Corn-based bioplastic offers high biodegradability and is derived from starch-rich kernels, making it suitable for producing packaging and disposable cutlery. Sugarcane-based bioplastic, primarily composed of ethanol-derived polymers, provides a renewable and carbon-neutral alternative with a lower environmental impact due to efficient photosynthesis and rapid growth cycles. Both materials contribute to reducing fossil fuel dependency, but sugarcane-based bioplastics typically demonstrate better greenhouse gas emission profiles and energy balance during production.

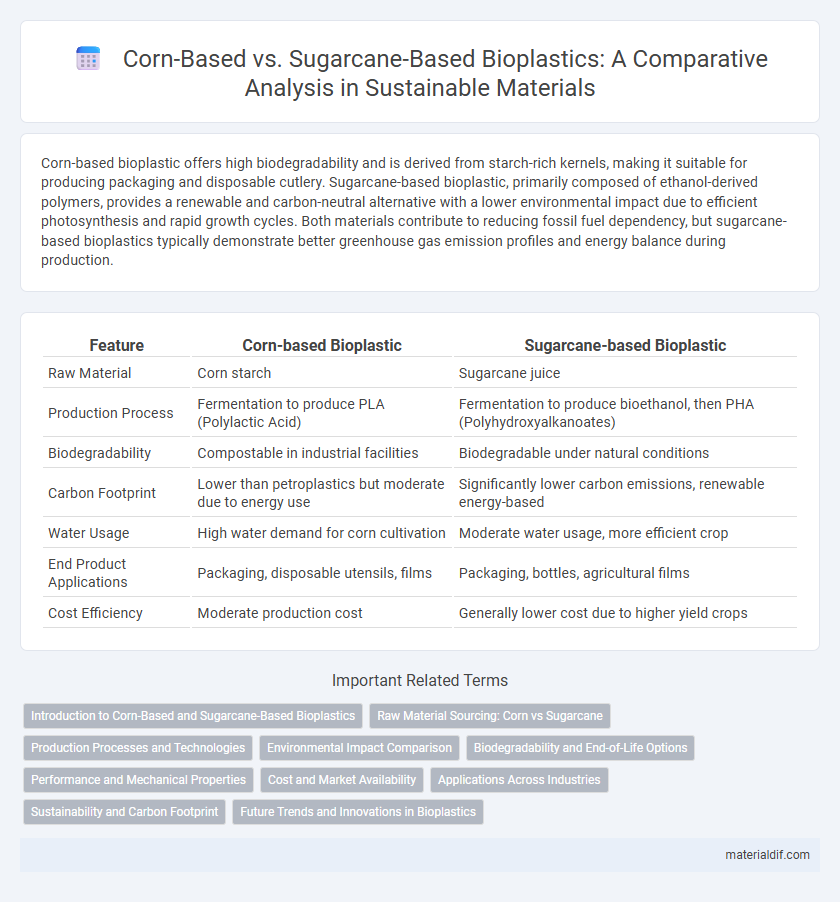

Table of Comparison

| Feature | Corn-based Bioplastic | Sugarcane-based Bioplastic |

|---|---|---|

| Raw Material | Corn starch | Sugarcane juice |

| Production Process | Fermentation to produce PLA (Polylactic Acid) | Fermentation to produce bioethanol, then PHA (Polyhydroxyalkanoates) |

| Biodegradability | Compostable in industrial facilities | Biodegradable under natural conditions |

| Carbon Footprint | Lower than petroplastics but moderate due to energy use | Significantly lower carbon emissions, renewable energy-based |

| Water Usage | High water demand for corn cultivation | Moderate water usage, more efficient crop |

| End Product Applications | Packaging, disposable utensils, films | Packaging, bottles, agricultural films |

| Cost Efficiency | Moderate production cost | Generally lower cost due to higher yield crops |

Introduction to Corn-Based and Sugarcane-Based Bioplastics

Corn-based bioplastics primarily use polylactic acid (PLA) derived from fermenting corn starch, offering biodegradability and renewable resource advantages. Sugarcane-based bioplastics typically utilize bio-polyethylene (Bio-PE) produced through the fermentation and polymerization of sugarcane ethanol, providing a carbon-neutral alternative to conventional plastics. Both materials support reduced reliance on fossil fuels, but differ in feedstock characteristics, production processes, and end-of-life environmental impacts.

Raw Material Sourcing: Corn vs Sugarcane

Corn-based bioplastic sourcing relies heavily on maize crops predominantly grown in the United States, where intensive farming practices can impact soil health and water resources. Sugarcane-based bioplastic raw materials are primarily sourced from tropical regions such as Brazil and India, benefiting from high yield per hectare and renewable harvesting cycles that enhance sustainability. The lifecycle emissions and resource inputs of sugarcane cultivation generally present a lower environmental footprint compared to corn production, influencing the overall ecological impact of the bioplastic.

Production Processes and Technologies

Corn-based bioplastic production primarily involves fermenting corn starch into glucose followed by microbial fermentation to produce polylactic acid (PLA), using technologies such as enzymatic hydrolysis and advanced bioreactors for scalability. Sugarcane-based bioplastic synthesis utilizes the sucrose from sugarcane juice, processed through fermentation techniques to generate bioethanol and subsequently biopolymers like polyethylene (bio-PE) via catalytic polymerization. Both production processes emphasize renewable feedstocks but differ in enzymatic breakdown efficiency and feedstock availability, influencing energy consumption and carbon footprint in bioplastic manufacturing.

Environmental Impact Comparison

Corn-based bioplastic production consumes significant amounts of freshwater and relies heavily on fertilizers and pesticides, contributing to soil degradation and greenhouse gas emissions. Sugarcane-based bioplastic offers a more sustainable alternative by utilizing a fast-growing crop with higher photosynthetic efficiency, resulting in lower carbon footprints and reduced water usage. Lifecycle assessments indicate sugarcane bioplastics generate fewer emissions and less environmental strain compared to corn-derived counterparts.

Biodegradability and End-of-Life Options

Corn-based bioplastic typically exhibits faster biodegradability under industrial composting conditions due to its high starch content, enabling more efficient microbial breakdown. Sugarcane-based bioplastic offers diverse end-of-life options, including mechanical recycling and composting, supported by its robust polyethylene matrix that enhances durability while maintaining compostability. Both materials contribute to reducing plastic pollution, but corn-based bioplastics generally degrade more rapidly in controlled settings, whereas sugarcane bioplastics balance biodegradability with greater physical resilience.

Performance and Mechanical Properties

Corn-based bioplastic typically exhibits higher tensile strength and better flexibility due to its amylose content, making it suitable for applications requiring durability and stretchability. Sugarcane-based bioplastic, derived mainly from bagasse, offers good impact resistance and moisture barrier properties but can be less flexible compared to corn-based variants. Both types provide biodegradability benefits, yet corn-based bioplastics often outperform in mechanical stability while sugarcane-based plastics excel in resistance to environmental stress.

Cost and Market Availability

Corn-based bioplastic typically has higher production costs due to the intensive use of genetically modified crops and food-grade raw materials, but it benefits from established industrial infrastructure and widespread market availability, especially in North America. Sugarcane-based bioplastic offers lower production costs driven by abundant tropical crop yield and renewable carbon sources, leading to increased adoption in Latin America and parts of Asia with expanding market presence. Both materials face supply chain considerations, though sugarcane's rapid biomass growth and lower input costs often provide competitive pricing advantages in emerging bioplastic markets.

Applications Across Industries

Corn-based bioplastics are widely utilized in packaging, agriculture mulch films, and disposable tableware due to their excellent biodegradability and compatibility with food contact applications. Sugarcane-based bioplastics find extensive use in automotive parts, consumer electronics casings, and durable goods because of their superior mechanical strength and renewable carbon content. Both materials enhance sustainability efforts across industries by reducing reliance on fossil fuels and lowering greenhouse gas emissions during production.

Sustainability and Carbon Footprint

Corn-based bioplastic typically has a higher carbon footprint due to the intensive use of fertilizers and water in corn cultivation, whereas sugarcane-based bioplastic benefits from the crop's rapid growth and high photosynthetic efficiency, leading to lower greenhouse gas emissions. Sugarcane bioplastics offer better sustainability profiles as sugarcane cultivation often involves less land and water use compared to corn, contributing to reduced environmental impact. Lifecycle assessments consistently show that sugarcane-based bioplastics generate fewer carbon emissions and preserve natural resources more effectively than their corn-based counterparts.

Future Trends and Innovations in Bioplastics

Corn-based bioplastics are advancing through enhanced starch conversion techniques that improve biodegradability and mechanical strength, positioning them for broader applications in packaging and agriculture. Sugarcane-based bioplastics benefit from innovations in fermentation technology and genetic engineering, leading to higher yield biopolymers with reduced carbon footprints. Both materials are driving future trends in sustainable production, emphasizing circular economy integration and carbon-neutral manufacturing processes.

Corn-based bioplastic vs Sugarcane-based bioplastic Infographic

materialdif.com

materialdif.com