lids |

Introduction to Bioplastic Manufacturing Methods

Injection molding offers precise shaping of bioplastics by injecting molten material into detailed molds, ideal for complex and high-strength components. Thermoforming involves heating bioplastic sheets until pliable and then vacuum- or pressure-forming them over molds, suitable for large, thin-walled packaging products. Both methods optimize bioplastic use by balancing material properties and product design requirements in sustainable manufacturing.

Overview of Injection Molding for Bioplastics

Injection molding for bioplastics involves melting biodegradable polymer pellets and injecting them into a mold cavity under high pressure, enabling precise and complex shapes with fine detail. This process offers rapid cycle times and minimal material waste, making it highly efficient for mass production of items like packaging, automotive parts, and consumer goods. Key bioplastic materials used include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based blends, which require careful temperature control to maintain material integrity throughout molding.

Thermoforming Process Explained for Bioplastics

Thermoforming for bioplastics involves heating a bioplastic sheet until pliable, then shaping it over a mold using vacuum or pressure. This process is ideal for producing lightweight, custom packaging with excellent material efficiency and minimal waste. Common bioplastics used include PLA and PHA, which maintain biodegradability while offering good formability in thermoforming applications.

Material Suitability: Injection Molding vs Thermoforming

Injection molding is highly suitable for bioplastics with high melt strength and viscosity, such as PLA and PHA, enabling complex and precise shapes. Thermoforming is better suited for bioplastic sheets like PLA and PBAT that soften at lower temperatures, ideal for creating lightweight, large surface-area products. Material selection depends on thermal properties and flow behavior to optimize durability and production efficiency in bioplastic manufacturing.

Production Efficiency: Cycle Times and Throughput

Injection molding of bioplastics offers significantly faster cycle times, often between 15 to 60 seconds per part, enabling higher throughput suitable for mass production. Thermoforming typically involves longer cycle times, ranging from 30 seconds to several minutes, which can reduce production speed for large volumes. The enhanced efficiency of injection molding supports rapid scaling and consistent quality, while thermoforming remains preferable for simpler, larger components despite lower throughput.

Design Flexibility and Product Complexity

Injection molding offers superior design flexibility and supports highly complex bioplastic products with intricate details and tight tolerances, making it ideal for precision components and intricate geometries. Thermoforming is better suited for simpler, larger parts with moderate design complexity, enabling rapid production of thin-walled bioplastic items like trays and packaging. The choice depends on product requirements, with injection molding excelling in customization and structural complexity, while thermoforming provides cost-effective solutions for less complex shapes.

Cost Analysis: Tooling and Per-Part Expenses

Injection molding of bioplastics demands higher initial tooling costs due to complex molds, but offers significantly lower per-part expenses with large production volumes. Thermoforming involves less expensive tooling suitable for simpler shapes, yet per-part costs remain higher, especially for smaller batch sizes. Evaluating cost-effectiveness depends on production scale and product complexity, favoring injection molding for mass production and thermoforming for limited runs.

Environmental Impact of Each Process

Injection molding typically generates less material waste compared to thermoforming due to its precise use of bioplastic pellets and efficient cavity filling. Thermoforming, while faster and lower cost for large parts, often produces more scrap sheets that need recycling or disposal, impacting its environmental footprint. Energy consumption varies, with injection molding requiring higher initial energy but enabling better material reuse and less post-processing waste.

Ideal Applications for Injection Molding and Thermoforming

Injection molding is ideal for producing complex, high-precision bioplastic parts with intricate geometries, suitable for medical devices, automotive components, and consumer electronics casings. Thermoforming excels in creating large, lightweight, and thin-walled bioplastic products such as packaging trays, disposable containers, and agricultural covers. Both techniques optimize bioplastic material properties but cater to different production volumes and design complexities.

Choosing the Best Bioplastic Forming Method

Injection molding offers precise control and efficiency for complex bioplastic shapes, making it ideal for high-volume production with consistent quality. Thermoforming excels in creating large, thin-walled bioplastic products quickly and cost-effectively, suitable for packaging and disposable items. Selecting the best bioplastic forming method depends on product complexity, volume requirements, and desired mechanical properties.

Injection molding vs Thermoforming Infographic

materialdif.com

materialdif.com