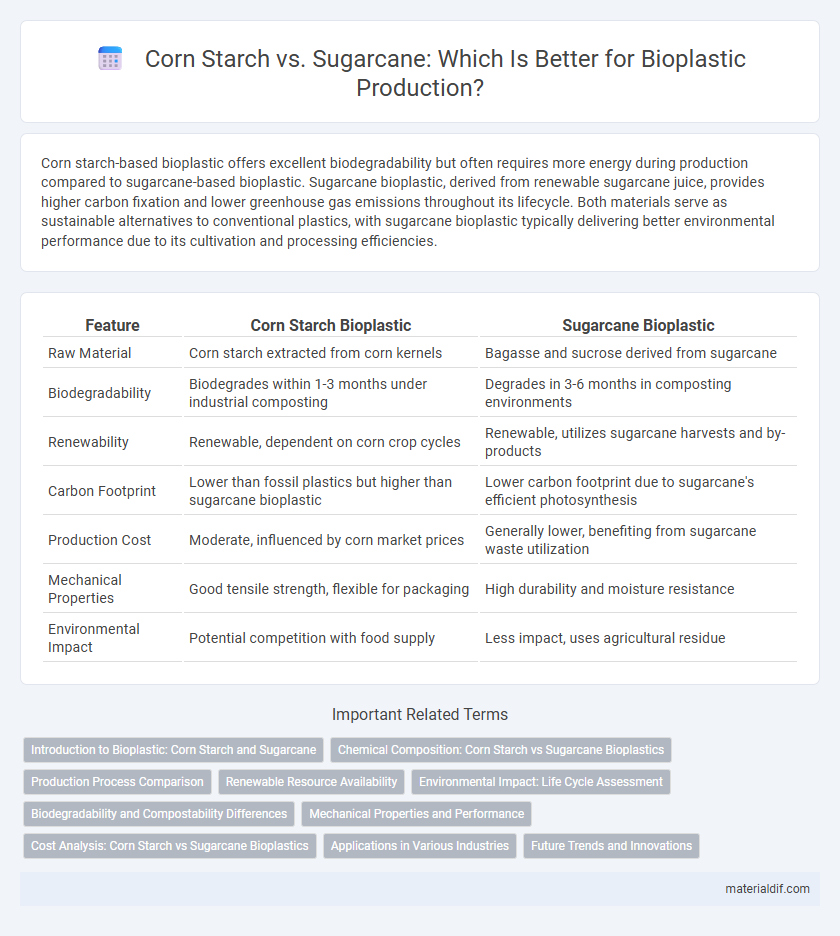

Corn starch-based bioplastic offers excellent biodegradability but often requires more energy during production compared to sugarcane-based bioplastic. Sugarcane bioplastic, derived from renewable sugarcane juice, provides higher carbon fixation and lower greenhouse gas emissions throughout its lifecycle. Both materials serve as sustainable alternatives to conventional plastics, with sugarcane bioplastic typically delivering better environmental performance due to its cultivation and processing efficiencies.

Table of Comparison

| Feature | Corn Starch Bioplastic | Sugarcane Bioplastic |

|---|---|---|

| Raw Material | Corn starch extracted from corn kernels | Bagasse and sucrose derived from sugarcane |

| Biodegradability | Biodegrades within 1-3 months under industrial composting | Degrades in 3-6 months in composting environments |

| Renewability | Renewable, dependent on corn crop cycles | Renewable, utilizes sugarcane harvests and by-products |

| Carbon Footprint | Lower than fossil plastics but higher than sugarcane bioplastic | Lower carbon footprint due to sugarcane's efficient photosynthesis |

| Production Cost | Moderate, influenced by corn market prices | Generally lower, benefiting from sugarcane waste utilization |

| Mechanical Properties | Good tensile strength, flexible for packaging | High durability and moisture resistance |

| Environmental Impact | Potential competition with food supply | Less impact, uses agricultural residue |

Introduction to Bioplastic: Corn Starch and Sugarcane

Bioplastics derived from corn starch and sugarcane offer sustainable alternatives to conventional plastics, utilizing renewable biomass sources. Corn starch bioplastics are primarily produced through the fermentation of glucose obtained from corn kernels, resulting in polylactic acid (PLA) with strong biodegradability. Sugarcane-based bioplastics leverage sucrose-rich juice for bio-polymerization processes, yielding materials like polyethylene from bioethanol, renowned for high carbon sequestration and reduced greenhouse gas emissions.

Chemical Composition: Corn Starch vs Sugarcane Bioplastics

Corn starch bioplastics primarily consist of amylose and amylopectin polysaccharides, which provide a biodegradable matrix with good film-forming properties. Sugarcane bioplastics are derived from sucrose-rich juice, converted into bioethanol and subsequently into polyethylene or polyhydroxyalkanoates, offering enhanced durability and moisture resistance. The chemical composition differences influence biodegradability rates and mechanical strength, with corn starch bioplastics degrading faster but sugarcane bioplastics demonstrating superior tensile properties.

Production Process Comparison

Corn starch bioplastic production involves extracting starch from corn kernels, followed by gelatinization and plasticization using additives like glycerol to form a biodegradable polymer. Sugarcane bioplastic production primarily derives from fermenting sugarcane juice into ethanol, which is then polymerized into polylactic acid (PLA), a compostable bioplastic. The corn starch process is more direct in transforming raw material into bioplastic, while sugarcane production utilizes fermentation steps, impacting energy consumption and carbon footprint differently.

Renewable Resource Availability

Corn starch and sugarcane both serve as renewable resources for bioplastic production, but sugarcane offers higher biomass yield per hectare and faster growth cycles. Sugarcane cultivation typically demands less freshwater compared to corn, enhancing its sustainability profile in regions with water scarcity. The abundant availability of sugarcane in tropical climates supports large-scale, consistent bioplastic feedstock supply, while corn's extensive cultivation in temperate zones ensures diverse geographic sourcing opportunities.

Environmental Impact: Life Cycle Assessment

Corn starch-based bioplastics exhibit higher environmental impacts in water usage and eutrophication due to intensive irrigation and fertilizer application during cultivation. Sugarcane-derived bioplastics demonstrate lower greenhouse gas emissions and better energy efficiency, benefiting from renewable energy input and efficient agricultural practices in life cycle assessments. Both feedstocks contribute to reducing fossil fuel dependency, but sugarcane provides a more sustainable option in terms of overall environmental footprint.

Biodegradability and Compostability Differences

Corn starch-based bioplastics typically exhibit faster biodegradability due to their polysaccharide structure, breaking down efficiently in industrial composting environments within 60 to 90 days. Sugarcane-derived bioplastics, primarily produced as polylactic acid (PLA), also show strong compostability but often require specific conditions such as elevated temperatures above 58degC for effective degradation, potentially taking up to six months. Variations in biodegradability and compostability between corn starch and sugarcane bioplastics impact their environmental footprint and suitability for different waste management systems.

Mechanical Properties and Performance

Corn starch-based bioplastics exhibit moderate tensile strength and flexibility but tend to have lower impact resistance compared to sugarcane-derived bioplastics. Sugarcane bioplastics generally demonstrate superior mechanical properties, including higher durability, better moisture resistance, and enhanced performance under diverse environmental conditions. These differences make sugarcane bioplastics more suitable for applications requiring robust and long-lasting materials.

Cost Analysis: Corn Starch vs Sugarcane Bioplastics

Corn starch-based bioplastics generally exhibit lower production costs due to the widespread availability and established supply chains of corn in key agricultural regions. Sugarcane bioplastics, while often more expensive, benefit from higher biomass yield per hectare and faster growth cycles, potentially offsetting initial production expenses. Cost analysis must consider regional factors, feedstock prices, and processing technologies, as these variables significantly impact the economic feasibility of corn starch versus sugarcane bioplastic production.

Applications in Various Industries

Corn starch-based bioplastics are widely utilized in packaging, agriculture, and disposable tableware due to their biodegradability and cost-effectiveness. Sugarcane-derived bioplastics, especially polylactic acid (PLA), find extensive applications in the automotive sector, medical equipment, and food packaging owing to their superior strength and compostability. Both materials contribute to reducing fossil fuel dependence, with sugarcane offering a higher carbon sequestration potential in industrial uses.

Future Trends and Innovations

Corn starch bioplastics are evolving with enhanced biodegradability and cost-efficient production methods, positioning them as a sustainable solution for single-use packaging. Sugarcane-based bioplastics leverage advanced fermentation techniques and genetic engineering to increase yield and reduce carbon footprints, making them a preferred choice in the automotive and consumer goods industries. Future trends emphasize integrating nanotechnology and bio-composites to improve mechanical properties and expand applications across flexible electronics and medical devices.

Corn starch vs Sugarcane Infographic

materialdif.com

materialdif.com