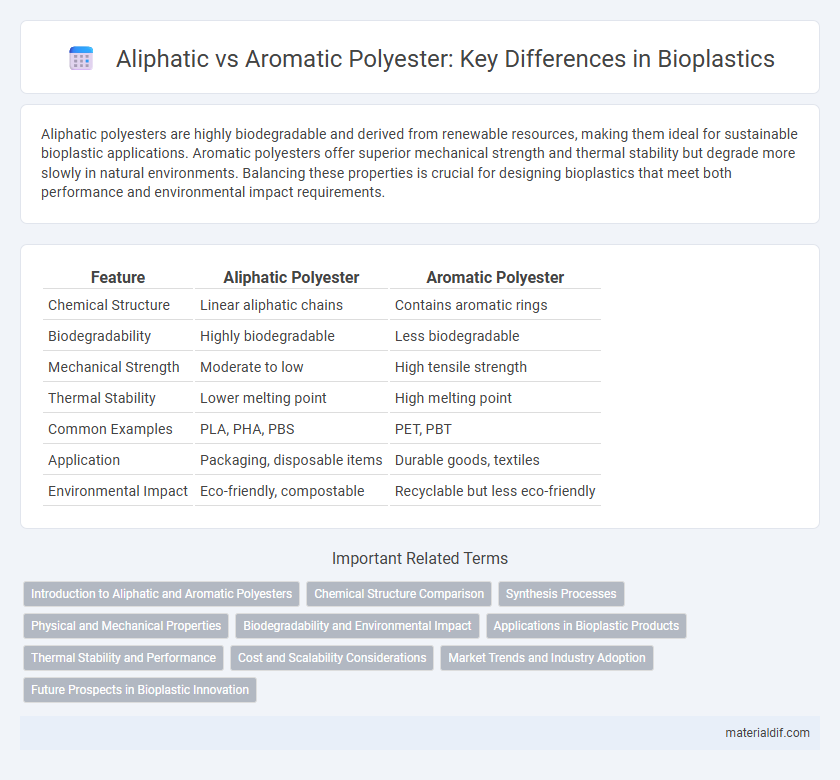

Aliphatic polyesters are highly biodegradable and derived from renewable resources, making them ideal for sustainable bioplastic applications. Aromatic polyesters offer superior mechanical strength and thermal stability but degrade more slowly in natural environments. Balancing these properties is crucial for designing bioplastics that meet both performance and environmental impact requirements.

Table of Comparison

| Feature | Aliphatic Polyester | Aromatic Polyester |

|---|---|---|

| Chemical Structure | Linear aliphatic chains | Contains aromatic rings |

| Biodegradability | Highly biodegradable | Less biodegradable |

| Mechanical Strength | Moderate to low | High tensile strength |

| Thermal Stability | Lower melting point | High melting point |

| Common Examples | PLA, PHA, PBS | PET, PBT |

| Application | Packaging, disposable items | Durable goods, textiles |

| Environmental Impact | Eco-friendly, compostable | Recyclable but less eco-friendly |

Introduction to Aliphatic and Aromatic Polyesters

Aliphatic polyesters, composed primarily of non-aromatic carbon chains, are known for their biodegradability and are widely used in environmentally friendly bioplastics. Aromatic polyesters contain benzene rings within their molecular structure, offering superior mechanical strength and thermal stability but reduced biodegradability. These structural differences influence the performance and environmental impact of bioplastics in packaging, medical, and agricultural applications.

Chemical Structure Comparison

Aliphatic polyesters consist of linear or branched chains primarily composed of carbon and oxygen atoms, resulting in flexible, biodegradable polymers due to their simpler chemical structure. Aromatic polyesters contain benzene rings within their backbone, enhancing rigidity and thermal stability but reducing biodegradability. The presence of aromatic rings in aromatic polyesters increases intermolecular interactions, contrasting with the more hydrolyzable ester linkages in aliphatic polyesters.

Synthesis Processes

Aliphatic polyesters are typically synthesized through ring-opening polymerization of lactones or polycondensation of aliphatic diacids and diols, resulting in biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA). Aromatic polyesters, such as polyethylene terephthalate (PET), are produced via polycondensation reactions involving aromatic diacids (like terephthalic acid) and diols, offering enhanced thermal stability but limited biodegradability. The synthesis of aliphatic polyesters emphasizes renewable monomers and enzymatic catalysts to improve eco-friendliness, while aromatic polyester production relies on petrochemical-derived feedstocks and high-temperature processing.

Physical and Mechanical Properties

Aliphatic polyesters like polylactic acid (PLA) offer high biodegradability and flexibility but tend to have lower tensile strength compared to aromatic polyesters such as polyethylene terephthalate (PET), which exhibit superior mechanical strength and thermal stability. Aromatic polyesters generally provide higher melting points and stiffness, making them ideal for applications requiring durability and resistance to heat. The choice between aliphatic and aromatic polyesters depends on the balance needed between environmental degradation rates and mechanical performance.

Biodegradability and Environmental Impact

Aliphatic polyesters exhibit superior biodegradability due to their aliphatic chains that are readily broken down by microbial enzymes, resulting in lower environmental persistence and reduced accumulation in natural ecosystems. In contrast, aromatic polyesters contain rigid benzene rings that hinder microbial degradation, leading to longer decomposition times and increased environmental impact through microplastic formation. Selecting aliphatic polyesters for bioplastic production enhances compostability and minimizes ecological footprint compared to aromatic polyester-based materials.

Applications in Bioplastic Products

Aliphatic polyesters, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), are widely used in biodegradable packaging, agricultural films, and disposable cutlery due to their excellent biodegradability and compostability. Aromatic polyesters like polyethylene terephthalate (PET) provide superior mechanical strength and thermal stability, making them ideal for durable bioplastic applications such as bottles, fibers, and engineering plastics. The combination of these polyesters enables tailored bioplastic products that balance environmental impact with performance requirements across various industries.

Thermal Stability and Performance

Aliphatic polyesters exhibit lower thermal stability but offer superior biodegradability, making them ideal for environmentally friendly applications, whereas aromatic polyesters demonstrate higher thermal stability and mechanical performance due to their rigid benzene ring structures. The enhanced thermal resistance of aromatic polyesters allows them to maintain integrity at elevated temperatures, suited for high-performance packaging and engineering plastics. In contrast, aliphatic polyesters tend to degrade faster under heat, limiting their use to short-term applications with a focus on sustainability.

Cost and Scalability Considerations

Aliphatic polyesters, such as polylactic acid (PLA), generally offer lower production costs and higher scalability due to simpler synthesis processes and abundant renewable feedstocks. Aromatic polyesters like polyethylene terephthalate (PET) have higher material costs and more complex manufacturing but provide enhanced mechanical properties and thermal resistance. Cost-efficiency and large-scale production favor aliphatic polyesters in bioplastic markets focused on sustainability and volume.

Market Trends and Industry Adoption

Aliphatic polyesters such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) dominate the bioplastic market due to their biodegradability and compatibility with composting infrastructure, driving widespread industry adoption in packaging and agriculture. Aromatic polyesters, including polyethylene terephthalate (PET) variants modified for enhanced biodegradability, are gaining traction in high-performance applications owing to their superior mechanical properties and thermal stability. Market trends indicate increasing investment in aliphatic-aromatic copolymers to balance environmental impact with functional performance, positioning these materials for expanded use in automotive and electronics sectors.

Future Prospects in Bioplastic Innovation

Aliphatic polyesters exhibit superior biodegradability and are increasingly favored for sustainable bioplastic applications due to their rapid environmental degradation and compatibility with composting processes. Aromatic polyesters, while offering enhanced mechanical strength and thermal stability, face challenges in biodegradability, driving research into copolymer blends and chemical modifications to improve environmental performance. Future bioplastic innovation centers on developing hybrid materials that balance the eco-friendly properties of aliphatic polyesters with the durability of aromatic polyesters to meet evolving industry demands for sustainable and high-performance bioplastics.

Aliphatic polyester vs Aromatic polyester Infographic

materialdif.com

materialdif.com