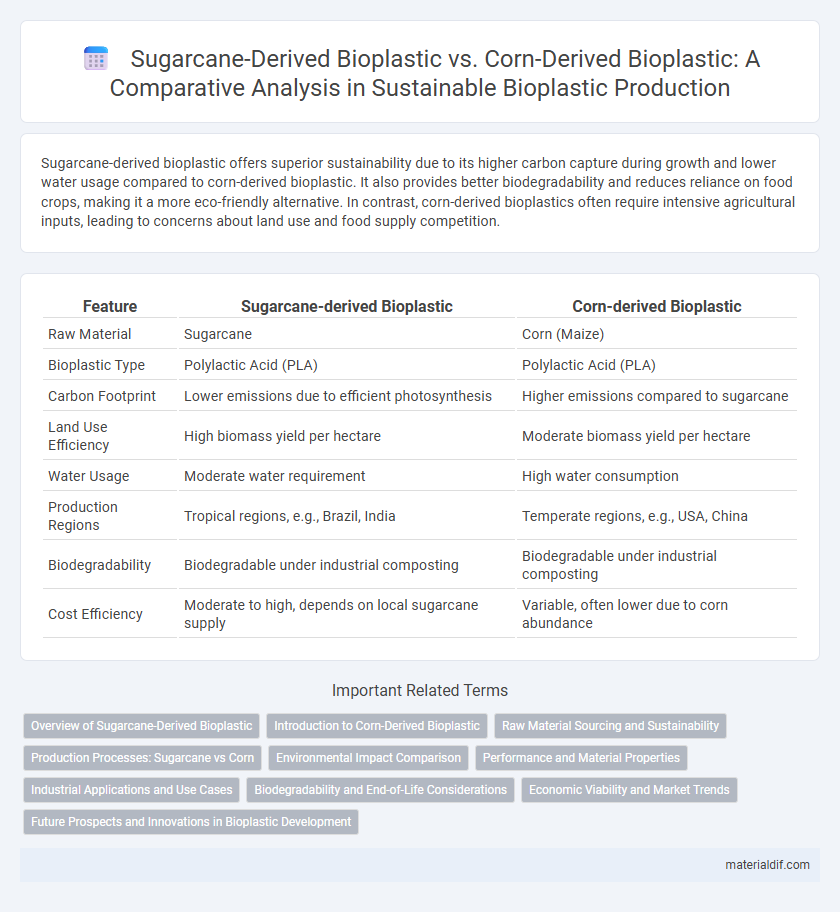

Sugarcane-derived bioplastic offers superior sustainability due to its higher carbon capture during growth and lower water usage compared to corn-derived bioplastic. It also provides better biodegradability and reduces reliance on food crops, making it a more eco-friendly alternative. In contrast, corn-derived bioplastics often require intensive agricultural inputs, leading to concerns about land use and food supply competition.

Table of Comparison

| Feature | Sugarcane-derived Bioplastic | Corn-derived Bioplastic |

|---|---|---|

| Raw Material | Sugarcane | Corn (Maize) |

| Bioplastic Type | Polylactic Acid (PLA) | Polylactic Acid (PLA) |

| Carbon Footprint | Lower emissions due to efficient photosynthesis | Higher emissions compared to sugarcane |

| Land Use Efficiency | High biomass yield per hectare | Moderate biomass yield per hectare |

| Water Usage | Moderate water requirement | High water consumption |

| Production Regions | Tropical regions, e.g., Brazil, India | Temperate regions, e.g., USA, China |

| Biodegradability | Biodegradable under industrial composting | Biodegradable under industrial composting |

| Cost Efficiency | Moderate to high, depends on local sugarcane supply | Variable, often lower due to corn abundance |

Overview of Sugarcane-Derived Bioplastic

Sugarcane-derived bioplastic is produced through the fermentation of sugarcane juice or molasses, resulting in polyhydroxyalkanoates (PHAs) or polylactic acid (PLA) that are biodegradable and renewable. This bioplastic offers a lower carbon footprint compared to conventional plastics, with sugarcane cultivation capturing significant amounts of CO2 during growth. The feedstock's high yield per hectare and efficient fermentation process make sugarcane a competitive and sustainable source for bioplastic production compared to corn-based alternatives.

Introduction to Corn-Derived Bioplastic

Corn-derived bioplastic, primarily made from polylactic acid (PLA), offers a renewable alternative to petroleum-based plastics by utilizing fermentable sugars from corn starch. This bioplastic features biodegradability and compostability, making it suitable for packaging, agricultural films, and disposable items. Compared to sugarcane-derived bioplastics, corn-based variants often have faster production cycles but may compete with food supply chains and require more intensive agricultural inputs.

Raw Material Sourcing and Sustainability

Sugarcane-derived bioplastic boasts a higher photosynthetic efficiency, enabling greater biomass yield per hectare compared to corn, which translates to more sustainable raw material sourcing. Sugarcane cultivation generally requires less irrigation and fewer pesticides, reducing environmental impact while enhancing carbon sequestration potential in bioplastic production. Corn-derived bioplastic, although widely used, often involves intensive agricultural inputs and competes with food crops, posing significant sustainability challenges.

Production Processes: Sugarcane vs Corn

Sugarcane-derived bioplastic production involves the fermentation of sucrose-rich juice to yield bioethanol, which is then polymerized into bioplastics like polylactic acid (PLA) or bio-based polyethylene. Corn-derived bioplastic production primarily relies on starch extraction followed by enzymatic hydrolysis to convert starch into glucose, which is fermented into lactic acid or other monomers for bioplastic synthesis. Sugarcane processes are generally more energy-efficient and produce higher biomass yields per hectare, while corn-based methods are well-established but often require more intensive land and resource inputs.

Environmental Impact Comparison

Sugarcane-derived bioplastic typically demonstrates a lower carbon footprint compared to corn-derived bioplastic due to its higher photosynthetic efficiency and greater biomass yield per hectare. The cultivation of sugarcane requires less synthetic fertilizer and pesticide input, reducing soil degradation and water contamination relative to intensive corn farming practices. Furthermore, sugarcane bioplastics benefit from using bagasse, a byproduct that minimizes waste, whereas corn bioplastics rely heavily on starch extraction, which increases energy consumption and competes with food resources.

Performance and Material Properties

Sugarcane-derived bioplastic exhibits superior mechanical strength and UV resistance compared to corn-derived bioplastic, making it ideal for packaging applications requiring durability. Its higher crystallinity and lower water absorption contribute to enhanced barrier properties against moisture and gases. Corn-derived bioplastic typically offers better biodegradability rates but lower thermal stability and tensile strength, limiting its use in high-performance environments.

Industrial Applications and Use Cases

Sugarcane-derived bioplastics offer superior mechanical strength and moisture resistance, making them ideal for packaging in the food and beverage industry, as well as durable goods manufacturing. Corn-derived bioplastics, commonly based on polylactic acid (PLA), are widely used in disposable items such as cutlery, food containers, and agricultural films due to their compostability and lower production costs. In industrial applications, sugarcane bioplastics are favored for automotive parts and electronic casings, where durability and heat resistance are critical.

Biodegradability and End-of-Life Considerations

Sugarcane-derived bioplastic typically offers enhanced biodegradability in natural environments due to its higher cellulose content, facilitating faster microbial breakdown compared to corn-derived bioplastic. End-of-life considerations favor sugarcane bioplastics as they often decompose efficiently in industrial composting facilities, reducing landfill accumulation and greenhouse gas emissions. In contrast, corn-derived bioplastics may require specific composting conditions to achieve similar biodegradation rates, posing challenges in waste management infrastructure compatibility.

Economic Viability and Market Trends

Sugarcane-derived bioplastic shows higher economic viability due to its lower production costs and greater yield per hectare compared to corn-derived bioplastic, which requires more intensive agricultural inputs. Market trends reveal increasing demand for sugarcane bioplastics driven by consumer preference for sustainable products and supportive policies in tropical regions. Corn-derived bioplastics face challenges from food supply concerns and fluctuating prices, limiting their market expansion in comparison.

Future Prospects and Innovations in Bioplastic Development

Sugarcane-derived bioplastics exhibit promising future prospects due to higher biomass yield and carbon sequestration efficiency, fostering sustainable production and reducing reliance on fossil fuels. Innovations such as enhanced enzymatic hydrolysis and genetic modification techniques are improving the fermentation process, increasing biopolymer yield and mechanical properties. Compared to corn-derived bioplastics, sugarcane-based alternatives demonstrate greater potential for scalability and lower environmental impact, driving ongoing research towards next-generation biodegradable materials.

Sugarcane-derived Bioplastic vs Corn-derived Bioplastic Infographic

materialdif.com

materialdif.com