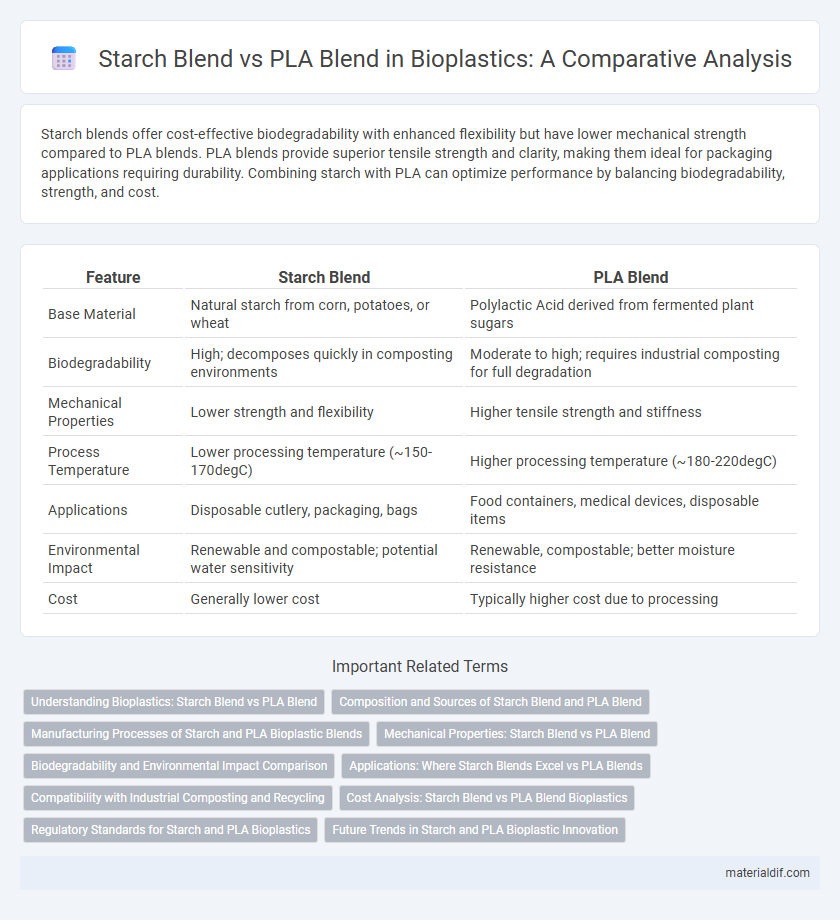

Starch blends offer cost-effective biodegradability with enhanced flexibility but have lower mechanical strength compared to PLA blends. PLA blends provide superior tensile strength and clarity, making them ideal for packaging applications requiring durability. Combining starch with PLA can optimize performance by balancing biodegradability, strength, and cost.

Table of Comparison

| Feature | Starch Blend | PLA Blend |

|---|---|---|

| Base Material | Natural starch from corn, potatoes, or wheat | Polylactic Acid derived from fermented plant sugars |

| Biodegradability | High; decomposes quickly in composting environments | Moderate to high; requires industrial composting for full degradation |

| Mechanical Properties | Lower strength and flexibility | Higher tensile strength and stiffness |

| Process Temperature | Lower processing temperature (~150-170degC) | Higher processing temperature (~180-220degC) |

| Applications | Disposable cutlery, packaging, bags | Food containers, medical devices, disposable items |

| Environmental Impact | Renewable and compostable; potential water sensitivity | Renewable, compostable; better moisture resistance |

| Cost | Generally lower cost | Typically higher cost due to processing |

Understanding Bioplastics: Starch Blend vs PLA Blend

Starch blends combine natural starch with biodegradable polymers, offering cost-effective, compostable packaging solutions but with limited mechanical strength and moisture resistance. PLA blends, derived from renewable resources like corn starch, provide higher tensile strength and clarity, making them ideal for food packaging and medical applications. The choice between starch and PLA blends depends on the desired balance of biodegradability, durability, and application-specific performance.

Composition and Sources of Starch Blend and PLA Blend

Starch blends primarily consist of natural starches derived from corn, potato, or tapioca, combined with biodegradable polymers to enhance flexibility and mechanical properties. PLA blends are composed of polylactic acid, a biopolymer produced through the fermentation of renewable resources such as corn starch, sugarcane, or cassava. Both blends leverage renewable biomass, but starch blends rely more heavily on native polysaccharides, while PLA blends focus on synthesized lactic acid polymers for biodegradability and strength.

Manufacturing Processes of Starch and PLA Bioplastic Blends

Starch blend bioplastics involve gelatinization and retrogradation processes where starch granules are heated with plasticizers to form a thermoplastic material, often requiring extrusion or injection molding techniques. PLA blend manufacturing typically includes melt blending PLA pellets with additives or other biopolymers using processes like twin-screw extrusion to achieve homogenous material properties. Both blends demand precise control over temperature and moisture to optimize mechanical strength and biodegradability during processing.

Mechanical Properties: Starch Blend vs PLA Blend

Starch blend bioplastics typically exhibit lower tensile strength and flexibility compared to PLA blends, which possess superior mechanical properties such as higher elasticity and durability. PLA blends offer enhanced impact resistance and stiffness, making them more suitable for applications requiring structural integrity. The molecular structure of PLA contributes to its greater mechanical stability, whereas starch blends often require additives to improve performance characteristics.

Biodegradability and Environmental Impact Comparison

Starch blends biodegrade more rapidly than PLA blends due to their natural polysaccharide structure, enabling faster microbial decomposition in soil and compost environments. PLA blends, while compostable under industrial conditions, degrade slowly in natural settings, leading to longer environmental persistence. Starch-based bioplastics exhibit lower carbon footprints and reduced environmental impact as they derive from renewable crops and break down more efficiently without releasing harmful residues.

Applications: Where Starch Blends Excel vs PLA Blends

Starch blends excel in packaging applications due to their excellent biodegradability and cost-effectiveness, making them ideal for single-use items such as food containers and disposable bags. PLA blends, with superior mechanical strength and clarity, are preferred in medical devices and durable consumer goods where performance and aesthetics are critical. Both materials offer sustainable solutions but suit different application demands based on their distinct properties.

Compatibility with Industrial Composting and Recycling

Starch blends typically offer higher compatibility with industrial composting due to their faster biodegradation rates under controlled conditions, breaking down within weeks to months. PLA blends, while compostable, require more specific industrial composting environments with higher temperatures and longer retention times to effectively degrade. Both materials present challenges in conventional recycling streams, but starch blends are generally more favorable for composting rather than mechanical recycling, whereas PLA blends may contaminate PET recycling if not properly segregated.

Cost Analysis: Starch Blend vs PLA Blend Bioplastics

Starch blend bioplastics typically offer lower raw material costs compared to PLA blends due to the abundant availability of starch from crops like corn and potatoes. Manufacturing expenses for starch blends are generally reduced since they require less energy-intensive processing than PLA, which is derived from fermentable sugars through polymerization. However, the overall cost-effectiveness must consider factors such as durability and application-specific performance, where PLA blends might justify higher expenses with superior mechanical properties and biodegradability.

Regulatory Standards for Starch and PLA Bioplastics

Starch blend bioplastics comply with regulatory standards such as FDA 21 CFR 177.1520 for food contact materials and European Union Regulation (EU) No 10/2011, ensuring safe biodegradability and non-toxicity. PLA blends meet stringent certifications including ASTM D6400 for compostability and EN 13432, which govern industrial composting and environmental impact. Both starch and PLA bioplastics require adherence to REACH and RoHS directives to limit hazardous substances and promote sustainability in packaging and product applications.

Future Trends in Starch and PLA Bioplastic Innovation

Future trends in starch and PLA bioplastic innovation emphasize enhancing material performance through advanced blending technologies that improve mechanical strength and biodegradability. Research focuses on optimizing compatibilizers and plasticizers to create starch-PLA blends with superior thermal stability and moisture resistance suitable for packaging and agricultural applications. Integration of bio-based additives and nanomaterials is driving the development of next-generation bioplastics with tailored properties for sustainable industry adoption.

Starch blend vs PLA blend Infographic

materialdif.com

materialdif.com