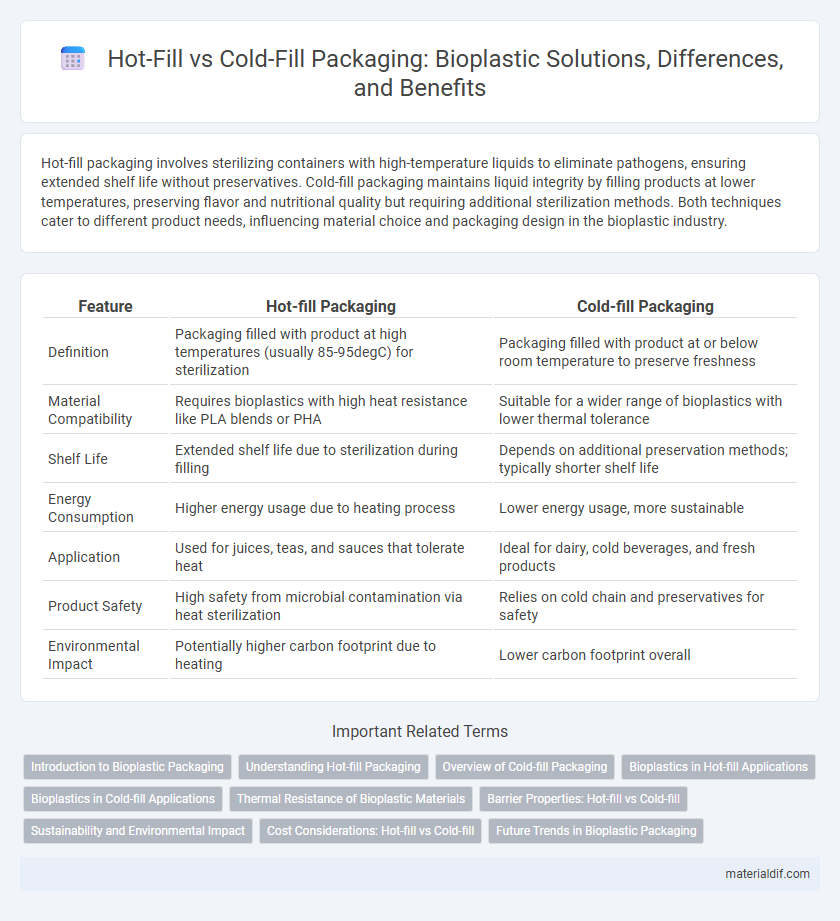

Hot-fill packaging involves sterilizing containers with high-temperature liquids to eliminate pathogens, ensuring extended shelf life without preservatives. Cold-fill packaging maintains liquid integrity by filling products at lower temperatures, preserving flavor and nutritional quality but requiring additional sterilization methods. Both techniques cater to different product needs, influencing material choice and packaging design in the bioplastic industry.

Table of Comparison

| Feature | Hot-fill Packaging | Cold-fill Packaging |

|---|---|---|

| Definition | Packaging filled with product at high temperatures (usually 85-95degC) for sterilization | Packaging filled with product at or below room temperature to preserve freshness |

| Material Compatibility | Requires bioplastics with high heat resistance like PLA blends or PHA | Suitable for a wider range of bioplastics with lower thermal tolerance |

| Shelf Life | Extended shelf life due to sterilization during filling | Depends on additional preservation methods; typically shorter shelf life |

| Energy Consumption | Higher energy usage due to heating process | Lower energy usage, more sustainable |

| Application | Used for juices, teas, and sauces that tolerate heat | Ideal for dairy, cold beverages, and fresh products |

| Product Safety | High safety from microbial contamination via heat sterilization | Relies on cold chain and preservatives for safety |

| Environmental Impact | Potentially higher carbon footprint due to heating | Lower carbon footprint overall |

Introduction to Bioplastic Packaging

Hot-fill packaging uses high temperatures to sterilize bioplastic containers and extend product shelf life, making it ideal for acidic and heat-tolerant liquids. Cold-fill packaging involves filling bioplastic containers at lower temperatures, preserving sensitive nutrients and flavors but requiring stringent hygiene controls. Both methods leverage bioplastic's biodegradability and renewable resources to reduce environmental impact compared to conventional plastic packaging.

Understanding Hot-fill Packaging

Hot-fill packaging utilizes bioplastic containers that withstand high temperatures, typically between 185degF (85degC) and 194degF (90degC), to sterilize products and ensure shelf stability without preservatives. This method preserves the flavor and nutritional quality of beverages by filling the product while hot and sealing it immediately to create a vacuum seal. Bioplastics like PLA and bio-PET offer excellent thermal resistance and sustainability advantages, making them suitable for hot-fill applications in the food and beverage industry.

Overview of Cold-fill Packaging

Cold-fill packaging involves filling containers with products at or near room temperature, reducing the need for energy-intensive sterilization processes compared to hot-fill methods. This technique is particularly suitable for bioplastic containers, as it minimizes thermal stress and preserves material integrity, enhancing sustainability. Cold-fill packaging supports the use of biodegradable materials by maintaining product safety while extending shelf life through controlled atmospheres or preservatives.

Bioplastics in Hot-fill Applications

Bioplastics in hot-fill packaging require specialized formulations to withstand temperatures typically between 85degC and 95degC without deforming or releasing harmful substances. These materials, such as PLA blends with heat-resistant additives, offer improved thermal stability and maintain barrier properties essential for preserving product quality. Adapting bioplastics for hot-fill processes supports sustainable packaging solutions by reducing reliance on traditional plastics while meeting safety and performance standards.

Bioplastics in Cold-fill Applications

Bioplastics in cold-fill packaging excel due to their excellent barrier properties and resistance to moisture at low temperatures, making them ideal for beverages and perishable goods. These materials maintain structural integrity without deformation or leaching, ensuring product safety and extended shelf life. Cold-fill applications benefit from PLA and PHA bioplastics, which offer sustainable alternatives to traditional plastics while supporting recyclability and compostability.

Thermal Resistance of Bioplastic Materials

Hot-fill packaging requires bioplastic materials with high thermal resistance, typically able to withstand temperatures above 85degC without deformation or loss of integrity. Cold-fill packaging allows the use of bioplastics with lower thermal resistance, as the materials only need to maintain stability at ambient or refrigerated conditions. The selection of bioplastic for hot-fill applications often favors polymers like polylactic acid (PLA) or bio-based polyethylene with enhanced thermal modifiers to ensure durability during sterilization and filling processes.

Barrier Properties: Hot-fill vs Cold-fill

Hot-fill packaging requires materials with superior heat resistance and strong barrier properties to withstand temperatures around 85-95degC without compromising product integrity, making bioplastics with enhanced thermal stability essential. Cold-fill packaging operates at ambient temperatures, allowing the use of bioplastics with moderate barrier properties focused on oxygen and moisture retention rather than heat resistance. The choice between hot-fill and cold-fill bioplastic packaging hinges on balancing the necessary barrier properties with thermal requirements to ensure product shelf life and safety.

Sustainability and Environmental Impact

Hot-fill packaging using bioplastics reduces the need for chemical preservatives by applying heat, which can lower environmental impact through decreased food wastage and longer shelf life. Cold-fill packaging, while less energy-intensive during fill, often requires additional additives and refrigeration, increasing the carbon footprint and potential plastic waste. Choosing hot-fill bioplastic packaging supports sustainability goals by optimizing energy use and minimizing preservative chemicals, contributing to lower overall ecological footprints.

Cost Considerations: Hot-fill vs Cold-fill

Hot-fill packaging typically incurs higher initial costs due to the need for heat-resistant bioplastic materials that can withstand temperatures around 85-95degC without deformation. Cold-fill packaging offers cost savings by allowing the use of more common bioplastics, reducing material expenses and energy consumption during filling. Evaluating cost considerations, cold-fill processes often lead to lower overall production expenses, making them economically favorable for large-scale bioplastic packaging applications.

Future Trends in Bioplastic Packaging

Hot-fill packaging using bioplastics is evolving with improved thermal resistance, enabling safe sterilization and filling at temperatures above 85degC, which preserves product quality and extends shelf life. Cold-fill packaging processes are increasingly adopting bioplastic materials with enhanced barrier properties to maintain freshness without heat exposure, supporting energy-efficient production and sustainability goals. Future trends emphasize developing hybrid bioplastic formulations that combine heat tolerance and superior barrier performance, meeting diverse product requirements while reducing environmental impact.

Hot-fill Packaging vs Cold-fill Packaging Infographic

materialdif.com

materialdif.com