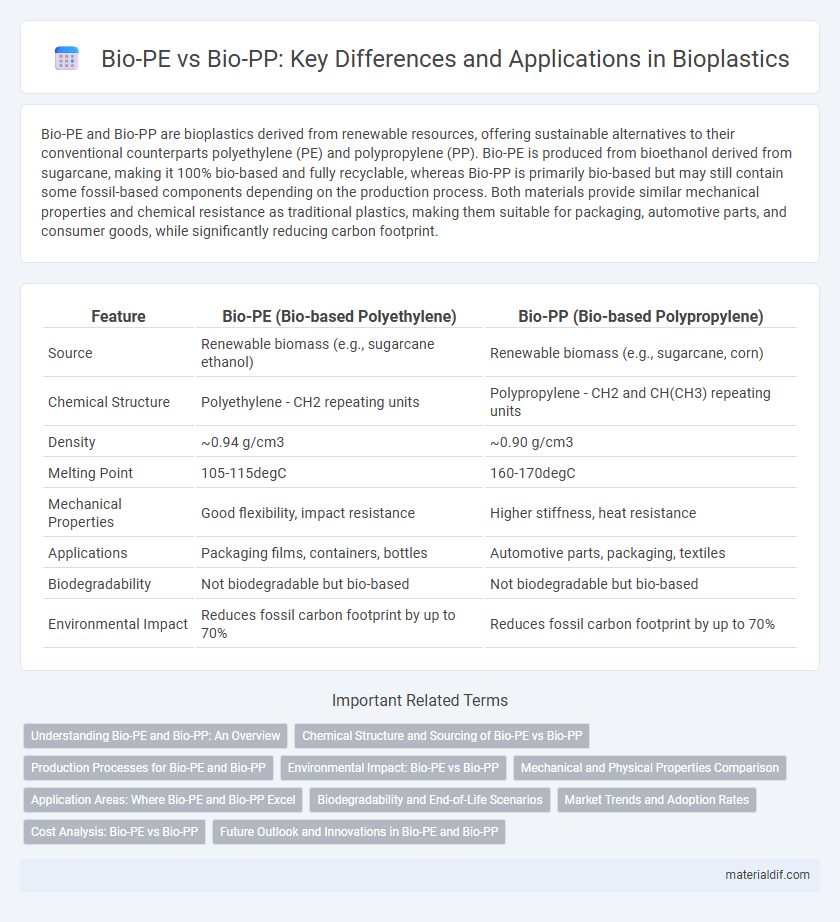

Bio-PE and Bio-PP are bioplastics derived from renewable resources, offering sustainable alternatives to their conventional counterparts polyethylene (PE) and polypropylene (PP). Bio-PE is produced from bioethanol derived from sugarcane, making it 100% bio-based and fully recyclable, whereas Bio-PP is primarily bio-based but may still contain some fossil-based components depending on the production process. Both materials provide similar mechanical properties and chemical resistance as traditional plastics, making them suitable for packaging, automotive parts, and consumer goods, while significantly reducing carbon footprint.

Table of Comparison

| Feature | Bio-PE (Bio-based Polyethylene) | Bio-PP (Bio-based Polypropylene) |

|---|---|---|

| Source | Renewable biomass (e.g., sugarcane ethanol) | Renewable biomass (e.g., sugarcane, corn) |

| Chemical Structure | Polyethylene - CH2 repeating units | Polypropylene - CH2 and CH(CH3) repeating units |

| Density | ~0.94 g/cm3 | ~0.90 g/cm3 |

| Melting Point | 105-115degC | 160-170degC |

| Mechanical Properties | Good flexibility, impact resistance | Higher stiffness, heat resistance |

| Applications | Packaging films, containers, bottles | Automotive parts, packaging, textiles |

| Biodegradability | Not biodegradable but bio-based | Not biodegradable but bio-based |

| Environmental Impact | Reduces fossil carbon footprint by up to 70% | Reduces fossil carbon footprint by up to 70% |

Understanding Bio-PE and Bio-PP: An Overview

Bio-PE (bio-based polyethylene) and Bio-PP (bio-based polypropylene) are sustainably produced polymers derived primarily from renewable sources such as sugarcane ethanol, offering alternatives to traditional fossil fuel-based plastics. Bio-PE is highly resistant to moisture and chemicals, making it ideal for packaging and agricultural films, while Bio-PP provides excellent heat resistance and mechanical durability, suitable for automotive parts and consumer goods. Both bioplastics maintain the chemical structure of their conventional counterparts, ensuring compatibility with existing recycling streams and processing technologies.

Chemical Structure and Sourcing of Bio-PE vs Bio-PP

Bio-PE (Bio-based Polyethylene) is derived from bioethanol primarily sourced from sugarcane, featuring a simple linear hydrocarbon chain composed of ethylene monomers (C2H4), which provides excellent chemical inertness and flexibility. Bio-PP (Bio-based Polypropylene), synthesized from bio-propylene obtained via advanced catalytic processes or fermentation pathways, exhibits a methyl group attached to every other carbon atom in its polymer chain (C3H6 monomers), resulting in higher rigidity and thermal resistance compared to Bio-PE. Both bioplastics differ chemically; Bio-PE is a homopolymer of ethylene with a saturated hydrocarbon backbone, whereas Bio-PP's repeating units contain a sidestep methyl substituent influencing its mechanical properties and sourcing complexity.

Production Processes for Bio-PE and Bio-PP

Bio-PE is produced by polymerizing ethylene derived from bioethanol, typically sourced from sugarcane or corn, through fermentation and dehydration processes. Bio-PP production involves polymerizing propylene that can be obtained from bio-naphtha or bio-methanol derived via biomass gasification or catalytic conversion technologies. Both production processes utilize renewable feedstocks but differ in the intermediate chemicals and catalytic polymerization techniques employed to generate bio-based polyethylene and polypropylene.

Environmental Impact: Bio-PE vs Bio-PP

Bio-PE and Bio-PP are both bioplastics derived from renewable resources, but Bio-PE typically exhibits a lower carbon footprint due to its production from sugarcane ethanol, which absorbs CO2 during cultivation. Life cycle assessments reveal Bio-PE generates fewer greenhouse gas emissions compared to Bio-PP, which is often produced from biomass via more energy-intensive processes. Despite both being biodegradable alternatives to fossil-based plastics, Bio-PE generally offers superior environmental benefits in terms of energy consumption and greenhouse gas reductions.

Mechanical and Physical Properties Comparison

Bio-PE (bio-polyethylene) demonstrates greater flexibility and impact resistance compared to Bio-PP (bio-polypropylene), which exhibits higher tensile strength and rigidity. Bio-PP offers better heat resistance and a higher melting point, making it suitable for applications requiring thermal stability. Both bioplastics provide excellent chemical resistance, but Bio-PE's lower density results in lighter end products.

Application Areas: Where Bio-PE and Bio-PP Excel

Bio-PE excels in packaging, agricultural films, and consumer goods due to its flexibility and moisture resistance, making it ideal for products requiring durability and recyclability. Bio-PP is preferred in automotive parts, textiles, and rigid packaging because of its superior heat resistance, stiffness, and chemical stability. Both bioplastics offer sustainable alternatives with distinct application advantages based on their mechanical and thermal properties.

Biodegradability and End-of-Life Scenarios

Bio-PE (bio-based polyethylene) is chemically identical to conventional polyethylene, making it non-biodegradable but fully recyclable through existing plastic recycling streams. Bio-PP (bio-based polypropylene) shares similar properties with traditional polypropylene, resulting in limited biodegradability and compatibility with standard recycling systems. Both materials primarily rely on mechanical recycling or energy recovery for end-of-life management, as biodegradation is not a viable disposal option.

Market Trends and Adoption Rates

Bio-PE leads the bioplastic market with higher adoption due to its compatibility with existing polyethylene processing and widespread use in packaging applications, driving a compound annual growth rate (CAGR) of approximately 15%. Bio-PP, while emerging more slowly, gains traction owing to its superior mechanical properties and increasing interest in automotive and consumer goods sectors, reflecting a CAGR near 10%. Global demand for bio-based polymers continues to rise, with Bio-PE capturing the majority share amid growing sustainability regulations and consumer preference for circular economy solutions.

Cost Analysis: Bio-PE vs Bio-PP

Bio-PE generally presents a lower production cost compared to Bio-PP due to more established manufacturing processes and higher feedstock availability. Bio-PP often incurs higher expenses because of its newer technology requirements and limited raw material supply chains. Cost efficiency in Bio-PE makes it more attractive for large-scale applications, while Bio-PP may deliver better performance features but at a premium price.

Future Outlook and Innovations in Bio-PE and Bio-PP

Bio-PE and Bio-PP represent key advancements in sustainable polymer technologies, with Bio-PE benefiting from established production processes and a growing feedstock base of renewable sugars and ethanol. Innovation in Bio-PP is accelerating as research targets improved catalytic efficiency and the integration of bio-based propylene derived from lignocellulosic biomass, aiming to expand its commercial viability. Future outlook projects significant growth driven by increasing demand for biodegradable packaging and automotive components, emphasizing the role of bio-based polymers in achieving circular economy goals.

Bio-PE vs Bio-PP Infographic

materialdif.com

materialdif.com