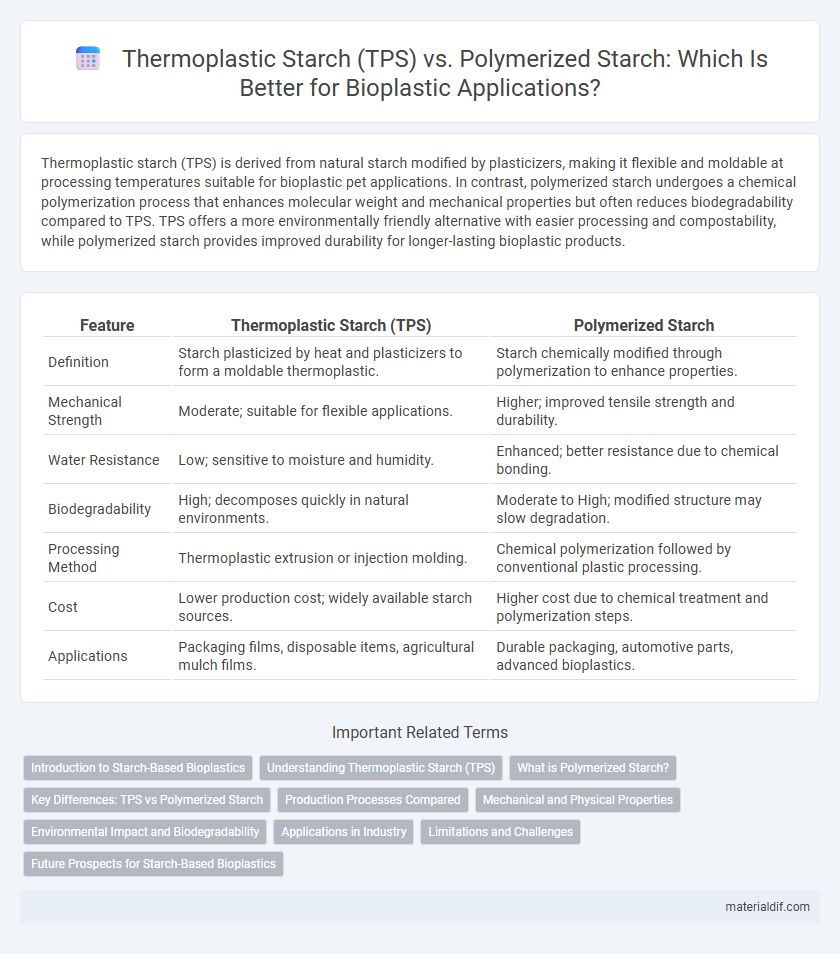

Thermoplastic starch (TPS) is derived from natural starch modified by plasticizers, making it flexible and moldable at processing temperatures suitable for bioplastic pet applications. In contrast, polymerized starch undergoes a chemical polymerization process that enhances molecular weight and mechanical properties but often reduces biodegradability compared to TPS. TPS offers a more environmentally friendly alternative with easier processing and compostability, while polymerized starch provides improved durability for longer-lasting bioplastic products.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Polymerized Starch |

|---|---|---|

| Definition | Starch plasticized by heat and plasticizers to form a moldable thermoplastic. | Starch chemically modified through polymerization to enhance properties. |

| Mechanical Strength | Moderate; suitable for flexible applications. | Higher; improved tensile strength and durability. |

| Water Resistance | Low; sensitive to moisture and humidity. | Enhanced; better resistance due to chemical bonding. |

| Biodegradability | High; decomposes quickly in natural environments. | Moderate to High; modified structure may slow degradation. |

| Processing Method | Thermoplastic extrusion or injection molding. | Chemical polymerization followed by conventional plastic processing. |

| Cost | Lower production cost; widely available starch sources. | Higher cost due to chemical treatment and polymerization steps. |

| Applications | Packaging films, disposable items, agricultural mulch films. | Durable packaging, automotive parts, advanced bioplastics. |

Introduction to Starch-Based Bioplastics

Thermoplastic starch (TPS) is a biodegradable material derived from native starch that is processed with plasticizers, enabling it to be molded and shaped like conventional plastics. Polymerized starch, on the other hand, involves chemically modifying starch molecules to improve mechanical properties and water resistance, resulting in more durable starch-based bioplastics. Both TPS and polymerized starch serve as sustainable alternatives to petroleum-based plastics, with TPS offering ease of processing and polymerized starch providing enhanced performance for various packaging applications.

Understanding Thermoplastic Starch (TPS)

Thermoplastic starch (TPS) is a biodegradable material derived from starch that undergoes a plasticization process, enabling it to be molded and extruded like conventional plastics. Unlike polymerized starch, which retains its natural granular structure, TPS is produced by heating starch with plasticizers such as glycerol, resulting in a thermoplastic material with enhanced flexibility and processability. TPS is widely used in sustainable packaging due to its renewable origin, biodegradability, and potential to reduce reliance on fossil-based plastics.

What is Polymerized Starch?

Polymerized starch is a biopolymer derived from natural starch that undergoes chemical modification to form longer, more stable molecular chains enhancing its mechanical properties and water resistance. Unlike thermoplastic starch (TPS), which is produced by plasticizing native starch with plasticizers and heat, polymerized starch involves polymerization reactions such as grafting or crosslinking to improve durability and thermal stability. This modification makes polymerized starch suitable for more robust applications in biodegradable packaging and environmentally friendly composites.

Key Differences: TPS vs Polymerized Starch

Thermoplastic starch (TPS) is produced by plasticizing native starch with plasticizers under heat and shear, resulting in a material that can be melted and molded like conventional thermoplastics, while polymerized starch involves chemically modifying starch to create a stable, high molecular weight polymer with enhanced mechanical properties. TPS is biodegradable, cost-effective, and easily processable but often exhibits poor moisture resistance and mechanical strength compared to polymerized starch that offers superior durability and water resistance due to its chemically cross-linked structure. The key differences lie in processing methods, material properties, and end-use applications, with TPS preferred for short-term, disposable items and polymerized starch suitable for more demanding, durable bioplastic products.

Production Processes Compared

Thermoplastic starch (TPS) is produced by gelatinizing native starch with plasticizers under heat and shear, enabling it to be processed through conventional thermoplastic methods like extrusion and injection molding. Polymerized starch involves chemical modification processes such as graft copolymerization or crosslinking, resulting in enhanced mechanical and barrier properties but requiring more complex synthesis steps. TPS offers a simpler, more cost-effective production route, while polymerized starch demands advanced chemical treatments for improved performance in bioplastic applications.

Mechanical and Physical Properties

Thermoplastic starch (TPS) exhibits high flexibility and good tensile strength due to its plasticized structure, making it suitable for packaging applications requiring moderate durability. Polymerized starch, formed through chemical cross-linking, provides enhanced mechanical stability and resistance to moisture, resulting in stronger films with improved dimensional stability. TPS typically has lower crystallinity and moisture resistance compared to polymerized starch, affecting its long-term physical performance under humid conditions.

Environmental Impact and Biodegradability

Thermoplastic starch (TPS) is produced by plasticizing starch with glycerol and water, resulting in a biodegradable material that decomposes rapidly under composting conditions, significantly reducing landfill accumulation. In contrast, polymerized starch involves chemically modifying starch to enhance mechanical properties but may decrease biodegradability due to introduced synthetic polymers, leading to longer environmental persistence. TPS offers a more eco-friendly alternative with lower carbon footprint and faster biodegradation rates, making it preferable for sustainable packaging applications.

Applications in Industry

Thermoplastic starch (TPS) is widely used in packaging, agricultural films, and disposable items due to its biodegradability and ease of processing with conventional equipment. Polymerized starch, on the other hand, offers enhanced mechanical properties and water resistance, making it suitable for applications in textile finishes, adhesives, and biomedical materials. Industrial adoption of TPS is favored for cost-effective, short-term use products, while polymerized starch targets more durable, performance-critical sectors.

Limitations and Challenges

Thermoplastic starch (TPS) faces significant challenges such as high moisture sensitivity, poor mechanical strength, and thermal instability, limiting its application in durable products. Polymerized starch improves structural integrity but involves complex synthesis processes that increase production costs and reduce scalability. Both materials suffer from limited water resistance, which restricts their use in high-humidity or wet environments.

Future Prospects for Starch-Based Bioplastics

Thermoplastic starch (TPS) offers enhanced processability and biodegradability compared to polymerized starch, making it a promising candidate for sustainable packaging solutions. Advances in starch modification and blending techniques aim to improve the mechanical properties and water resistance of TPS, expanding its applicability in various industries. The integration of TPS with other bio-based polymers and nanomaterials is expected to drive innovation and meet growing environmental regulations in the bioplastic market.

Thermoplastic starch (TPS) vs Polymerized starch Infographic

materialdif.com

materialdif.com