Thermoplastic starch is a biodegradable polymer that softens when heated and can be reshaped multiple times, making it ideal for sustainable packaging applications. In contrast, thermosetting starch undergoes a chemical change during curing, resulting in a rigid, insoluble material that cannot be remelted or reshaped. Understanding the differences between thermoplastic and thermosetting starch is crucial for selecting the appropriate bioplastic type for various industrial uses.

Table of Comparison

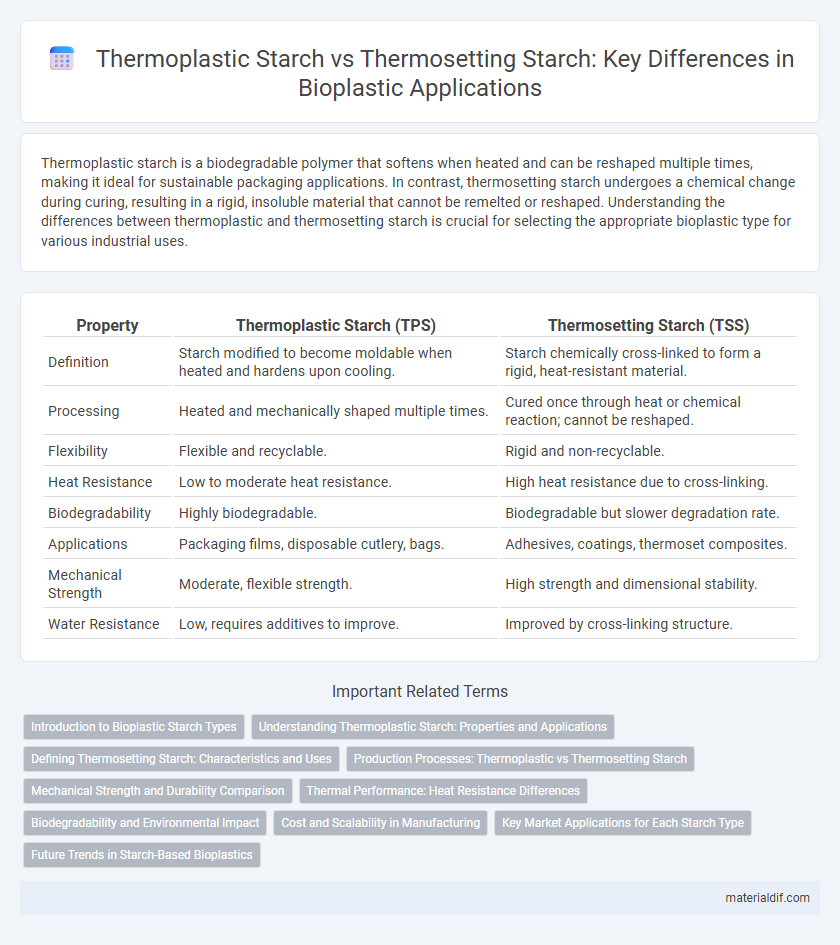

| Property | Thermoplastic Starch (TPS) | Thermosetting Starch (TSS) |

|---|---|---|

| Definition | Starch modified to become moldable when heated and hardens upon cooling. | Starch chemically cross-linked to form a rigid, heat-resistant material. |

| Processing | Heated and mechanically shaped multiple times. | Cured once through heat or chemical reaction; cannot be reshaped. |

| Flexibility | Flexible and recyclable. | Rigid and non-recyclable. |

| Heat Resistance | Low to moderate heat resistance. | High heat resistance due to cross-linking. |

| Biodegradability | Highly biodegradable. | Biodegradable but slower degradation rate. |

| Applications | Packaging films, disposable cutlery, bags. | Adhesives, coatings, thermoset composites. |

| Mechanical Strength | Moderate, flexible strength. | High strength and dimensional stability. |

| Water Resistance | Low, requires additives to improve. | Improved by cross-linking structure. |

Introduction to Bioplastic Starch Types

Thermoplastic starch (TPS) is a biodegradable material derived from native starch that becomes moldable upon heating and can be reshaped multiple times, making it ideal for flexible packaging and disposable products. In contrast, thermosetting starch undergoes a curing process that creates irreversible cross-linked bonds, resulting in a rigid, heat-resistant structure often used in durable items and adhesives. Both starch types contribute to sustainable bioplastic development by reducing reliance on fossil-based plastics and enhancing environmental biodegradability.

Understanding Thermoplastic Starch: Properties and Applications

Thermoplastic starch exhibits unique properties such as biodegradability, flexibility, and processability, making it suitable for producing environmentally friendly packaging films, disposable items, and agricultural mulch films. Unlike thermosetting starch, which forms irreversible cross-links and hard, inflexible materials, thermoplastic starch can be melted and remolded multiple times due to its starch plasticization under heat and moisture. Its compatibility with other biodegradable polymers enhances mechanical strength and water resistance, expanding applications in sustainable bioplastics.

Defining Thermosetting Starch: Characteristics and Uses

Thermosetting starch is a type of bioplastic made by chemically modifying starch to form irreversible, cross-linked structures that provide enhanced heat resistance and structural stability. Unlike thermoplastic starch, which softens upon heating and can be remolded, thermosetting starch cures into a rigid, durable material ideal for applications such as biodegradable packaging, disposable utensils, and agricultural films. Its permanent set and resistance to deformation under heat make it suitable for products requiring dimensional stability and mechanical strength.

Production Processes: Thermoplastic vs Thermosetting Starch

Thermoplastic starch is produced by plasticizing starch with water, glycerol, or other plasticizers under heat and shear, enabling it to melt and be reshaped multiple times. Thermosetting starch undergoes irreversible chemical cross-linking during curing, forming a rigid, insoluble network that cannot be remelted or reshaped after setting. Production of thermoplastic starch involves extrusion or injection molding, while thermosetting starch requires curing processes such as heat treatment or chemical agents to achieve permanent hardening.

Mechanical Strength and Durability Comparison

Thermoplastic starch exhibits moderate mechanical strength and flexibility, making it suitable for applications requiring some deformation without breaking. Thermosetting starch, due to its cross-linked polymer network, offers significantly higher mechanical strength and durability, providing resistance to heat and chemical degradation. The rigid, irreversible bonding in thermosetting starch ensures long-term stability and structural integrity under mechanical stress.

Thermal Performance: Heat Resistance Differences

Thermoplastic starch exhibits moderate heat resistance, softening at temperatures around 150-170degC, which limits its use in high-temperature applications. Thermosetting starch, through chemical cross-linking, offers superior thermal stability and maintains structural integrity beyond 200degC, making it ideal for heat-resistant bioplastic products. The enhanced heat resistance of thermosetting starch results from irreversible curing processes that prevent melting, in contrast to the reversible softening behavior of thermoplastic starch.

Biodegradability and Environmental Impact

Thermoplastic starch (TPS) exhibits high biodegradability, breaking down rapidly in soil and compost environments due to its reversible melting and processing capabilities. In contrast, thermosetting starch is cross-linked and rigid, resulting in lower biodegradability and prolonged environmental persistence. The environmental impact of TPS is significantly lower, making it a preferable choice for sustainable bioplastic production compared to the more resistant and less eco-friendly thermosetting starch.

Cost and Scalability in Manufacturing

Thermoplastic starch offers lower production costs due to its simple processing methods and compatibility with existing thermoplastic manufacturing equipment, enabling large-scale, cost-effective production. Thermosetting starch requires more complex chemical crosslinking processes, resulting in higher costs and limited scalability for mass manufacturing. The scalability advantage of thermoplastic starch makes it more favorable for commercial bioplastic applications.

Key Market Applications for Each Starch Type

Thermoplastic starch is widely utilized in packaging materials, agricultural films, and disposable tableware due to its biodegradability and ease of processing through injection molding and extrusion. Thermosetting starch finds key applications in durable composites, adhesives, and coatings where enhanced mechanical strength and water resistance are required. Market demand for thermoplastic starch rises in single-use consumer goods, while thermosetting starch grows in construction and automotive sectors for eco-friendly material replacements.

Future Trends in Starch-Based Bioplastics

Thermoplastic starch (TPS) dominates the starch-based bioplastic market due to its biodegradability and ease of processing with conventional plastic equipment. Future trends emphasize enhancing TPS with bio-fillers and nanomaterials to improve mechanical strength and water resistance, targeting packaging and agricultural applications. Research on thermosetting starch focuses on developing cross-linked networks for higher thermal stability and durability, aiming for automotive and construction sectors where long-term performance is crucial.

Thermoplastic starch vs Thermosetting starch Infographic

materialdif.com

materialdif.com