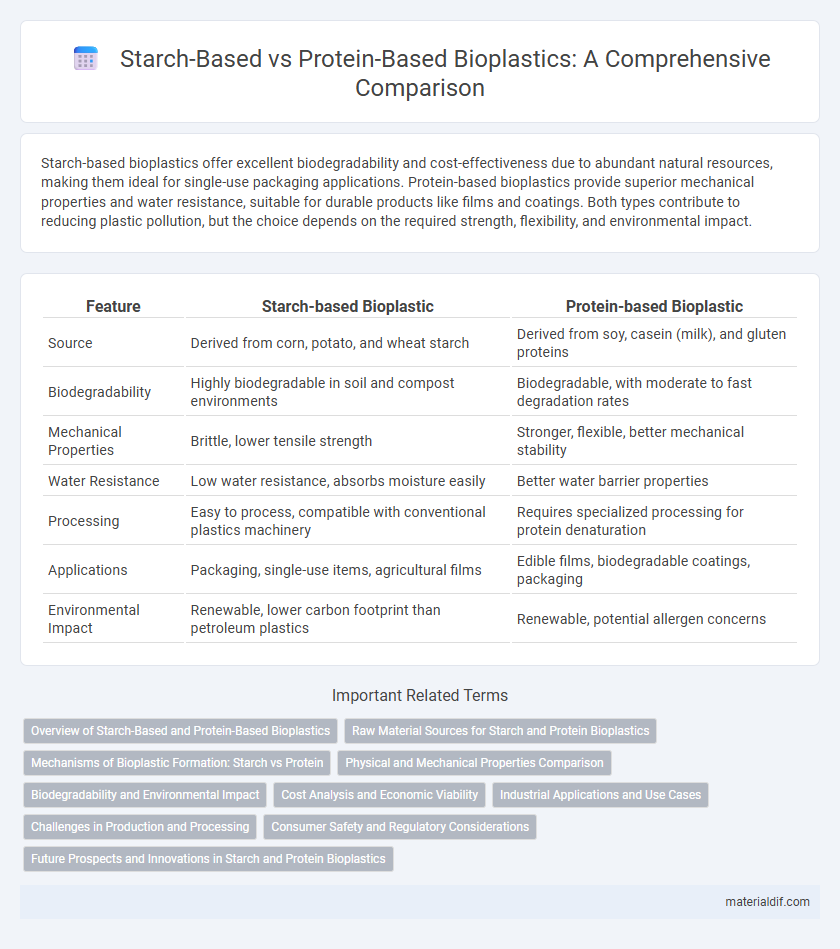

Starch-based bioplastics offer excellent biodegradability and cost-effectiveness due to abundant natural resources, making them ideal for single-use packaging applications. Protein-based bioplastics provide superior mechanical properties and water resistance, suitable for durable products like films and coatings. Both types contribute to reducing plastic pollution, but the choice depends on the required strength, flexibility, and environmental impact.

Table of Comparison

| Feature | Starch-based Bioplastic | Protein-based Bioplastic |

|---|---|---|

| Source | Derived from corn, potato, and wheat starch | Derived from soy, casein (milk), and gluten proteins |

| Biodegradability | Highly biodegradable in soil and compost environments | Biodegradable, with moderate to fast degradation rates |

| Mechanical Properties | Brittle, lower tensile strength | Stronger, flexible, better mechanical stability |

| Water Resistance | Low water resistance, absorbs moisture easily | Better water barrier properties |

| Processing | Easy to process, compatible with conventional plastics machinery | Requires specialized processing for protein denaturation |

| Applications | Packaging, single-use items, agricultural films | Edible films, biodegradable coatings, packaging |

| Environmental Impact | Renewable, lower carbon footprint than petroleum plastics | Renewable, potential allergen concerns |

Overview of Starch-Based and Protein-Based Bioplastics

Starch-based bioplastics are primarily derived from corn, potato, and wheat starch, offering biodegradability and low cost, but limited mechanical strength and water resistance. Protein-based bioplastics utilize sources like soy, whey, and casein proteins, providing better barrier properties and elasticity compared to starch-based plastics. Both types are renewable alternatives to petroleum-based plastics, with starch-based bioplastics favored for packaging applications and protein-based bioplastics suited for edible films and coatings.

Raw Material Sources for Starch and Protein Bioplastics

Starch-based bioplastics primarily derive from abundant crops such as corn, potatoes, and wheat, offering a renewable and cost-effective source of raw materials rich in amylose and amylopectin. Protein-based bioplastics utilize raw materials like soy, whey, and gluten, capitalizing on their high amino acid content to form durable polymer networks. The choice of raw materials significantly influences the biodegradability, mechanical properties, and application scope of each bioplastic type.

Mechanisms of Bioplastic Formation: Starch vs Protein

Starch-based bioplastics form through gelatinization, where heat and water disrupt starch granules, enabling polymer chains to rearrange and bond upon cooling, creating a stable matrix. Protein-based bioplastics rely on protein denaturation and subsequent cross-linking of amino acid chains, which creates a resilient network with enhanced mechanical properties. The molecular interactions differ: starch primarily involves hydrogen bonding of polysaccharide chains, while proteins form complex three-dimensional structures via covalent and non-covalent bonds.

Physical and Mechanical Properties Comparison

Starch-based bioplastics typically exhibit lower tensile strength and flexibility but have excellent biodegradability due to their hydrophilic nature. Protein-based bioplastics offer superior mechanical properties such as higher elasticity, tensile strength, and oxygen barrier capabilities, making them suitable for food packaging applications. Both types show different moisture sensitivities, with starch-based variants being more prone to water absorption, affecting dimensional stability and mechanical performance.

Biodegradability and Environmental Impact

Starch-based bioplastics exhibit high biodegradability due to their natural polysaccharide composition, breaking down efficiently in soil and compost environments. Protein-based bioplastics, derived from soy or whey proteins, offer similar biodegradability but may require specific enzymatic conditions to decompose fully, potentially extending degradation time. Both types significantly reduce environmental impact compared to petroleum-based plastics, with starch-based variants typically exhibiting lower greenhouse gas emissions during production and degradation.

Cost Analysis and Economic Viability

Starch-based bioplastics generally offer lower production costs due to abundant raw materials like corn or potato starch, making them economically viable for large-scale applications. Protein-based bioplastics, derived from sources such as soy or whey, tend to have higher costs linked to complex extraction and processing methods, limiting their market penetration. Cost-effectiveness of starch-based bioplastics supports widespread commercialization, while protein-based variants require technological advancements to improve their economic feasibility.

Industrial Applications and Use Cases

Starch-based bioplastics are widely used in packaging, agricultural films, and disposable tableware due to their biodegradability and cost-effectiveness. Protein-based bioplastics find niche applications in medical implants, drug delivery systems, and food packaging where enhanced mechanical strength and barrier properties are critical. Industrial use of starch-based bioplastics is predominant in consumer goods, while protein-based bioplastics cater to specialized sectors requiring biocompatibility and durability.

Challenges in Production and Processing

Starch-based bioplastics face challenges such as high moisture sensitivity and limited mechanical strength, requiring plasticizers and blending agents to improve performance. Protein-based bioplastics encounter difficulties in processing due to their complex molecular structure, which can cause poor thermal stability and scalability issues. Both types demand advanced techniques to enhance compatibility with conventional manufacturing processes while maintaining biodegradability.

Consumer Safety and Regulatory Considerations

Starch-based bioplastics, primarily composed of polysaccharides, generally exhibit lower allergenic risks and are widely accepted under food contact regulations such as FDA and EFSA standards. Protein-based bioplastics, derived from sources like soy or casein, require stringent assessment for allergenicity and potential protein residue migration, influencing compliance with consumer safety guidelines. Regulatory frameworks prioritize material composition transparency and biodegradability certifications to ensure safe commercialization and consumer protection in both bioplastic types.

Future Prospects and Innovations in Starch and Protein Bioplastics

Starch-based bioplastics are advancing through innovations in blending with biodegradable polymers and nanomaterials, enhancing mechanical strength and water resistance, which boosts their applications in packaging and agriculture. Protein-based bioplastics benefit from bioengineering techniques that improve film-forming properties and biodegradability while tailoring functional characteristics for medical and food industries. Future prospects include hybrid composites combining starch and protein polymers to optimize performance, reduce carbon footprint, and expand sustainable material use in various industrial sectors.

Starch-based bioplastic vs Protein-based bioplastic Infographic

materialdif.com

materialdif.com