Cellulose acetate, derived from cellulose and acetic acid, offers enhanced durability and resistance to moisture compared to cellophane, which is made from regenerated cellulose. This makes cellulose acetate ideal for applications requiring longer-lasting, water-resistant packaging, while cellophane remains popular for its biodegradability and clarity. Both bioplastics serve complementary roles, balancing environmental benefits with functional properties in sustainable packaging solutions.

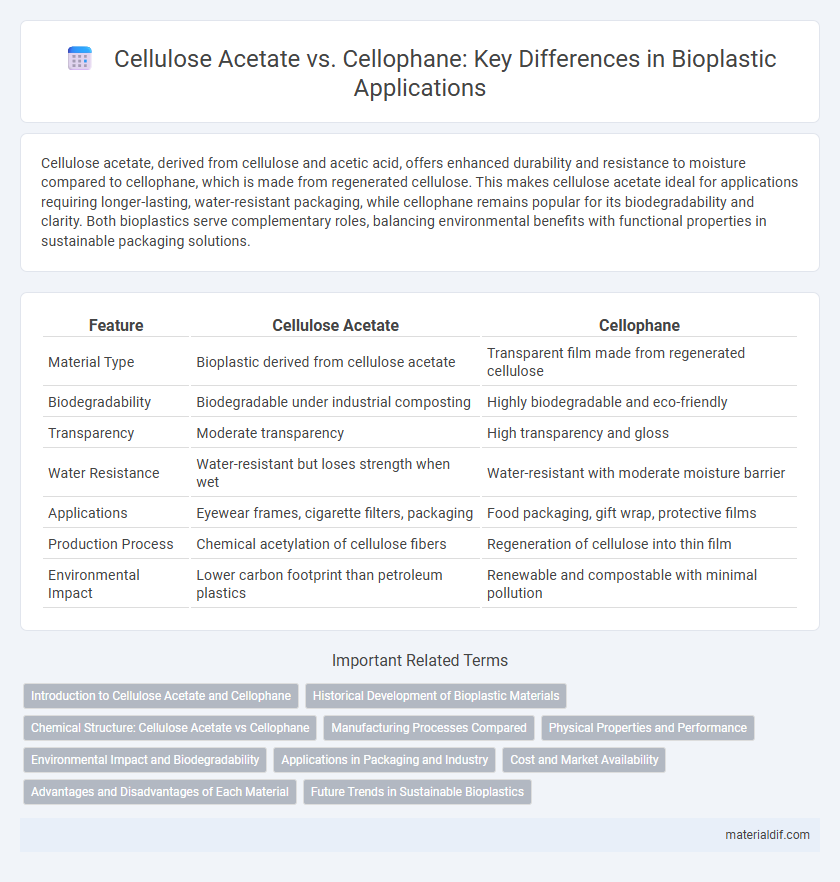

Table of Comparison

| Feature | Cellulose Acetate | Cellophane |

|---|---|---|

| Material Type | Bioplastic derived from cellulose acetate | Transparent film made from regenerated cellulose |

| Biodegradability | Biodegradable under industrial composting | Highly biodegradable and eco-friendly |

| Transparency | Moderate transparency | High transparency and gloss |

| Water Resistance | Water-resistant but loses strength when wet | Water-resistant with moderate moisture barrier |

| Applications | Eyewear frames, cigarette filters, packaging | Food packaging, gift wrap, protective films |

| Production Process | Chemical acetylation of cellulose fibers | Regeneration of cellulose into thin film |

| Environmental Impact | Lower carbon footprint than petroleum plastics | Renewable and compostable with minimal pollution |

Introduction to Cellulose Acetate and Cellophane

Cellulose acetate, a bioplastic derived from cellulose through acetylation, offers enhanced durability, transparency, and resistance to moisture compared to cellophane, which is a regenerated cellulose film commonly used for packaging. Both materials originate from natural cellulose but differ significantly in chemical treatment and properties, with cellulose acetate exhibiting improved thermal stability and biodegradability. These characteristics make cellulose acetate a preferred choice in applications requiring strength and clarity while maintaining environmental sustainability.

Historical Development of Bioplastic Materials

Cellulose acetate, developed in the early 20th century, marked a significant advancement in bioplastic materials due to its enhanced durability and ease of processing compared to natural cellulose derivatives. In contrast, cellophane, invented in 1912 by Swiss chemist Jacques Brandenberger, served as one of the first commercially successful biodegradable films derived from cellulose. Both materials laid foundational roles in the evolution of bioplastics, driving innovation in sustainable packaging and reducing reliance on petroleum-based plastics.

Chemical Structure: Cellulose Acetate vs Cellophane

Cellulose acetate is a semi-synthetic polymer derived from cellulose through acetylation, where hydroxyl groups are replaced by acetate groups, resulting in increased hydrophobicity and durability. Cellophane, on the other hand, is regenerated cellulose made by dissolving cellulose pulp and re-solidifying it into thin films, preserving hydroxyl groups that contribute to its biodegradability and moisture sensitivity. Differences in chemical structure between cellulose acetate and cellophane influence their mechanical properties, water resistance, and applications in biodegradable packaging.

Manufacturing Processes Compared

Cellulose acetate is produced through the acetylation of cellulose treated with acetic anhydride, requiring a controlled chemical reaction and solvent evaporation process to form films or fibers. Cellophane, on the other hand, is manufactured by regenerating purified cellulose in a viscose solution, followed by extrusion and regeneration into thin, transparent films. The manufacturing of cellulose acetate involves esterification and plasticization steps, while cellophane's process centers on cellulose dissolution, shaping, and regeneration without chemical modification.

Physical Properties and Performance

Cellulose acetate exhibits higher tensile strength and better chemical resistance compared to cellophane, making it more suitable for durable packaging applications. Its lower moisture permeability enhances product preservation, while cellophane's superior clarity and flexibility favor flexible wrapping uses. Both materials biodegrade, but cellulose acetate offers improved dimensional stability and thermal resistance, extending its functional lifespan under various environmental conditions.

Environmental Impact and Biodegradability

Cellulose acetate and cellophane are both cellulose-based bioplastics with differing environmental impacts and biodegradability profiles. Cellulose acetate, often plasticized and more chemically modified, exhibits slower biodegradation and can contribute to microplastic pollution if not disposed of properly. Cellophane, composed of regenerated cellulose, is more readily biodegradable and environmentally friendly, breaking down more completely under natural conditions without releasing harmful residues.

Applications in Packaging and Industry

Cellulose acetate is widely used in packaging due to its excellent film-forming properties, transparency, and biodegradability, making it ideal for food wrappers and cigarette filters. Cellophane, derived from regenerated cellulose, excels in moisture resistance and breathability, making it popular for wrapping perishable goods and gift packaging. Both materials contribute to sustainable packaging solutions but differ in their chemical properties and industrial applications, with cellulose acetate often favored for durability and cellophane for barrier performance.

Cost and Market Availability

Cellulose acetate is generally more expensive than cellophane due to its complex manufacturing process and higher purity standards, which limits its market availability primarily to specialized applications. Cellophane, made from regenerated cellulose, is cost-effective and widely available, dominating packaging markets with its biodegradability and clarity. Both materials are used as sustainable alternatives to traditional plastics, but cost efficiency gives cellophane a broader commercial reach.

Advantages and Disadvantages of Each Material

Cellulose acetate offers superior moisture resistance and durability compared to cellophane, making it ideal for packaging that requires enhanced protection and longer shelf life. Cellophane, being biodegradable and highly transparent, excels in eco-friendly applications but is less resistant to water and mechanical stress. While cellulose acetate provides better strength and flexibility, cellophane remains a cost-effective and sustainable option, though it may degrade faster under humid conditions.

Future Trends in Sustainable Bioplastics

Cellulose acetate and cellophane, both derived from cellulose, are key materials in the evolving market of sustainable bioplastics, with cellulose acetate offering enhanced biodegradability and thermal stability compared to traditional cellophane. Future trends emphasize increased research in cellulose acetate's compatibility with composting systems and its potential for use in biodegradable packaging applications, providing a promising alternative to conventional plastics. Innovations in processing techniques and molecular modifications aim to optimize cellulose acetate's properties, further driving its adoption in eco-friendly and circular economy solutions.

Cellulose acetate vs Cellophane Infographic

materialdif.com

materialdif.com