Mater-Bi and BioPBSA are two prominent bioplastics derived from renewable resources, offering biodegradable alternatives to traditional plastics. Mater-Bi is known for its excellent compostability and is primarily made from starch-based materials, making it suitable for packaging and agricultural films. BioPBSA is a copolymer of bio-based polybutylene succinate and adipate, providing enhanced flexibility and durability for applications such as flexible packaging and biodegradable bags.

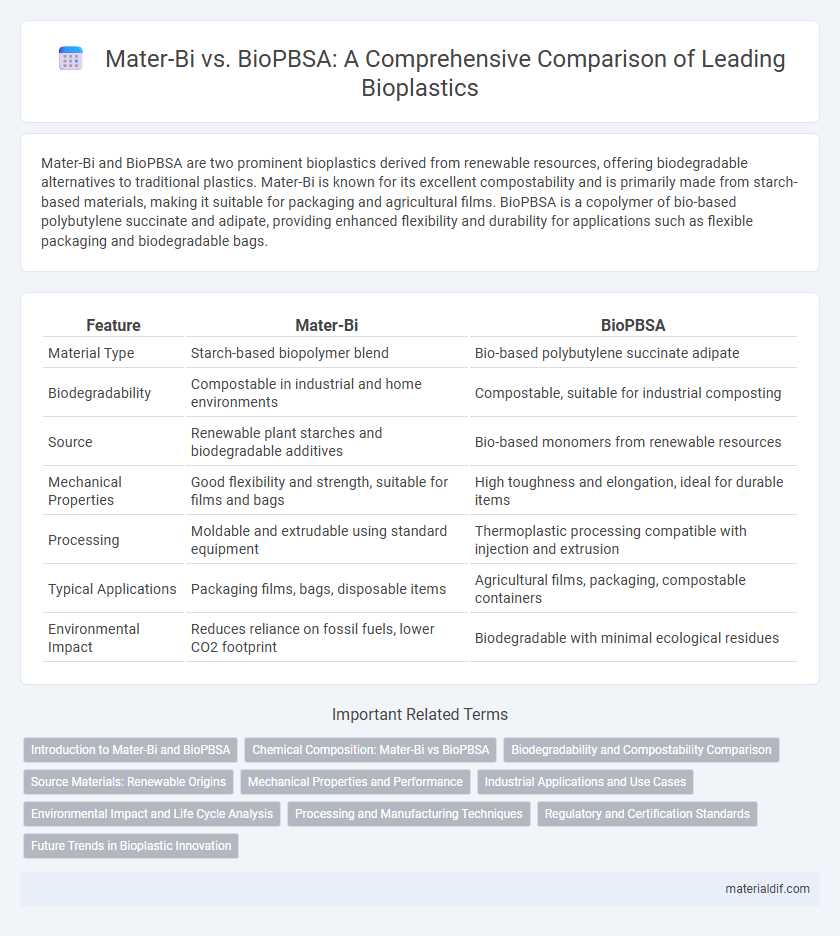

Table of Comparison

| Feature | Mater-Bi | BioPBSA |

|---|---|---|

| Material Type | Starch-based biopolymer blend | Bio-based polybutylene succinate adipate |

| Biodegradability | Compostable in industrial and home environments | Compostable, suitable for industrial composting |

| Source | Renewable plant starches and biodegradable additives | Bio-based monomers from renewable resources |

| Mechanical Properties | Good flexibility and strength, suitable for films and bags | High toughness and elongation, ideal for durable items |

| Processing | Moldable and extrudable using standard equipment | Thermoplastic processing compatible with injection and extrusion |

| Typical Applications | Packaging films, bags, disposable items | Agricultural films, packaging, compostable containers |

| Environmental Impact | Reduces reliance on fossil fuels, lower CO2 footprint | Biodegradable with minimal ecological residues |

Introduction to Mater-Bi and BioPBSA

Mater-Bi is a family of biodegradable bioplastics derived primarily from corn starch, often combined with biodegradable polyesters to enhance its mechanical properties and compostability. BioPBSA is a bio-based copolyester synthesized from succinic acid and 1,4-butanediol, known for its flexibility, thermal resistance, and biodegradability. Both Mater-Bi and BioPBSA are designed to replace conventional plastics in packaging, agriculture, and consumer products, offering sustainable alternatives with distinct chemical compositions and performance characteristics.

Chemical Composition: Mater-Bi vs BioPBSA

Mater-Bi is a biodegradable bioplastic primarily derived from starch, polybutylene adipate terephthalate (PBAT), and other biodegradable polymers, offering flexibility and compostability. BioPBSA consists mainly of polybutylene succinate adipate (PBSA), a fully biodegradable aliphatic polyester known for better thermal resistance and mechanical strength compared to pure starch-based materials. The chemical composition difference results in Mater-Bi being more suited for applications requiring high biodegradability, while BioPBSA excels in durability and processability.

Biodegradability and Compostability Comparison

Mater-Bi and BioPBSA both offer excellent biodegradability, with Mater-Bi composed of starch-based polymers that typically degrade within 90 to 180 days under industrial composting conditions. BioPBSA, a blend of polybutylene succinate (PBS) and polybutylene adipate-co-terephthalate (PBAT), demonstrates rapid biodegradation and complete compostability in about 60 to 120 days, meeting ASTM D6400 and EN 13432 standards. The rate of biodegradability in BioPBSA is generally faster due to its synthetic polyester components, while Mater-Bi's natural-origin matrix enhances soil integration during composting.

Source Materials: Renewable Origins

Mater-Bi is primarily derived from renewable starches such as corn and tapioca, emphasizing biodegradable thermoplastic compositions from natural biomass. BioPBSA combines biodegradable polybutylene succinate (PBS) and adipate sourced from renewable feedstocks like plant sugars and oils, optimizing its eco-friendly profile. Both materials leverage renewable agricultural resources, but Mater-Bi's starch base contrasts with BioPBSA's polyester blend for tailored biodegradability.

Mechanical Properties and Performance

Mater-Bi exhibits superior tensile strength and elongation at break compared to BioPBSA, making it more suitable for applications requiring durability and flexibility. BioPBSA offers enhanced impact resistance and better biodegradability rates under industrial composting conditions. The distinct performance profiles of Mater-Bi and BioPBSA influence their selection for packaging, agricultural films, and disposable products based on mechanical stress requirements.

Industrial Applications and Use Cases

Mater-Bi, a starch-based bioplastic, excels in compostable packaging and agricultural films due to its biodegradability and soil-friendly properties, making it ideal for single-use applications. BioPBSA, a copolymer of bio-based polybutylene succinate and adipate, offers superior mechanical strength and thermal resistance, suited for durable industrial parts and flexible packaging. Both materials support sustainability goals, with Mater-Bi preferred in short lifecycle products and BioPBSA favored for applications requiring resilience and extended use.

Environmental Impact and Life Cycle Analysis

Mater-Bi, a starch-based bioplastic, demonstrates lower greenhouse gas emissions and reduced fossil resource depletion compared to BioPBSA, which is a biodegradable copolyester derived from renewable resources. Life Cycle Analysis (LCA) highlights Mater-Bi's advantage in compostability and end-of-life biodegradation under industrial conditions, whereas BioPBSA offers improved mechanical properties but may require more energy-intensive production processes. Environmental impact assessments indicate Mater-Bi's superior performance in soil biodegradability and carbon footprint reduction, making it a preferable option for single-use packaging applications.

Processing and Manufacturing Techniques

Mater-Bi, a starch-based bioplastic, offers versatility in processing through standard extrusion, injection molding, and thermoforming techniques, allowing compatibility with existing manufacturing infrastructure. BioPBSA, a copolymer of polybutylene succinate and adipate, requires optimized temperature control and shear conditions during extrusion and injection molding to maintain its mechanical properties and biodegradability. Both materials support sustainable production, but Material-Bi's adaptability often results in lower processing energy compared to BioPBSA's more sensitive thermal requirements.

Regulatory and Certification Standards

Mater-Bi, developed by Novamont, complies with the European Standard EN 13432, ensuring industrial compostability and recognition under the EU's Biodegradable Products Institute. BioPBSA, a blend of polybutylene succinate and adipate, meets ASTM D6400 standards for compostability in the United States and also adheres to the ISO 17088 certification for biodegradable plastics. Both materials are subject to stringent regulatory frameworks that verify biodegradability, compostability, and environmental safety, facilitating their acceptance in global markets.

Future Trends in Bioplastic Innovation

Mater-Bi, a starch-based bioplastic developed by Novamont, emphasizes compostability and agricultural waste valorization, while BioPBSA, a PBSA-based biopolymer, offers enhanced flexibility and biodegradability for diverse applications. Future trends in bioplastic innovation focus on improving material performance, integrating bio-based feedstocks, and advancing circular economy strategies to reduce environmental impact. Research continues to prioritize scalability and cost-efficiency to enable widespread adoption of sustainable bioplastics like Mater-Bi and BioPBSA.

Mater-Bi vs BioPBSA Infographic

materialdif.com

materialdif.com