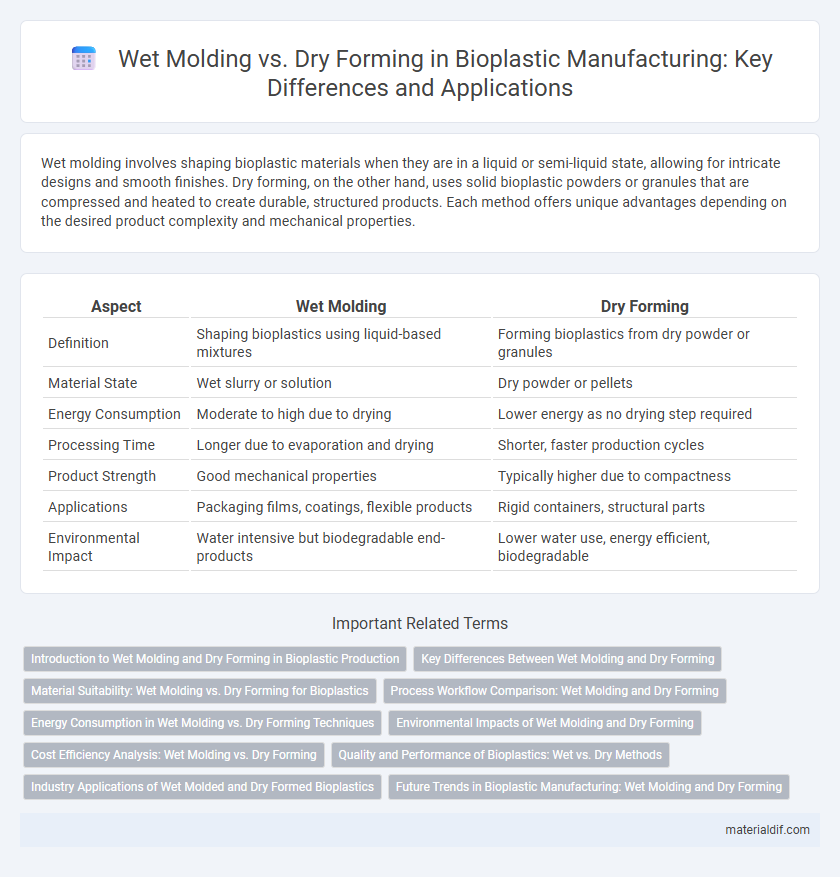

Wet molding involves shaping bioplastic materials when they are in a liquid or semi-liquid state, allowing for intricate designs and smooth finishes. Dry forming, on the other hand, uses solid bioplastic powders or granules that are compressed and heated to create durable, structured products. Each method offers unique advantages depending on the desired product complexity and mechanical properties.

Table of Comparison

| Aspect | Wet Molding | Dry Forming |

|---|---|---|

| Definition | Shaping bioplastics using liquid-based mixtures | Forming bioplastics from dry powder or granules |

| Material State | Wet slurry or solution | Dry powder or pellets |

| Energy Consumption | Moderate to high due to drying | Lower energy as no drying step required |

| Processing Time | Longer due to evaporation and drying | Shorter, faster production cycles |

| Product Strength | Good mechanical properties | Typically higher due to compactness |

| Applications | Packaging films, coatings, flexible products | Rigid containers, structural parts |

| Environmental Impact | Water intensive but biodegradable end-products | Lower water use, energy efficient, biodegradable |

Introduction to Wet Molding and Dry Forming in Bioplastic Production

Wet molding in bioplastic production involves shaping materials by applying moisture to enhance pliability and facilitate detailed mold formation, improving surface finish and structural integrity. Dry forming uses dry bioplastic powders compressed under high pressure to create solid forms without moisture, offering faster processing and reduced drying times. Both methods optimize biopolymer properties for sustainable product manufacturing while balancing efficiency and material characteristics.

Key Differences Between Wet Molding and Dry Forming

Wet molding involves shaping bioplastic materials using a liquid resin combined with fibers or fillers, allowing for enhanced flexibility and detailed surface finishes. Dry forming, by contrast, utilizes dry bioplastic powders or granules compressed and heated to create solid forms, resulting in denser and more rigid products. Key differences lie in the processing methods, material consistency, and final product properties such as strength, texture, and moisture resistance.

Material Suitability: Wet Molding vs. Dry Forming for Bioplastics

Wet molding suits bioplastics that require enhanced plasticity and uniform dispersion of additives, such as starch-based composites, enabling smooth surface finishes and complex shapes. Dry forming is optimal for rigid bioplastics like polylactic acid (PLA) and cellulose fibers, providing higher dimensional stability and strength without solvent use. Material suitability depends on the bioplastic's moisture sensitivity and desired mechanical properties, with wet molding favoring flexible, moisture-compatible polymers and dry forming supporting structurally robust applications.

Process Workflow Comparison: Wet Molding and Dry Forming

Wet molding involves coating natural fibers or biopolymer resins with a liquid binder, followed by compression and curing to shape the material, resulting in enhanced fiber-matrix adhesion and improved mechanical strength. Dry forming uses dry fibers or powders that are mechanically pressed or compressed into molds without liquid binders, offering faster processing times and lower energy consumption but potentially weaker bonding. Comparing process workflows, wet molding requires additional steps of resin impregnation and curing, whereas dry forming streamlines production by eliminating wetting and drying phases, making it suitable for high-throughput manufacturing of bioplastic composites.

Energy Consumption in Wet Molding vs. Dry Forming Techniques

Wet molding techniques in bioplastic production typically consume more energy due to the need for drying and curing processes to remove moisture content. Dry forming methods generally require less energy as they involve shaping bioplastic materials without added water, eliminating extended drying times. Energy efficiency is a critical factor favoring dry forming when optimizing sustainable bioplastic manufacturing processes.

Environmental Impacts of Wet Molding and Dry Forming

Wet molding in bioplastic manufacturing generates higher water consumption and effluent discharge compared to dry forming, leading to increased wastewater treatment requirements and potential ecosystem contamination. Dry forming significantly reduces water usage and minimizes the release of harmful chemicals, resulting in a lower environmental footprint and improved sustainability. The energy consumption in dry forming is typically lower due to streamlined processing, contributing to reduced greenhouse gas emissions associated with bioplastic production.

Cost Efficiency Analysis: Wet Molding vs. Dry Forming

Wet molding often involves higher initial equipment and material costs due to the use of liquid bioplastics and curing processes, but it allows for complex shapes and thinner walls, potentially reducing material waste. Dry forming typically offers lower operational costs with simpler machinery and faster cycle times, enhancing cost efficiency for large-scale production with consistent, bulkier forms. Analyzing cost efficiency between wet molding and dry forming hinges on production volume, product complexity, and material utilization specific to bioplastic manufacturing.

Quality and Performance of Bioplastics: Wet vs. Dry Methods

Wet molding of bioplastics typically enhances material homogeneity and reduces internal stresses, resulting in improved mechanical strength and surface finish. Dry forming methods often lead to faster processing times but may introduce microstructural inconsistencies that affect durability and flexibility. The choice between wet and dry techniques directly impacts the bioplastics' tensile strength, biodegradability rates, and overall performance in end-use applications.

Industry Applications of Wet Molded and Dry Formed Bioplastics

Wet molding of bioplastics is widely used in automotive and aerospace industries for producing lightweight, complex-shaped components with enhanced mechanical properties and surface finish. Dry forming techniques dominate packaging and consumer goods sectors due to their efficiency in creating rigid, biodegradable containers and disposable cutlery that meet sustainability standards. Both methods leverage renewable biomass sources to reduce carbon footprint and promote circular economy practices in industrial manufacturing.

Future Trends in Bioplastic Manufacturing: Wet Molding and Dry Forming

Wet molding and dry forming represent pivotal methods in the evolving bioplastic manufacturing landscape, each offering unique advantages for sustainable production. Advancements in wet molding enhance the precision and structural integrity of bioplastic components by utilizing liquid biopolymer composites, while dry forming optimizes energy efficiency and material utilization through powder-based processes. Future trends emphasize integrating nanomaterials and bio-based additives to improve mechanical properties and biodegradability, positioning both methods at the forefront of eco-friendly innovation in bioplastic manufacturing.

Wet molding vs Dry forming Infographic

materialdif.com

materialdif.com