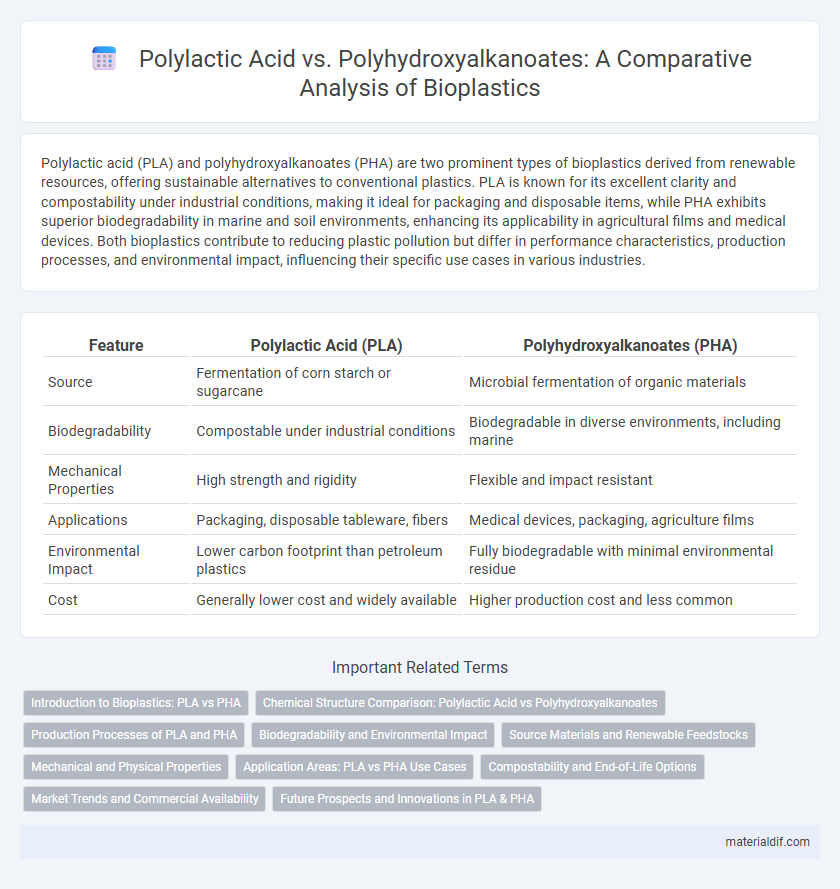

Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are two prominent types of bioplastics derived from renewable resources, offering sustainable alternatives to conventional plastics. PLA is known for its excellent clarity and compostability under industrial conditions, making it ideal for packaging and disposable items, while PHA exhibits superior biodegradability in marine and soil environments, enhancing its applicability in agricultural films and medical devices. Both bioplastics contribute to reducing plastic pollution but differ in performance characteristics, production processes, and environmental impact, influencing their specific use cases in various industries.

Table of Comparison

| Feature | Polylactic Acid (PLA) | Polyhydroxyalkanoates (PHA) |

|---|---|---|

| Source | Fermentation of corn starch or sugarcane | Microbial fermentation of organic materials |

| Biodegradability | Compostable under industrial conditions | Biodegradable in diverse environments, including marine |

| Mechanical Properties | High strength and rigidity | Flexible and impact resistant |

| Applications | Packaging, disposable tableware, fibers | Medical devices, packaging, agriculture films |

| Environmental Impact | Lower carbon footprint than petroleum plastics | Fully biodegradable with minimal environmental residue |

| Cost | Generally lower cost and widely available | Higher production cost and less common |

Introduction to Bioplastics: PLA vs PHA

Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) represent two prominent types of bioplastics derived from renewable resources, with PLA mainly produced from fermented plant starches and PHA synthesized by microbial fermentation of sugars and lipids. PLA is known for its transparent appearance, rigidity, and suitability in packaging and disposable items, while PHA offers superior biodegradability and biocompatibility, making it ideal for medical applications and environmentally sensitive products. Both materials contribute to reducing reliance on fossil fuels and lowering carbon emissions, but their distinct properties influence their application scope and environmental impact.

Chemical Structure Comparison: Polylactic Acid vs Polyhydroxyalkanoates

Polylactic acid (PLA) is a linear aliphatic polyester derived from lactic acid, characterized by repeating units of lactic acid linked through ester bonds, resulting in a rigid and crystalline structure. Polyhydroxyalkanoates (PHAs) consist of hydroxyalkanoate monomers with a variable side chain length, forming a diverse family of biopolyesters with both amorphous and crystalline regions, imparting greater flexibility and biodegradability. The chemical structure of PLA leads to higher tensile strength and brittleness, while PHAs offer tunable material properties due to their heterogeneous monomer composition.

Production Processes of PLA and PHA

Polylactic acid (PLA) is produced primarily through the fermentation of renewable resources like corn starch or sugarcane, where lactic acid is polymerized via ring-opening polymerization to form a biodegradable thermoplastic. Polyhydroxyalkanoates (PHA) are synthesized by microbial fermentation of carbon substrates such as glucose, lipids, or waste oils under nutrient-limited conditions, resulting in intracellular accumulation of PHA granules that are subsequently extracted. The PLA production process is highly dependent on controlled fermentation and chemical catalysis, while PHA production relies on optimizing microbial strains and fermentation parameters for efficient biopolymer synthesis.

Biodegradability and Environmental Impact

Polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are prominent bioplastics known for their biodegradability, but PHA exhibits superior decomposition rates in diverse environments, including marine and soil settings. PLA primarily requires industrial composting facilities to achieve effective biodegradation, whereas PHA can naturally degrade in a broader range of ecosystems without specialized conditions, reducing long-term environmental pollution. The environmental impact of PHA is further minimized by its microbial production process, which often uses renewable resources and results in lower greenhouse gas emissions compared to the fermentation-based synthesis of PLA.

Source Materials and Renewable Feedstocks

Polylactic acid (PLA) is primarily derived from renewable starch-rich crops such as corn, sugarcane, and cassava, making it dependent on agricultural biomass. Polyhydroxyalkanoates (PHAs) are synthesized by microbial fermentation of various renewable feedstocks, including waste oils, organic residues, and sugars, offering more diverse and sustainable input options. The reliance of PHAs on mixed organic waste streams enhances their potential for circular bioeconomy applications compared to the crop-based feedstocks of PLA.

Mechanical and Physical Properties

Polylactic acid (PLA) exhibits high tensile strength and rigidity, making it suitable for applications requiring structural integrity, though it is relatively brittle with low impact resistance. Polyhydroxyalkanoates (PHA) demonstrate greater flexibility, higher impact resistance, and superior biodegradability but generally have lower tensile strength compared to PLA. Both bioplastics differ in thermal properties, with PLA having a higher melting point around 150-160degC and PHA melting at approximately 130degC, influencing their processing and end-use performance.

Application Areas: PLA vs PHA Use Cases

Polylactic acid (PLA) is widely used in packaging, disposable tableware, and medical implants due to its biodegradability and good mechanical properties, making it ideal for short-term applications. Polyhydroxyalkanoates (PHA) are favored in agricultural films, biodegradable plastics for electronics, and drug delivery systems owing to their superior biodegradability in marine environments and compatibility with living tissues. The distinct use cases of PLA and PHA reflect their thermal stability, degradation rates, and biocompatibility, with PLA suited for rigid products and PHA for environmentally sensitive and biomedical applications.

Compostability and End-of-Life Options

Polylactic acid (PLA) is compostable under industrial composting conditions, breaking down within 1 to 3 months, but it has limited degradability in home composting or natural environments. Polyhydroxyalkanoates (PHA) offer more versatile end-of-life options, as they biodegrade effectively in marine, soil, and anaerobic conditions, making them suitable for broader compostability applications. Both bioplastics contribute to reducing plastic waste, but PHA's complete biodegradability across diverse environments provides a significant advantage in sustainable waste management.

Market Trends and Commercial Availability

Polylactic acid (PLA) dominates the bioplastic market due to its cost-effectiveness and extensive commercial availability, with annual production exceeding 300,000 tons. Polyhydroxyalkanoates (PHA) remain less prevalent but are gaining traction for their biodegradability and suitability for medical and packaging applications, supported by emerging low-cost fermentation technologies. Market trends indicate increasing investment in PHA to overcome production challenges, aiming to capture niche sectors where environmental compliance and biodegradability are critical.

Future Prospects and Innovations in PLA & PHA

Polylactic acid (PLA) shows promising advancements through improved crystallinity and blending technologies, enhancing its mechanical properties and expanding its use in packaging and biomedical applications. Polyhydroxyalkanoates (PHA) benefit from breakthroughs in microbial fermentation and genetic engineering, enabling cost-effective production and tailored polymer properties for diverse industrial uses. Future innovations in PLA and PHA focus on sustainability, recycling methods, and integrating bio-based additives to boost performance and biodegradability, driving the global shift toward eco-friendly plastics.

Polylactic acid vs Polyhydroxyalkanoates Infographic

materialdif.com

materialdif.com