Thermoplastic starch (TPS) and polylactic acid (PLA) are prominent bioplastics used in PET applications, with TPS derived from renewable starch sources and offering cost-effective biodegradability. PLA, synthesized from fermented plant sugars, provides superior mechanical strength, clarity, and thermal resistance compared to TPS. While TPS excels in compostability and flexibility, PLA is preferred for packaging that requires durability and high-performance characteristics.

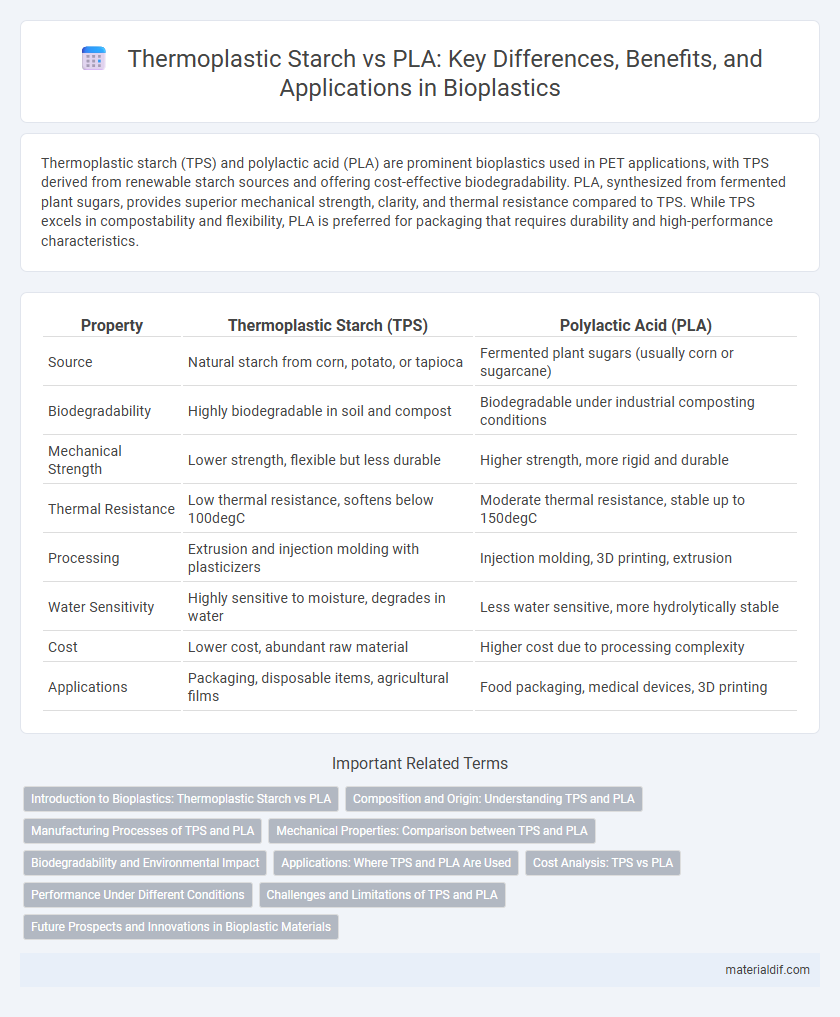

Table of Comparison

| Property | Thermoplastic Starch (TPS) | Polylactic Acid (PLA) |

|---|---|---|

| Source | Natural starch from corn, potato, or tapioca | Fermented plant sugars (usually corn or sugarcane) |

| Biodegradability | Highly biodegradable in soil and compost | Biodegradable under industrial composting conditions |

| Mechanical Strength | Lower strength, flexible but less durable | Higher strength, more rigid and durable |

| Thermal Resistance | Low thermal resistance, softens below 100degC | Moderate thermal resistance, stable up to 150degC |

| Processing | Extrusion and injection molding with plasticizers | Injection molding, 3D printing, extrusion |

| Water Sensitivity | Highly sensitive to moisture, degrades in water | Less water sensitive, more hydrolytically stable |

| Cost | Lower cost, abundant raw material | Higher cost due to processing complexity |

| Applications | Packaging, disposable items, agricultural films | Food packaging, medical devices, 3D printing |

Introduction to Bioplastics: Thermoplastic Starch vs PLA

Thermoplastic starch (TPS) and polylactic acid (PLA) represent two prominent categories of bioplastics derived from renewable resources, offering sustainable alternatives to conventional petroleum-based plastics. TPS is produced by processing starch from crops like corn or potatoes, resulting in a biodegradable material with applications in packaging and agricultural films. PLA, synthesized through fermentation of plant sugars into lactic acid and subsequent polymerization, provides higher mechanical strength and thermal resistance, making it suitable for healthcare devices and food containers.

Composition and Origin: Understanding TPS and PLA

Thermoplastic starch (TPS) is derived from natural starch sources like corn, potatoes, and cassava, composed mainly of amylose and amylopectin that are plasticized to enhance flexibility. Polylactic acid (PLA) originates from fermented plant sugars, primarily corn or sugarcane, consisting of lactic acid polymers known for their rigidity and biodegradability. Understanding the composition and natural origin of TPS and PLA is crucial for applications requiring specific mechanical properties and environmental considerations.

Manufacturing Processes of TPS and PLA

Thermoplastic starch (TPS) is manufactured by gelatinizing starch with heat and mechanical shear, often incorporating plasticizers like glycerol to improve flexibility, enabling processing through extrusion or injection molding. Polylactic acid (PLA) production involves fermenting renewable resources such as corn or sugarcane to produce lactic acid, which undergoes polymerization through ring-opening or condensation methods, followed by extrusion or injection molding. TPS offers simpler, lower-temperature processing conditions compared to PLA, which requires more complex chemical synthesis steps for polymerization.

Mechanical Properties: Comparison between TPS and PLA

Thermoplastic starch (TPS) exhibits lower tensile strength and modulus compared to polylactic acid (PLA), impacting its suitability for load-bearing applications. PLA demonstrates superior mechanical properties with higher stiffness and better elongation at break, making it ideal for rigid packaging. TPS, while more flexible and biodegradable, often requires blending or reinforcement to match PLA's performance levels in mechanical durability.

Biodegradability and Environmental Impact

Thermoplastic starch (TPS) is highly biodegradable and breaks down rapidly in soil and compost environments, minimizing long-term pollution compared to PLA, which requires industrial composting facilities for efficient degradation. PLA, derived from renewable resources, offers lower greenhouse gas emissions during production but poses challenges in biodegradability under natural conditions, potentially contributing to microplastic pollution if not properly managed. Choosing TPS over PLA can reduce environmental impact in ecosystems lacking adequate composting infrastructure, making TPS more suitable for short-lived disposable products.

Applications: Where TPS and PLA Are Used

Thermoplastic Starch (TPS) is widely used in packaging materials, agricultural films, and disposable items due to its biodegradability and cost-effectiveness. Polylactic Acid (PLA) finds applications in food packaging, medical implants, and 3D printing because of its strength, clarity, and compostability. Both materials serve as sustainable alternatives in single-use products and agricultural sectors, with PLA dominating in high-performance uses.

Cost Analysis: TPS vs PLA

Thermoplastic starch (TPS) offers a cost advantage over polylactic acid (PLA) due to its lower raw material expenses derived from abundant agricultural sources like corn and potato starch. Manufacturing TPS requires less energy-intensive processing compared to PLA, further reducing overall production costs. However, PLA's higher price is often justified by its superior mechanical properties and biodegradability in industrial composting environments.

Performance Under Different Conditions

Thermoplastic starch (TPS) exhibits high biodegradability and excels in humidity-rich environments due to its hydrophilic nature but shows reduced mechanical strength and thermal resistance compared to PLA. Polylactic acid (PLA) offers superior tensile strength, stiffness, and heat resistance, maintaining performance in dry and moderate temperature conditions, yet it degrades slower under composting circumstances. The choice between TPS and PLA depends on specific application requirements where moisture exposure and thermal stability are critical factors.

Challenges and Limitations of TPS and PLA

Thermoplastic starch (TPS) faces challenges including high moisture sensitivity and poor mechanical strength, limiting its durability and application range compared to PLA. Polylactic acid (PLA) suffers from low heat resistance and brittleness, constraining its use in high-temperature environments and flexible packaging. Both TPS and PLA require improvements in biodegradability rates and cost-effectiveness to enhance commercial viability and environmental impact.

Future Prospects and Innovations in Bioplastic Materials

Thermoplastic starch (TPS) offers significant biodegradability and low cost, but PLA (polylactic acid) provides superior mechanical properties and easier processing, driving its widespread adoption in packaging and medical fields. Emerging innovations focus on enhancing TPS's water resistance and mechanical strength through blending with PLA and incorporating nanomaterials, aiming to create fully biodegradable composites with improved performance. Future prospects in bioplastic materials emphasize sustainable feedstocks, advanced biodegradation pathways, and scalable production methods to meet growing environmental regulations and market demand.

Thermoplastic Starch vs PLA Infographic

materialdif.com

materialdif.com