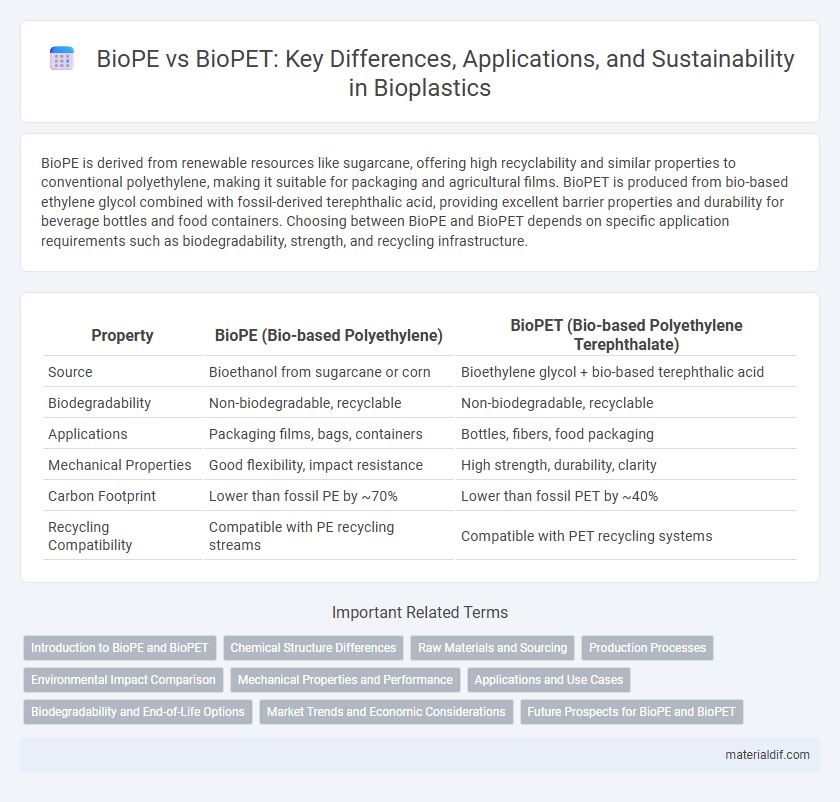

BioPE is derived from renewable resources like sugarcane, offering high recyclability and similar properties to conventional polyethylene, making it suitable for packaging and agricultural films. BioPET is produced from bio-based ethylene glycol combined with fossil-derived terephthalic acid, providing excellent barrier properties and durability for beverage bottles and food containers. Choosing between BioPE and BioPET depends on specific application requirements such as biodegradability, strength, and recycling infrastructure.

Table of Comparison

| Property | BioPE (Bio-based Polyethylene) | BioPET (Bio-based Polyethylene Terephthalate) |

|---|---|---|

| Source | Bioethanol from sugarcane or corn | Bioethylene glycol + bio-based terephthalic acid |

| Biodegradability | Non-biodegradable, recyclable | Non-biodegradable, recyclable |

| Applications | Packaging films, bags, containers | Bottles, fibers, food packaging |

| Mechanical Properties | Good flexibility, impact resistance | High strength, durability, clarity |

| Carbon Footprint | Lower than fossil PE by ~70% | Lower than fossil PET by ~40% |

| Recycling Compatibility | Compatible with PE recycling streams | Compatible with PET recycling systems |

Introduction to BioPE and BioPET

BioPE (biobased polyethylene) and BioPET (biobased polyethylene terephthalate) are two prominent bioplastics derived from renewable biomass sources such as sugarcane and corn. BioPE offers properties similar to conventional polyethylene, making it suitable for packaging, consumer goods, and agricultural films, while BioPET replicates the characteristics of traditional PET used extensively in beverage bottles and food containers. Both BioPE and BioPET contribute to reducing fossil fuel dependency and lowering greenhouse gas emissions in the plastics industry.

Chemical Structure Differences

BioPE (biopolyethylene) is a bio-based polymer derived from renewable ethylene sources, consisting of long chains of saturated hydrocarbons with a simple linear or branched structure. BioPET (bio-based polyethylene terephthalate) features a more complex aromatic polyester structure formed from terephthalic acid and ethylene glycol, contributing to its higher thermal stability and rigidity. The fundamental chemical difference lies in BioPE's non-polar hydrocarbon backbone versus BioPET's polar ester linkages and aromatic rings, influencing their respective mechanical properties and biodegradability.

Raw Materials and Sourcing

BioPE (biobased polyethylene) is primarily derived from renewable sugarcane feedstock, which offers a sustainable alternative by capturing atmospheric CO2 during growth. BioPET (biobased polyethylene terephthalate) combines plant-based monoethylene glycol, typically sourced from sugarcane or corn, with petrochemical-derived terephthalic acid, making it only partially biobased. The sourcing of BioPE emphasizes fully renewable raw materials, while BioPET relies on a hybrid approach that integrates both bio-based and fossil-derived components.

Production Processes

BioPE is produced through polymerization of bioethanol derived from sugarcane or corn, utilizing fermentation to convert biomass into ethylene monomers before polymerization. BioPET production involves bio-based terephthalic acid and monoethylene glycol, with bio-MEG commonly sourced from bioethanol, whereas bio-based PTA often still relies on fossil resources or advanced biomass conversion technologies. Both materials use distinct feedstocks and chemical pathways, with BioPE generally relying on simpler conversion of bioethanol to ethylene and BioPET requiring more complex synthesis of its two monomers for polymerization.

Environmental Impact Comparison

BioPE (bio-based polyethylene) offers a lower carbon footprint compared to BioPET (bio-based polyethylene terephthalate) due to its simpler production process and higher renewable content. BioPET, while derived from renewable resources like sugarcane, typically requires more energy-intensive processing, resulting in greater greenhouse gas emissions. Both bioplastics contribute to reduced fossil fuel dependence, but BioPE demonstrates superior environmental benefits in terms of lifecycle emissions and biodegradability potential.

Mechanical Properties and Performance

BioPE (biobased polyethylene) exhibits excellent impact resistance and flexibility, making it ideal for applications requiring durability and toughness, such as packaging films and containers. BioPET (biobased polyethylene terephthalate) offers superior tensile strength, stiffness, and thermal stability, which enhances performance in rigid containers, bottles, and fibers. BioPET's resistance to deformation and higher glass transition temperature allows for better dimensional stability compared to BioPE, which tends to be softer and more pliable under stress.

Applications and Use Cases

BioPE (bio-based polyethylene) is primarily used in packaging films, bottles, and agricultural applications due to its flexibility, recyclability, and similarity to conventional PE. BioPET (bio-based polyethylene terephthalate) is widely applied in beverage bottles, textiles, and food containers because of its superior strength, clarity, and barrier properties. While BioPE offers advantages in applications requiring ductility and chemical resistance, BioPET excels in rigid packaging and thermoformable products requiring high durability and transparency.

Biodegradability and End-of-Life Options

BioPE (bio-based polyethylene) offers excellent chemical resistance and recyclability but is not biodegradable, requiring mechanical recycling or energy recovery for end-of-life management. BioPET (bio-based polyethylene terephthalate) combines bio-based content with established recycling streams and limited biodegradability under industrial composting conditions. The choice between BioPE and BioPET depends on specific waste management infrastructure and desired environmental outcomes regarding biodegradability and circularity.

Market Trends and Economic Considerations

BioPE dominates the bioplastic market due to its cost-effective production and compatibility with existing polyethylene recycling infrastructure, driving high adoption in packaging and consumer goods. BioPET commands a growing niche segment by capturing demand for sustainable alternatives in beverage bottles despite higher production costs and complex recycling challenges. Market trends indicate a steady increase in BioPET investment fueled by regulatory pressure and consumer preference for fully recyclable bioplastics, whereas BioPE benefits from scalability and lower price volatility in raw materials.

Future Prospects for BioPE and BioPET

BioPE and BioPET hold significant promise in reducing plastic pollution through their renewable feedstocks and recyclability potential. Advancements in bio-based polymer production and enzymatic recycling technologies are expected to enhance the sustainability and cost-effectiveness of BioPE and BioPET, driving wider adoption across packaging and textile industries. Growing regulatory support and consumer demand for eco-friendly materials position BioPE and BioPET as pivotal components in the transition toward circular bioeconomy solutions.

BioPE vs BioPET Infographic

materialdif.com

materialdif.com