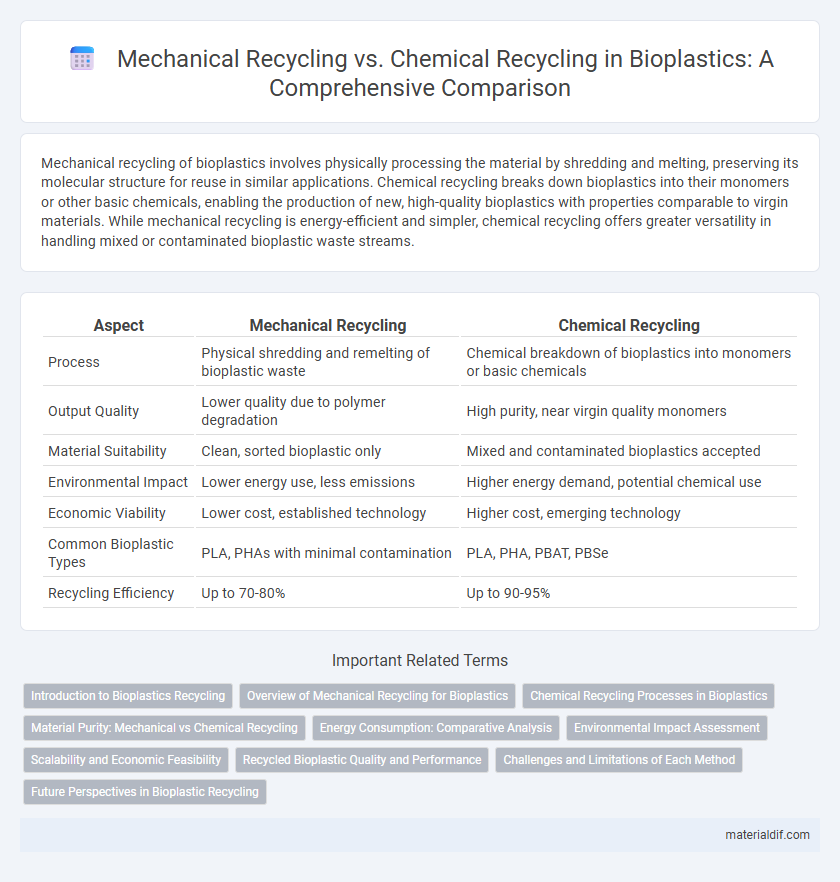

Mechanical recycling of bioplastics involves physically processing the material by shredding and melting, preserving its molecular structure for reuse in similar applications. Chemical recycling breaks down bioplastics into their monomers or other basic chemicals, enabling the production of new, high-quality bioplastics with properties comparable to virgin materials. While mechanical recycling is energy-efficient and simpler, chemical recycling offers greater versatility in handling mixed or contaminated bioplastic waste streams.

Table of Comparison

| Aspect | Mechanical Recycling | Chemical Recycling |

|---|---|---|

| Process | Physical shredding and remelting of bioplastic waste | Chemical breakdown of bioplastics into monomers or basic chemicals |

| Output Quality | Lower quality due to polymer degradation | High purity, near virgin quality monomers |

| Material Suitability | Clean, sorted bioplastic only | Mixed and contaminated bioplastics accepted |

| Environmental Impact | Lower energy use, less emissions | Higher energy demand, potential chemical use |

| Economic Viability | Lower cost, established technology | Higher cost, emerging technology |

| Common Bioplastic Types | PLA, PHAs with minimal contamination | PLA, PHA, PBAT, PBSe |

| Recycling Efficiency | Up to 70-80% | Up to 90-95% |

Introduction to Bioplastics Recycling

Mechanical recycling of bioplastics involves physically processing waste materials into new products while preserving polymer structures, making it cost-effective and environmentally friendly for common bioplastics like PLA and PHA. Chemical recycling breaks down bioplastics into monomers or other basic chemicals, enabling the production of high-purity raw materials suitable for complex or contaminated waste streams. Both methods enhance the circular economy by reducing landfill waste and dependence on fossil resources, with mechanical recycling favored for its simplicity and chemical recycling offering broader versatility.

Overview of Mechanical Recycling for Bioplastics

Mechanical recycling of bioplastics involves physically processing waste materials through sorting, shredding, and melting without altering their chemical structure, preserving the polymer's original properties. This method is energy-efficient and cost-effective, suitable for bioplastics like PLA and PBAT, but it faces limitations regarding contamination and polymer degradation over multiple cycles. Advances in sorting technologies and the development of compatible bioplastic blends enhance the feasibility of mechanical recycling in reducing environmental impact.

Chemical Recycling Processes in Bioplastics

Chemical recycling processes in bioplastics involve breaking down polymer chains into monomers or valuable chemicals through techniques like hydrolysis, glycolysis, and pyrolysis. This approach enables the recovery of high-purity materials suitable for producing new bioplastics, reducing reliance on virgin resources and minimizing waste. Compared to mechanical recycling, chemical recycling effectively handles mixed or contaminated bioplastic waste streams, enhancing circular economy potential.

Material Purity: Mechanical vs Chemical Recycling

Mechanical recycling preserves the original polymer structure but often results in lower material purity due to contaminants and polymer degradation during processing. Chemical recycling breaks down bioplastics into monomers or basic chemicals, enabling the removal of impurities and producing higher-purity materials suitable for virgin-quality bioplastic production. Material purity in chemical recycling supports enhanced performance and broader reuse options compared to the more limited purity achievable through mechanical recycling.

Energy Consumption: Comparative Analysis

Mechanical recycling of bioplastics generally consumes significantly less energy compared to chemical recycling, as it involves simpler processes like shredding and melting without breaking molecular bonds. Chemical recycling requires higher energy input to depolymerize bioplastics into monomers or other chemicals, often involving elevated temperatures and pressure conditions. Energy consumption metrics indicate mechanical recycling can reduce energy use by up to 70% compared to chemical methods, enhancing overall sustainability in bioplastic waste management.

Environmental Impact Assessment

Mechanical recycling of bioplastics typically results in lower energy consumption and reduced greenhouse gas emissions compared to chemical recycling, which requires higher temperatures and more complex processes. Environmental Impact Assessment (EIA) studies reveal that mechanical recycling generates less toxic waste and conserves resources more efficiently. Chemical recycling, while enabling recovery of monomers for high-quality bioplastics, often has a larger carbon footprint and greater environmental risks due to solvent use and energy intensity.

Scalability and Economic Feasibility

Mechanical recycling of bioplastics offers high scalability due to established infrastructure and lower operational costs, making it economically feasible for large-scale processing of homogeneous waste streams. Chemical recycling, while capable of handling mixed or contaminated bioplastics and producing higher-quality monomers, faces challenges in scalability because of energy-intensive processes and higher capital investment requirements. Cost-effectiveness of chemical recycling improves with technological advancements and economies of scale but currently remains less competitive compared to mechanical methods in mainstream bioplastic recycling.

Recycled Bioplastic Quality and Performance

Mechanical recycling of bioplastics retains the polymer's original molecular structure, preserving mechanical properties such as tensile strength and flexibility, but is limited by contamination and polymer degradation over multiple cycles. Chemical recycling breaks down bioplastics into monomers, enabling the production of high-purity polymers with properties comparable to virgin materials, thus ensuring superior recycled bioplastic quality and performance. The choice between mechanical and chemical recycling impacts the sustainability and application range of recycled bioplastics in industries demanding consistent material standards.

Challenges and Limitations of Each Method

Mechanical recycling of bioplastics faces challenges such as contamination, degradation of polymer quality, and limited recyclability of mixed plastic streams, resulting in lower material performance for subsequent use. Chemical recycling offers the advantage of breaking down polymers into monomers for repolymerization but involves high energy consumption, costly processes, and potential environmental impacts from chemical use. Both methods struggle with the complexity of bioplastic compositions and the lack of standardized recycling infrastructure, limiting their efficiency and scalability in circular waste management.

Future Perspectives in Bioplastic Recycling

Mechanical recycling of bioplastics preserves polymer integrity and is currently more energy-efficient, but faces challenges with contamination and limited plastic blends. Chemical recycling shows promise for future bioplastic circularity by breaking polymers into monomers, enabling material recovery and producing high-purity outputs suitable for new bioplastics. Emerging innovations in catalytic processes and enzymatic depolymerization are expected to enhance chemical recycling scalability and economic viability, driving improved sustainability in bioplastic waste management.

Mechanical recycling vs Chemical recycling Infographic

materialdif.com

materialdif.com