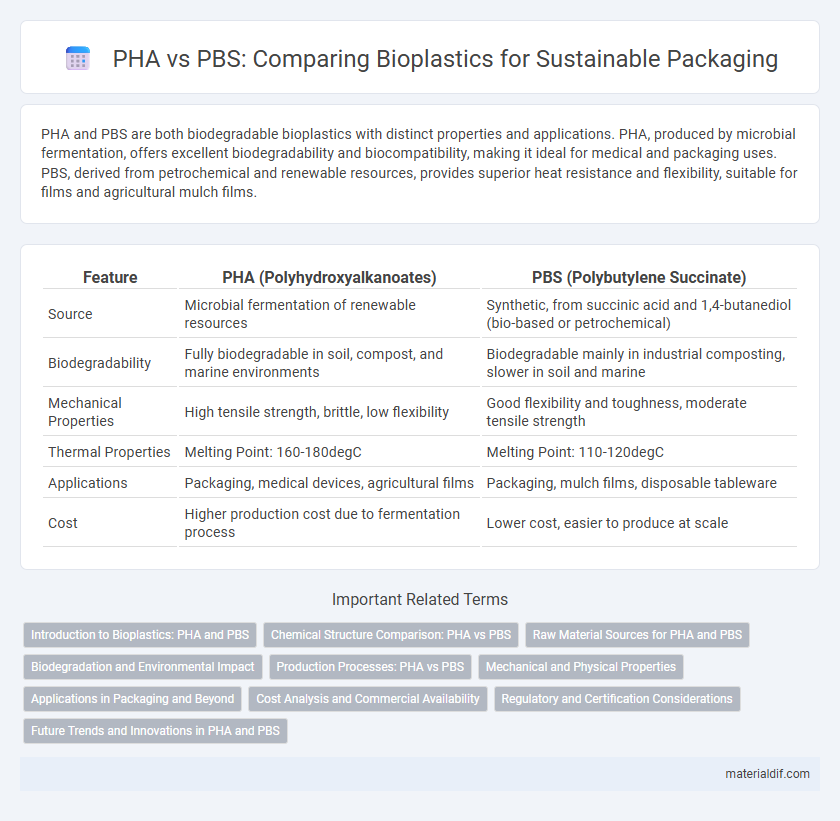

PHA and PBS are both biodegradable bioplastics with distinct properties and applications. PHA, produced by microbial fermentation, offers excellent biodegradability and biocompatibility, making it ideal for medical and packaging uses. PBS, derived from petrochemical and renewable resources, provides superior heat resistance and flexibility, suitable for films and agricultural mulch films.

Table of Comparison

| Feature | PHA (Polyhydroxyalkanoates) | PBS (Polybutylene Succinate) |

|---|---|---|

| Source | Microbial fermentation of renewable resources | Synthetic, from succinic acid and 1,4-butanediol (bio-based or petrochemical) |

| Biodegradability | Fully biodegradable in soil, compost, and marine environments | Biodegradable mainly in industrial composting, slower in soil and marine |

| Mechanical Properties | High tensile strength, brittle, low flexibility | Good flexibility and toughness, moderate tensile strength |

| Thermal Properties | Melting Point: 160-180degC | Melting Point: 110-120degC |

| Applications | Packaging, medical devices, agricultural films | Packaging, mulch films, disposable tableware |

| Cost | Higher production cost due to fermentation process | Lower cost, easier to produce at scale |

Introduction to Bioplastics: PHA and PBS

Polyhydroxyalkanoates (PHA) and Polybutylene Succinate (PBS) are two prominent types of bioplastics derived from renewable resources. PHA is produced through microbial fermentation of sugars or lipids, offering biodegradability in various environments such as soil and marine settings. PBS, a synthetic biopolyester made from succinic acid and 1,4-butanediol, provides excellent thermal and mechanical properties while also being biodegradable under industrial composting conditions.

Chemical Structure Comparison: PHA vs PBS

Polyhydroxyalkanoates (PHA) are polyesters composed of hydroxy fatty acid monomers linked by ester bonds, characterized by a repeating unit of 3-hydroxy alkanoic acids derived from microbial fermentation. Polybutylene succinate (PBS) is a semi-crystalline aliphatic polyester formed from the polycondensation of 1,4-butanediol and succinic acid, exhibiting a linear structure with repeating butylene and succinate units. The key chemical difference lies in PHA's biosynthesized microbial origin with varied monomer composition, versus PBS's chemically synthesized, consistent diacid and diol components, affecting biodegradability and mechanical properties.

Raw Material Sources for PHA and PBS

PHA (polyhydroxyalkanoates) are bioplastics derived from microbial fermentation of renewable resources such as sugar, vegetable oils, and agricultural waste. PBS (polybutylene succinate) is synthesized from petrochemical-derived succinic acid and 1,4-butanediol, although bio-based routes using glucose or starch as feedstocks are increasingly used to produce these monomers sustainably. The raw material sources for PHA emphasize organic biomass conversion, while PBS raw materials largely depend on either fossil-based chemicals or bio-refineries employing carbohydrate-rich crops.

Biodegradation and Environmental Impact

Polyhydroxyalkanoates (PHA) exhibit superior biodegradation rates in marine and soil environments compared to polybutylene succinate (PBS), breaking down completely within months without releasing harmful residues. PBS, while biodegradable under industrial composting conditions, degrades slower in natural settings and may require higher temperatures to initiate decomposition. Both bioplastics reduce reliance on fossil fuels, but PHA's microbial origin and rapid biodegradation contribute to a lower environmental footprint, making it more suitable for eco-friendly packaging and single-use products.

Production Processes: PHA vs PBS

Polyhydroxyalkanoates (PHA) are produced through microbial fermentation of renewable substrates, utilizing bacteria that accumulate PHA as intracellular granules under nutrient-limited conditions. Polybutylene succinate (PBS) is synthesized chemically via polycondensation of succinic acid and 1,4-butanediol, both of which can be derived from fossil fuels or bio-based sources. The biological production process of PHA allows for tailored monomer composition, whereas PBS production relies on established petrochemical or bio-refined pathways, impacting scalability and cost.

Mechanical and Physical Properties

Polyhydroxyalkanoates (PHA) exhibit higher tensile strength and stiffness compared to polybutylene succinate (PBS), making them suitable for applications requiring rigid materials. PBS offers superior flexibility and impact resistance, with better elongation at break, enhancing its use in flexible packaging and films. Both bioplastics demonstrate biodegradability and thermal stability, but PBS generally has a lower melting point, influencing processing conditions and end-use performance.

Applications in Packaging and Beyond

Polyhydroxyalkanoates (PHA) offer excellent biodegradability and biocompatibility, making them ideal for food packaging, medical implants, and agricultural films. Polybutylene succinate (PBS) provides superior thermal and mechanical properties, suited for rigid packaging, disposable cutlery, and compostable bags. Both bioplastics contribute to sustainable packaging solutions while expanding into textiles, automotive parts, and consumer goods, supporting circular economy initiatives.

Cost Analysis and Commercial Availability

Polyhydroxyalkanoates (PHA) generally exhibit higher production costs compared to Polybutylene Succinate (PBS) due to complex fermentation processes and limited feedstock options, impacting their price competitiveness in the bioplastic market. PBS benefits from established petrochemical-based synthesis routes and scalable production facilities, resulting in more affordable pricing and wider commercial availability. Market adoption trends show PBS leading in packaging and agricultural applications while PHA's biodegradability and biocompatibility drive niche markets despite higher costs.

Regulatory and Certification Considerations

PHA (Polyhydroxyalkanoates) and PBS (Polybutylene Succinate) differ in regulatory and certification landscapes, impacting their market adoption in bioplastics. PHA benefits from broader certifications such as ASTM D6400 and EN 13432, ensuring industrial compostability compliance aligned with global standards, which facilitates regulatory acceptance in regions including the EU and US. PBS faces evolving but less extensive certification, often requiring additional testing to meet compostability and biodegradability criteria, influencing its regulatory positioning in packaging and agricultural applications.

Future Trends and Innovations in PHA and PBS

Polyhydroxyalkanoates (PHA) and polybutylene succinate (PBS) are at the forefront of bioplastic innovation with advancements targeting enhanced biodegradability and mechanical properties. Emerging research emphasizes bioengineered microbial strains for cost-effective PHA production and the development of PBS composites with improved thermal stability for broader industrial use. Future trends suggest integration of PHA and PBS into circular economy models, promoting sustainable packaging solutions and reducing reliance on fossil-derived plastics.

PHA vs PBS Infographic

materialdif.com

materialdif.com