Cradle-to-cradle design promotes the creation of bioplastics that can be fully recycled or safely biodegraded, eliminating waste and minimizing environmental impact. In contrast, cradle-to-grave practices result in bioplastics that are disposed of after use, often contributing to pollution and resource depletion. Prioritizing cradle-to-cradle principles ensures sustainable lifecycle management of bioplastic materials, fostering a circular economy.

Table of Comparison

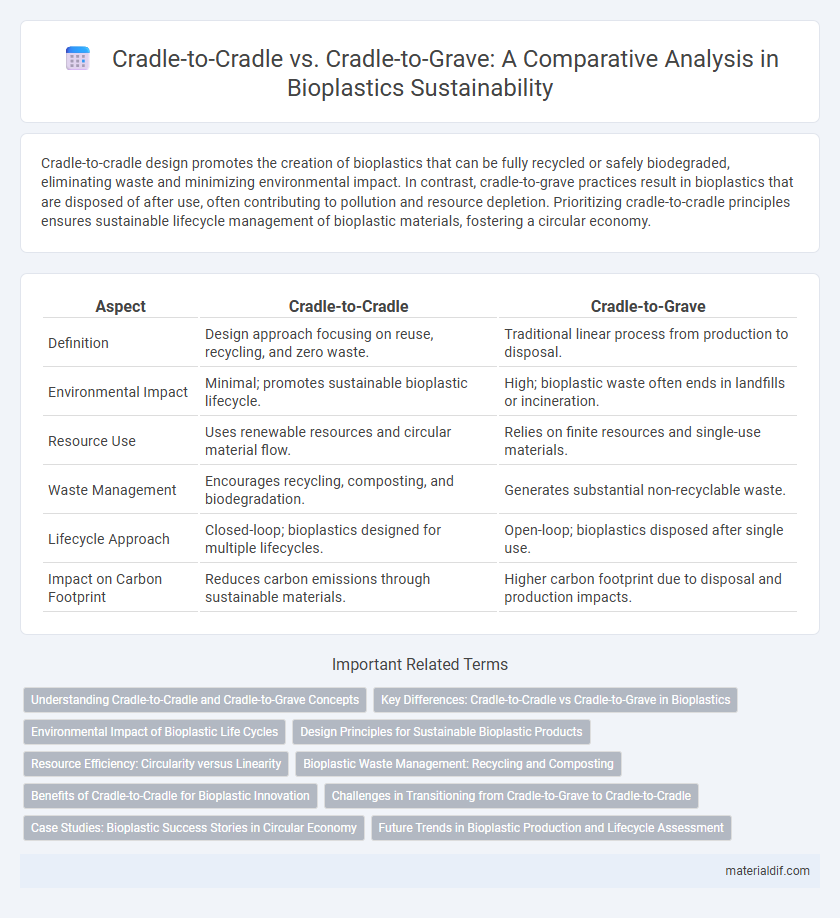

| Aspect | Cradle-to-Cradle | Cradle-to-Grave |

|---|---|---|

| Definition | Design approach focusing on reuse, recycling, and zero waste. | Traditional linear process from production to disposal. |

| Environmental Impact | Minimal; promotes sustainable bioplastic lifecycle. | High; bioplastic waste often ends in landfills or incineration. |

| Resource Use | Uses renewable resources and circular material flow. | Relies on finite resources and single-use materials. |

| Waste Management | Encourages recycling, composting, and biodegradation. | Generates substantial non-recyclable waste. |

| Lifecycle Approach | Closed-loop; bioplastics designed for multiple lifecycles. | Open-loop; bioplastics disposed after single use. |

| Impact on Carbon Footprint | Reduces carbon emissions through sustainable materials. | Higher carbon footprint due to disposal and production impacts. |

Understanding Cradle-to-Cradle and Cradle-to-Grave Concepts

Cradle-to-cradle design emphasizes creating products with a continuous lifecycle, where materials are reused or recycled without generating waste, promoting a circular economy. Cradle-to-grave involves products that follow a linear path from production to disposal, often leading to waste accumulation and environmental degradation. Understanding these concepts is crucial for advancing sustainable bioplastic development, aiming to reduce ecological impact through efficient resource management and closed-loop systems.

Key Differences: Cradle-to-Cradle vs Cradle-to-Grave in Bioplastics

Cradle-to-cradle bioplastics emphasize the continuous recycling and reuse of materials, promoting a closed-loop system that minimizes waste and environmental impact. In contrast, cradle-to-grave bioplastics follow a linear lifecycle, ending in disposal or degradation, which can contribute to pollution and resource depletion. Key differences include the sustainability focus of cradle-to-cradle bioplastics versus the finite lifecycle and environmental burden associated with cradle-to-grave models.

Environmental Impact of Bioplastic Life Cycles

Cradle-to-cradle design in bioplastics emphasizes continuous reuse and recycling, minimizing waste and reducing environmental impact compared to cradle-to-grave models that often lead to landfill accumulation. Bioplastic life cycles under cradle-to-cradle frameworks significantly lower carbon footprints by promoting biodegradable materials and closed-loop systems. This approach enhances sustainability by mitigating pollution and conserving resources throughout the bioplastic's entire life span.

Design Principles for Sustainable Bioplastic Products

Cradle-to-cradle design principles emphasize creating bioplastic products with materials that can be fully recycled or safely composted, ensuring continuous reuse in closed-loop systems. These principles prioritize non-toxic, biodegradable components that enhance the product's lifecycle while minimizing environmental impact, unlike cradle-to-grave approaches which often lead to waste accumulation. Sustainable bioplastic design focuses on regenerative resource cycles, material health, and product circularity, driving innovation toward zero-waste solutions.

Resource Efficiency: Circularity versus Linearity

Cradle-to-cradle design promotes circularity by continuously reusing materials, reducing waste and conserving resources, unlike the cradle-to-grave approach that follows a linear path from resource extraction to disposal. This circular model enhances resource efficiency by enabling product components to be safely returned to the production cycle. By contrast, cradle-to-grave systems lead to resource depletion and increased environmental impact due to their linear use and disposal method.

Bioplastic Waste Management: Recycling and Composting

Cradle-to-cradle bioplastic waste management emphasizes recycling and composting processes that convert bioplastics into reusable materials or nutrient-rich compost, minimizing landfill impact and reducing environmental harm. Cradle-to-grave approaches typically result in bioplastics being disposed of in landfills or incinerated, leading to resource depletion and increased greenhouse gas emissions. Advanced recycling technologies and industrial composting facilities enhance the sustainability of cradle-to-cradle systems by enabling circular material flows and reducing bioplastic waste accumulation.

Benefits of Cradle-to-Cradle for Bioplastic Innovation

Cradle-to-cradle design promotes the continuous reuse of bioplastic materials, minimizing waste and reducing reliance on fossil fuels compared to the cradle-to-grave model, which often results in landfill accumulation and environmental pollution. By emphasizing biodegradability and recyclability, cradle-to-cradle enhances the sustainability and lifecycle efficiency of bioplastics, driving innovation in compostable and fully recyclable biopolymer formulations. This approach supports circular economy principles, improving resource efficiency and enabling bioplastic products to maintain value throughout their entire lifecycle.

Challenges in Transitioning from Cradle-to-Grave to Cradle-to-Cradle

Transitioning from cradle-to-grave to cradle-to-cradle presents significant challenges, including redesigning products for full recyclability and sourcing sustainable, non-toxic materials to enable continuous biological or technical cycles. Infrastructure limitations hinder efficient recovery and recycling processes, while economic barriers arise from higher initial costs and market resistance to sustainable alternatives. Overcoming these obstacles requires systemic changes in supply chains, consumer behavior, and regulatory frameworks to support circular economy principles in bioplastic industries.

Case Studies: Bioplastic Success Stories in Circular Economy

Cradle-to-cradle approaches in bioplastic production emphasize closed-loop systems where materials are continuously recycled or safely composted, minimizing waste and environmental impact. Case studies like the use of PLA-based packaging by companies such as NatureWorks demonstrate significant reductions in carbon footprint and landfill contributions compared to traditional plastics. These success stories highlight how integrating cradle-to-cradle principles enables bioplastics to play a pivotal role in advancing circular economy goals.

Future Trends in Bioplastic Production and Lifecycle Assessment

Future trends in bioplastic production emphasize cradle-to-cradle approaches, promoting circularity by designing materials for complete recyclability and biodegradability. Lifecycle assessment (LCA) increasingly highlights the environmental benefits of closed-loop systems, reducing carbon footprints and resource depletion compared to traditional cradle-to-grave models. Innovations in feedstock sourcing and chemical recycling technologies are accelerating the shift towards sustainable bioplastic cycles, fostering long-term ecological balance.

Cradle-to-cradle vs Cradle-to-grave Infographic

materialdif.com

materialdif.com