Blown film extrusion creates tubular films by inflating molten bioplastic through a circular die, producing films with superior strength, clarity, and uniform thickness ideal for flexible packaging. Cast film extrusion involves pouring molten bioplastic onto a chilled drum, resulting in films with smooth surfaces and precise gauge control suitable for applications requiring high optical clarity. Blown films typically offer better mechanical properties and wider orientation, while cast films excel in uniformity and surface finish, making the choice dependent on specific bioplastic pet product requirements.

Table of Comparison

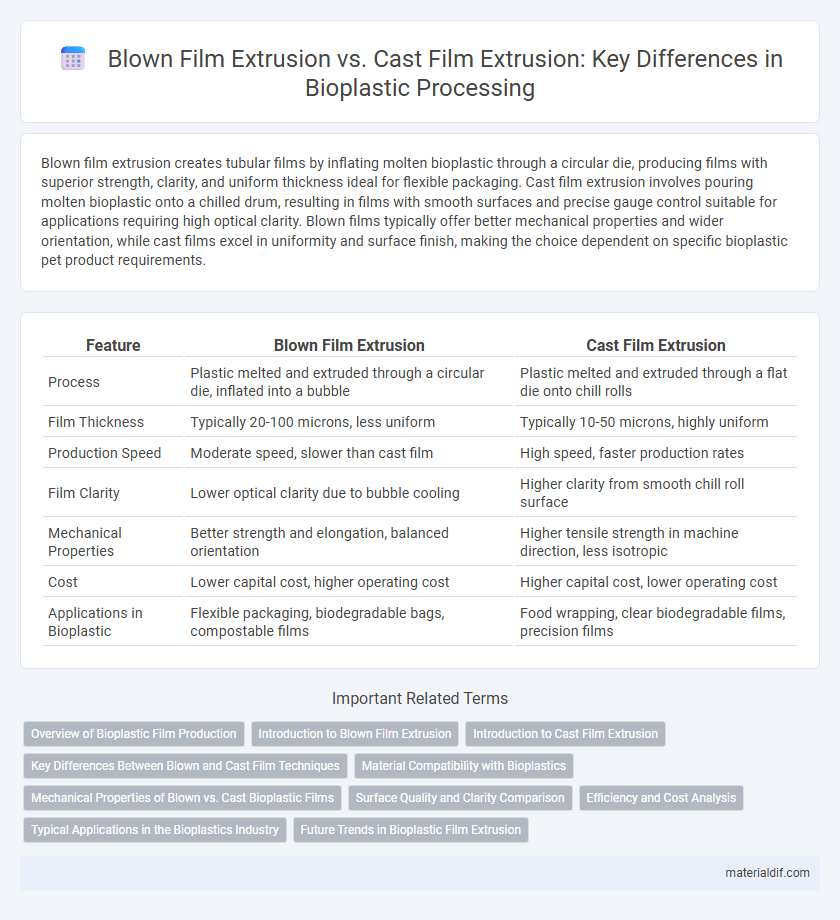

| Feature | Blown Film Extrusion | Cast Film Extrusion |

|---|---|---|

| Process | Plastic melted and extruded through a circular die, inflated into a bubble | Plastic melted and extruded through a flat die onto chill rolls |

| Film Thickness | Typically 20-100 microns, less uniform | Typically 10-50 microns, highly uniform |

| Production Speed | Moderate speed, slower than cast film | High speed, faster production rates |

| Film Clarity | Lower optical clarity due to bubble cooling | Higher clarity from smooth chill roll surface |

| Mechanical Properties | Better strength and elongation, balanced orientation | Higher tensile strength in machine direction, less isotropic |

| Cost | Lower capital cost, higher operating cost | Higher capital cost, lower operating cost |

| Applications in Bioplastic | Flexible packaging, biodegradable bags, compostable films | Food wrapping, clear biodegradable films, precision films |

Overview of Bioplastic Film Production

Blown film extrusion of bioplastics produces tubular films by inflating molten polymer through a circular die, enabling better mechanical properties and uniform thickness. Cast film extrusion involves extruding bioplastic melt onto a chill roll, resulting in films with superior clarity and consistent gauge control. Both methods are critical in bioplastic film production, with blown films suited for flexible packaging and cast films preferred for applications requiring smooth surface finish.

Introduction to Blown Film Extrusion

Blown film extrusion is a widely used process for manufacturing bioplastic films, where molten polymer is extruded through a circular die and inflated into a thin tube, resulting in a versatile and uniform film. This method allows precise control over film thickness, mechanical properties, and barrier performance, essential for sustainable packaging solutions in the bioplastic industry. Compared to cast film extrusion, blown film extrusion offers superior film strength, elasticity, and cost-effective production, making it ideal for biodegradable and compostable film applications.

Introduction to Cast Film Extrusion

Cast film extrusion produces thin, uniform bioplastic films by extruding molten polymer onto a cooled roll, allowing precise control over thickness and surface properties. This method is favored for producing high-quality bioplastic packaging films with excellent clarity and mechanical strength. Compared to blown film extrusion, cast film extrusion offers faster production speeds and better dimensional stability for biodegradable polymers.

Key Differences Between Blown and Cast Film Techniques

Blown film extrusion forms bioplastic films by inflating a molten polymer tube, offering superior tensile strength and uniform orientation, while cast film extrusion involves cooling a molten polymer on a chill roll for higher clarity and smoother surface finish. Blown films typically exhibit better puncture resistance and stretchability, making them ideal for packaging applications requiring durability. Cast films allow greater control over film thickness and offer faster production speeds, benefiting applications where optical properties and uniform thickness are critical.

Material Compatibility with Bioplastics

Blown film extrusion offers superior oxygen barrier properties crucial for bioplastics like PLA and PHA, enhancing their application in sustainable packaging. Cast film extrusion provides better clarity and surface smoothness, making it ideal for bioplastics that require high optical quality such as bio-PET. Material compatibility in blown film extrusion suits biodegradable polymers with flexible mechanical properties, while cast film extrusion excels with rigid or semi-rigid bioplastics due to precise temperature control.

Mechanical Properties of Blown vs. Cast Bioplastic Films

Blown film extrusion of bioplastics typically yields films with superior tensile strength and improved elongation due to molecular orientation during the cooling process, enhancing mechanical resilience. Cast film extrusion produces bioplastic films with better clarity and uniform thickness but generally exhibits lower tear resistance and tensile strength compared to blown films. The choice between blown and cast extrusion affects mechanical properties crucial for packaging durability, with blown films offering enhanced toughness for flexible applications.

Surface Quality and Clarity Comparison

Blown film extrusion produces bioplastic films with superior tensile strength and better mechanical properties, but often exhibits lower surface quality and reduced clarity due to uneven cooling and film orientation. Cast film extrusion offers enhanced surface smoothness and higher optical clarity because of rapid quenching on chilled rollers, resulting in films with a more uniform thickness and improved transparency. Surface quality and clarity are critical for packaging applications, making cast film extrusion the preferred method when visual appeal and product presentation are priorities.

Efficiency and Cost Analysis

Blown film extrusion offers higher material efficiency by using air pressure to stretch bioplastic into thin films with minimal waste, resulting in cost savings for large-scale production. Cast film extrusion provides superior surface quality and thickness uniformity, but its slower cooling rates and higher energy consumption increase overall production costs. Evaluating efficiency and cost, blown film extrusion is generally more economical for volume-driven bioplastic film manufacturing, while cast film suits applications demanding precision and premium quality.

Typical Applications in the Bioplastics Industry

Blown film extrusion is commonly used in packaging applications such as biodegradable bags, agricultural films, and compostable wraps due to its ability to produce durable, flexible films with good barrier properties. Cast film extrusion is favored for producing smooth, high-clarity films used in food packaging, laminations, and medical-grade bioplastics where transparency and stiffness are critical. Both methods optimize the performance of bioplastic materials like PLA, PHA, and starch-based blends in environmentally friendly packaging solutions.

Future Trends in Bioplastic Film Extrusion

Blown film extrusion offers superior mechanical properties and better barrier performance in bioplastic films, driving its adoption in sustainable packaging solutions. Cast film extrusion provides enhanced clarity and uniform thickness, making it ideal for biodegradable food wraps and agricultural films. Future trends indicate increased integration of nanomaterials and bio-based additives to enhance the functional properties and environmental benefits of bioplastic films in both extrusion methods.

Blown film extrusion vs Cast film extrusion Infographic

materialdif.com

materialdif.com