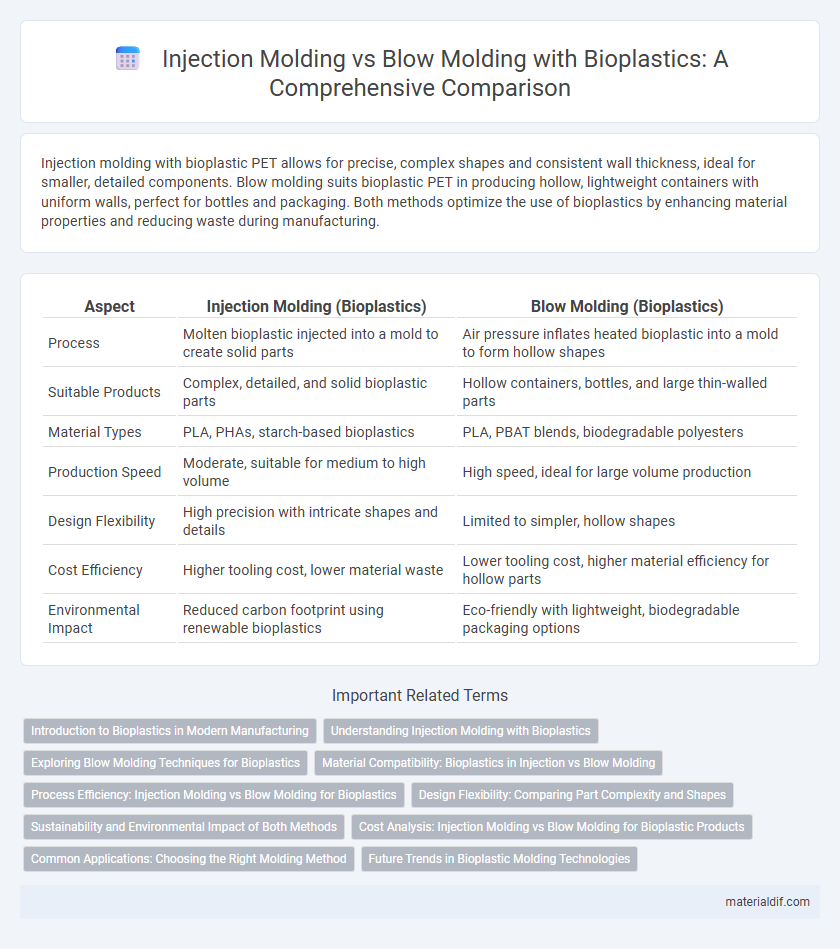

Injection molding with bioplastic PET allows for precise, complex shapes and consistent wall thickness, ideal for smaller, detailed components. Blow molding suits bioplastic PET in producing hollow, lightweight containers with uniform walls, perfect for bottles and packaging. Both methods optimize the use of bioplastics by enhancing material properties and reducing waste during manufacturing.

Table of Comparison

| Aspect | Injection Molding (Bioplastics) | Blow Molding (Bioplastics) |

|---|---|---|

| Process | Molten bioplastic injected into a mold to create solid parts | Air pressure inflates heated bioplastic into a mold to form hollow shapes |

| Suitable Products | Complex, detailed, and solid bioplastic parts | Hollow containers, bottles, and large thin-walled parts |

| Material Types | PLA, PHAs, starch-based bioplastics | PLA, PBAT blends, biodegradable polyesters |

| Production Speed | Moderate, suitable for medium to high volume | High speed, ideal for large volume production |

| Design Flexibility | High precision with intricate shapes and details | Limited to simpler, hollow shapes |

| Cost Efficiency | Higher tooling cost, lower material waste | Lower tooling cost, higher material efficiency for hollow parts |

| Environmental Impact | Reduced carbon footprint using renewable bioplastics | Eco-friendly with lightweight, biodegradable packaging options |

Introduction to Bioplastics in Modern Manufacturing

Injection molding with bioplastics offers precise, high-volume production of complex shapes, ideal for manufacturing detailed components with consistent quality. Blow molding suits the creation of hollow bioplastic products such as bottles and containers, optimizing material use and ensuring lightweight, durable packaging. Both techniques leverage renewable, biodegradable materials like polylactic acid (PLA) and polyhydroxyalkanoates (PHA), advancing sustainable manufacturing and reducing reliance on fossil-fuel-based plastics.

Understanding Injection Molding with Bioplastics

Injection molding with bioplastics involves melting biodegradable polymers such as PLA or PHA and injecting them into precision-engineered molds to create complex, high-strength components. This process offers superior dimensional accuracy and surface finish compared to blow molding, making it ideal for detailed and durable bioplastic products like medical devices and consumer goods. Optimizing parameters such as melt temperature, injection pressure, and cooling time is crucial to prevent degradation and ensure the structural integrity of bioplastic parts.

Exploring Blow Molding Techniques for Bioplastics

Blow molding techniques for bioplastics enable the production of hollow, lightweight containers such as bottles and jars, utilizing the material's biodegradability and strength. Compared to injection molding, blow molding offers superior efficiency in creating uniform wall thickness and complex cavity shapes ideal for packaging applications. Advanced bioplastic formulations like PLA and PHA exhibit excellent compatibility with extrusion blow molding processes, optimizing material usage and reducing environmental impact.

Material Compatibility: Bioplastics in Injection vs Blow Molding

Bioplastics such as PLA and PHA exhibit distinct compatibility with injection and blow molding processes, where injection molding accommodates higher viscosity biopolymers and offers precise dimensional control. Blow molding suits bioplastics like bio-PET and bio-HDPE with good melt strength required for hollow parts, enabling lightweight container production. Material selection critically impacts processing parameters and final product performance in both molding techniques using bioplastics.

Process Efficiency: Injection Molding vs Blow Molding for Bioplastics

Injection molding of bioplastics offers high precision and fast cycle times, making it ideal for complex, detailed parts with consistent quality. Blow molding excels in producing hollow, lightweight containers efficiently, optimizing material use and minimizing waste in bioplastic applications. Process efficiency depends on part geometry and production volume, with injection molding suited for intricate shapes and blow molding preferred for large-scale bottle manufacturing.

Design Flexibility: Comparing Part Complexity and Shapes

Injection molding with bioplastics allows for intricate part complexity and detailed shapes due to precise mold cavity design, making it ideal for high-precision components. Blow molding is better suited for hollow, lightweight containers with simpler geometric forms, benefiting from efficient volume production and reduced material waste. Design flexibility in bioplastics depends on desired product geometry, with injection molding enabling complex, solid parts and blow molding excelling at creating uniform, hollow shapes.

Sustainability and Environmental Impact of Both Methods

Injection molding with bioplastics offers precise control over material use, minimizing waste and energy consumption compared to blow molding. Blow molding often requires more raw material and energy due to its process of inflating molten bioplastic, resulting in higher environmental impact. Both methods benefit from using renewable biopolymer feedstocks, but injection molding typically provides a more sustainable production cycle through optimized material efficiency and reduced greenhouse gas emissions.

Cost Analysis: Injection Molding vs Blow Molding for Bioplastic Products

Injection molding of bioplastics typically incurs higher initial tooling costs due to the complexity of dies but offers lower per-unit costs for high-volume production. Blow molding has lower tooling expenses and faster cycle times, making it cost-effective for lightweight, hollow bioplastic containers at medium volumes. Evaluating cost efficiency depends on production scale, product geometry, and material characteristics of bioplastics such as PLA or PHAs.

Common Applications: Choosing the Right Molding Method

Injection molding with bioplastics excels in producing complex, high-precision components like automotive parts, medical devices, and consumer electronics housings due to its ability to create detailed shapes with tight tolerances. Blow molding is preferred for manufacturing hollow bioplastic containers such as bottles, jars, and fuel tanks, offering cost-effective large-volume production with uniform wall thickness. Selecting the right molding method depends on the desired product geometry, application requirements, and production scale in bioplastic manufacturing.

Future Trends in Bioplastic Molding Technologies

Future trends in bioplastic molding technologies highlight increasing adoption of injection molding for its precision and ability to handle complex geometries with biodegradable polymers such as PLA and PHA. Blow molding is evolving to accommodate lightweight, flexible packaging solutions utilizing starch-based bioplastics, meeting rising demand for sustainable containers. Advances in machine efficiency and material formulations are driving cost reduction and improved performance in both molding techniques, supporting broader bioplastic commercialization.

Injection molding vs Blow molding (with bioplastics) Infographic

materialdif.com

materialdif.com