Extrusion and injection molding are key processing methods for shaping bioplastics, each offering distinct advantages depending on the application. Extrusion is ideal for creating continuous shapes such as films, sheets, and pipes, providing consistent quality and efficient production for biodegradable materials. Injection molding excels in producing complex, high-precision parts with excellent surface finishes, making it suitable for bioplastic items like packaging, utensils, and medical devices.

Table of Comparison

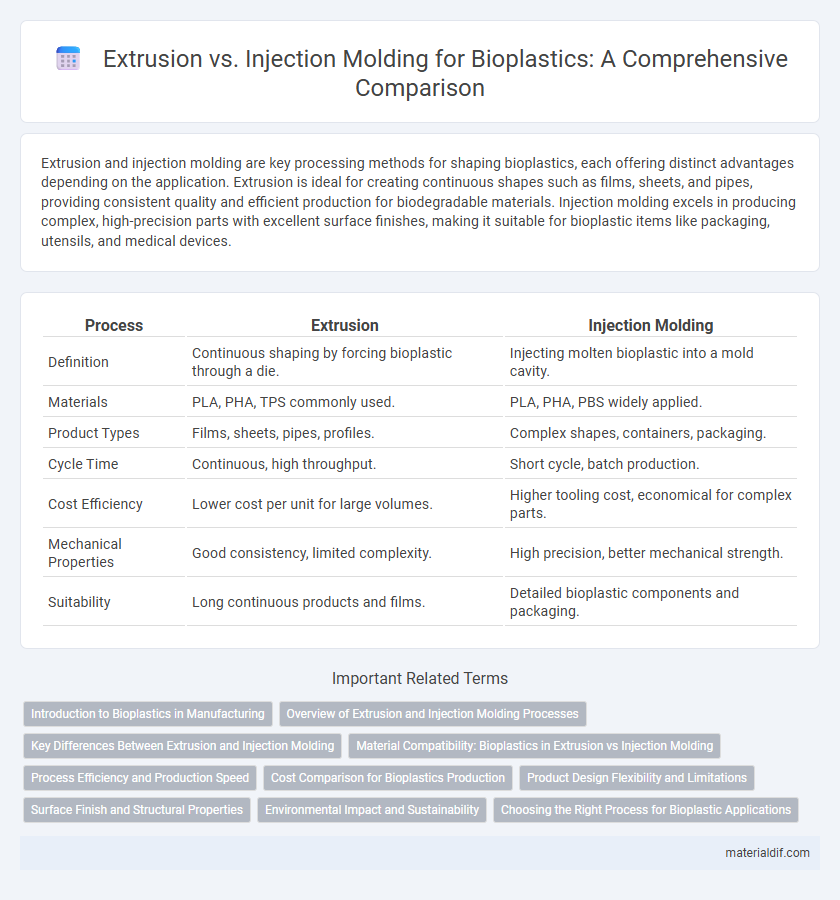

| Process | Extrusion | Injection Molding |

|---|---|---|

| Definition | Continuous shaping by forcing bioplastic through a die. | Injecting molten bioplastic into a mold cavity. |

| Materials | PLA, PHA, TPS commonly used. | PLA, PHA, PBS widely applied. |

| Product Types | Films, sheets, pipes, profiles. | Complex shapes, containers, packaging. |

| Cycle Time | Continuous, high throughput. | Short cycle, batch production. |

| Cost Efficiency | Lower cost per unit for large volumes. | Higher tooling cost, economical for complex parts. |

| Mechanical Properties | Good consistency, limited complexity. | High precision, better mechanical strength. |

| Suitability | Long continuous products and films. | Detailed bioplastic components and packaging. |

Introduction to Bioplastics in Manufacturing

Extrusion and injection molding are prevalent manufacturing processes for bioplastics, each offering distinct advantages for shaping biodegradable polymers. Extrusion continuously produces uniform bioplastic profiles, sheets, and films by forcing molten bioplastic material through a shaped die, ideal for packaging and agricultural applications. Injection molding efficiently creates complex, high-precision bioplastic parts by injecting molten bioplastic into molds, commonly used in automotive components and consumer goods.

Overview of Extrusion and Injection Molding Processes

Extrusion involves continuously melting and shaping bioplastic material through a die to create long, uniform profiles such as films, sheets, or tubes, ideal for applications requiring consistent cross sections. Injection molding presses molten bioplastic into a mold cavity under high pressure, enabling the production of complex, detailed, and high-strength parts with precise dimensional accuracy. Both processes accommodate bioplastics like PLA and PHA, but extrusion excels in continuous production while injection molding is preferred for intricate, high-volume components.

Key Differences Between Extrusion and Injection Molding

Extrusion shapes bioplastics by continuously forcing molten material through a die to create uniform profiles like films, sheets, or tubes, while injection molding injects molten bioplastic into molds to form complex, precise shapes such as containers and automotive parts. Extrusion is ideal for producing long, consistent shapes at high volumes, whereas injection molding excels in manufacturing detailed, high-strength components with intricate geometries. Temperature control, cooling rates, and pressure differ significantly between the two processes, impacting the mechanical properties and clarity of bioplastic products.

Material Compatibility: Bioplastics in Extrusion vs Injection Molding

Bioplastics exhibit distinct compatibility profiles in extrusion and injection molding, where extrusion suits materials like PLA and PHA due to their thermal stability and flow characteristics, enabling continuous shaping into films and sheets. Injection molding accommodates bioplastics such as TPS and PBS that require precise temperature control to prevent degradation and ensure dimensional accuracy in complex parts. Understanding the thermal and rheological properties of each bioplastic is crucial for optimizing processing parameters in these methods to maintain material integrity and performance.

Process Efficiency and Production Speed

Extrusion offers continuous production with high throughput, making it highly efficient for creating uniform bioplastic sheets, films, and profiles. Injection molding provides faster cycle times and precision for complex bioplastic parts, optimizing material usage and reducing waste. While extrusion suits large-volume, simpler shapes, injection molding excels in rapid, detailed component manufacturing, balancing process efficiency and production speed depending on product requirements.

Cost Comparison for Bioplastics Production

Extrusion for bioplastics offers lower upfront costs due to simpler machinery and continuous processing, making it cost-effective for high-volume production of films and sheets. Injection molding involves higher initial investment in molds and equipment but enables precise shaping and faster cycle times, reducing per-unit costs for complex bioplastic parts at scale. Production cost efficiency depends on product complexity, volume, and material type, with extrusion preferred for simpler forms and injection molding advantageous for detailed components requiring tight tolerances.

Product Design Flexibility and Limitations

Extrusion offers continuous production ideal for creating uniform bioplastic sheets, films, and pipes with consistent thickness, but it limits product complexity due to its linear shaping process. Injection molding provides greater design flexibility for bioplastics, enabling intricate geometries, detailed features, and high precision in mass-produced components. However, injection molding involves higher initial mold costs and longer cycle times compared to extrusion, influencing design and manufacturing decisions.

Surface Finish and Structural Properties

Extrusion of bioplastics produces continuous profiles with uniform surface finish ideal for films and sheets, but typically exhibits lower dimensional precision compared to injection molding. Injection molding offers superior surface finish quality with intricate detail replication and enhanced mechanical strength due to controlled cooling and high pressure during molding. Structural properties of injection-molded bioplastics often surpass those of extruded products, providing better impact resistance and durability for complex parts.

Environmental Impact and Sustainability

Extrusion and injection molding of bioplastics differ significantly in environmental impact, with extrusion typically generating less waste due to continuous processing and lower energy consumption. Injection molding consumes more energy during the melting and cooling cycles but allows for precise material use, reducing excess scrap and enabling more complex, lightweight designs that improve sustainability. Both methods benefit from bioplastic feedstocks that are renewable and biodegradable, but extrusion's lower carbon footprint and energy efficiency make it preferable for large-scale, eco-friendly production.

Choosing the Right Process for Bioplastic Applications

Extrusion offers continuous production ideal for creating films, sheets, and pipes from bioplastics, providing consistent thickness and high output rates. Injection molding suits complex, high-precision bioplastic parts with rapid cycle times and minimal material waste, making it preferable for consumer goods and medical devices. Selecting the right process depends on application requirements, product geometry, and production volume to optimize the performance and sustainability of bioplastic components.

Extrusion vs Injection molding (for bioplastics) Infographic

materialdif.com

materialdif.com