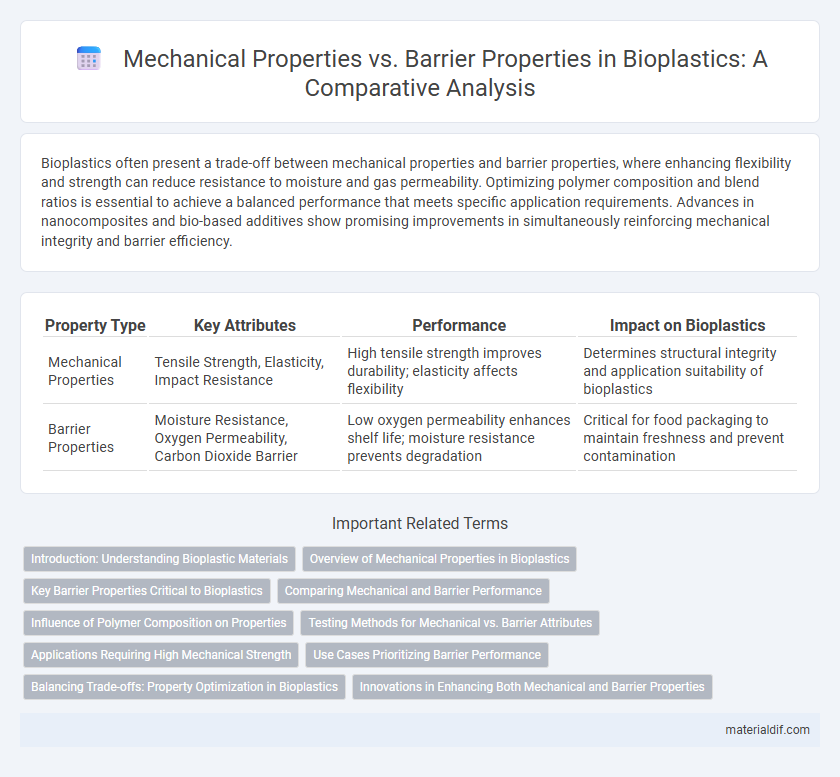

Bioplastics often present a trade-off between mechanical properties and barrier properties, where enhancing flexibility and strength can reduce resistance to moisture and gas permeability. Optimizing polymer composition and blend ratios is essential to achieve a balanced performance that meets specific application requirements. Advances in nanocomposites and bio-based additives show promising improvements in simultaneously reinforcing mechanical integrity and barrier efficiency.

Table of Comparison

| Property Type | Key Attributes | Performance | Impact on Bioplastics |

|---|---|---|---|

| Mechanical Properties | Tensile Strength, Elasticity, Impact Resistance | High tensile strength improves durability; elasticity affects flexibility | Determines structural integrity and application suitability of bioplastics |

| Barrier Properties | Moisture Resistance, Oxygen Permeability, Carbon Dioxide Barrier | Low oxygen permeability enhances shelf life; moisture resistance prevents degradation | Critical for food packaging to maintain freshness and prevent contamination |

Introduction: Understanding Bioplastic Materials

Bioplastic materials exhibit a complex balance between mechanical properties such as tensile strength and flexibility, and barrier properties including moisture and gas permeability. These characteristics are crucial for determining the suitability of bioplastics in packaging, medical devices, and other applications requiring durability and protection. Enhancing mechanical performance often affects barrier efficiency, necessitating innovative formulations to optimize both attributes for specific industrial needs.

Overview of Mechanical Properties in Bioplastics

Bioplastics exhibit diverse mechanical properties such as tensile strength, elasticity, and impact resistance, which vary significantly depending on their polymer composition like polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based materials. These mechanical attributes influence the material's suitability for applications requiring durability, flexibility, or rigidity, with PLA offering high stiffness but low impact resistance compared to more flexible PHA variants. Understanding the balance between mechanical properties and barrier properties is crucial for designing bioplastics that meet specific performance criteria in packaging, agriculture, and biomedical fields.

Key Barrier Properties Critical to Bioplastics

Key barrier properties critical to bioplastics include oxygen permeability, water vapor transmission rate, and carbon dioxide permeability, which directly impact shelf life and product preservation. Mechanical properties such as tensile strength, elongation at break, and modulus of elasticity influence the durability and flexibility of bioplastic materials but must be balanced with barrier performance to meet packaging requirements. Optimizing these barrier properties ensures effective protection against moisture, gases, and contaminants, making bioplastics viable alternatives to conventional plastics in food and pharmaceutical packaging.

Comparing Mechanical and Barrier Performance

Mechanical properties of bioplastics such as tensile strength, elasticity, and impact resistance determine their durability and structural integrity in various applications. Barrier properties, including permeability to gases like oxygen and moisture, are critical for packaging performance and shelf-life extension. Comparing these aspects reveals that optimizing bioplastic formulations often requires balancing mechanical strength with effective barrier functionality to meet specific industrial and environmental demands.

Influence of Polymer Composition on Properties

Polymer composition plays a crucial role in determining the mechanical and barrier properties of bioplastics, where incorporating crystalline structures such as polylactic acid (PLA) enhances tensile strength but may reduce flexibility. The addition of copolymers like polyhydroxyalkanoates (PHAs) can improve barrier resistance to gases and moisture, optimizing performance for packaging applications. Tailoring the ratio and molecular weight of polymer blends directly influences the balance between durability and permeability, enabling customization for specific industrial needs.

Testing Methods for Mechanical vs. Barrier Attributes

Mechanical properties of bioplastics are evaluated through testing methods such as tensile strength, elongation at break, and impact resistance using universal testing machines, providing insights into flexibility, toughness, and durability. Barrier properties, crucial for packaging applications, are assessed by measuring water vapor transmission rate (WVTR) and oxygen permeability using specialized equipment like MOCON analyzers and coulometric sensors. Understanding these test results enables optimization of bioplastic formulations for both mechanical resilience and effective moisture and gas barrier performance.

Applications Requiring High Mechanical Strength

Bioplastics with high mechanical strength, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are ideal for applications like packaging and automotive parts that demand durability and impact resistance. These materials exhibit superior tensile strength and flexibility, ensuring structural integrity under stress while maintaining biodegradability. However, optimizing barrier properties such as moisture and oxygen resistance is crucial to extend shelf life in food packaging without compromising mechanical performance.

Use Cases Prioritizing Barrier Performance

Bioplastics with enhanced barrier properties excel in packaging applications requiring protection against moisture, oxygen, and contaminants to extend product shelf life, such as food and pharmaceutical packaging. While mechanical properties ensure durability and structural integrity, prioritizing barrier performance is crucial for perishable goods that demand airtight and moisture-resistant packaging solutions. Innovations like polyhydroxyalkanoates (PHA) and polylactic acid (PLA) blends improve barrier effectiveness, balancing sustainability with functional performance for sensitive product preservation.

Balancing Trade-offs: Property Optimization in Bioplastics

Mechanical properties such as tensile strength and elasticity often conflict with barrier properties like moisture and gas permeability in bioplastics, requiring a specialized approach to balance these trade-offs. Enhancing crystallinity or incorporating nanofillers can improve barrier performance but may reduce flexibility or impact resistance, demanding precise formulation strategies. Optimizing additive dispersion and polymer blending enables tailored bioplastic materials that meet specific application requirements without compromising critical functional properties.

Innovations in Enhancing Both Mechanical and Barrier Properties

Innovations in bioplastic technology have led to the development of novel composites that significantly enhance both mechanical strength and barrier properties, such as nanoclay and cellulose nanocrystals incorporation. These advanced materials exhibit improved tensile strength and elongation while providing superior resistance to oxygen and moisture permeability, essential for food packaging applications. Recent breakthroughs in crosslinking agents and bio-based additives further optimize the balance between durability and barrier efficiency, driving sustainable alternatives in packaging industries.

Mechanical properties vs Barrier properties Infographic

materialdif.com

materialdif.com