Oxodegradable plastics break down through exposure to oxygen and sunlight but often leave microplastic residues that can harm the environment. Compostable plastics decompose completely into non-toxic components under industrial composting conditions, supporting soil health and reducing pollution. Choosing compostable over oxodegradable bioplastics ensures a more sustainable and eco-friendly waste management process.

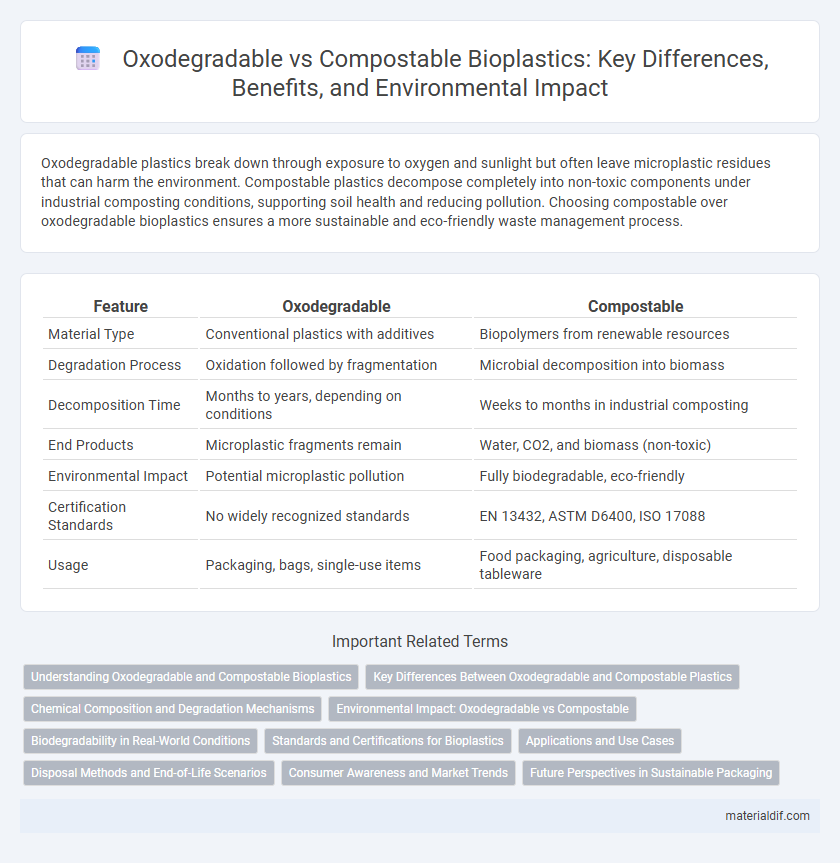

Table of Comparison

| Feature | Oxodegradable | Compostable |

|---|---|---|

| Material Type | Conventional plastics with additives | Biopolymers from renewable resources |

| Degradation Process | Oxidation followed by fragmentation | Microbial decomposition into biomass |

| Decomposition Time | Months to years, depending on conditions | Weeks to months in industrial composting |

| End Products | Microplastic fragments remain | Water, CO2, and biomass (non-toxic) |

| Environmental Impact | Potential microplastic pollution | Fully biodegradable, eco-friendly |

| Certification Standards | No widely recognized standards | EN 13432, ASTM D6400, ISO 17088 |

| Usage | Packaging, bags, single-use items | Food packaging, agriculture, disposable tableware |

Understanding Oxodegradable and Compostable Bioplastics

Oxodegradable bioplastics contain additives that accelerate plastic degradation through oxidation, breaking down into microplastics rather than fully biodegrading. Compostable bioplastics decompose entirely under industrial composting conditions, converting into carbon dioxide, water, and biomass without leaving harmful residues. Understanding these differences is crucial for proper waste management and environmental impact assessment of bioplastic materials.

Key Differences Between Oxodegradable and Compostable Plastics

Oxodegradable plastics break down through oxidation triggered by UV light or heat, resulting in fragmentation into microplastics without complete biodegradation, whereas compostable plastics fully biodegrade into organic matter under specific composting conditions. Compostable plastics comply with standards like ASTM D6400 or EN 13432, ensuring they decompose within a defined timeframe in industrial composting facilities, while oxodegradable plastics lack such certification and contribute to microplastic pollution. Key differences include their environmental impact, regulatory recognition, and degradation processes, making compostable plastics a preferred option for sustainable waste management.

Chemical Composition and Degradation Mechanisms

Oxodegradable plastics contain additives such as metal salts that promote fragmentation through oxidation under UV light and heat, breaking down the polymer chain into microplastics without fully mineralizing. Compostable plastics, primarily made from biopolymers like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), undergo enzymatic hydrolysis and microbial digestion, converting them into water, carbon dioxide, and biomass within industrial composting conditions. The chemical composition of oxodegradable plastics typically involves conventional polyethylene with pro-oxidant additives, while compostables rely on renewable, naturally derived polymers designed for complete biodegradation.

Environmental Impact: Oxodegradable vs Compostable

Oxodegradable plastics fragment into microplastics, posing long-term environmental risks by persisting in soil and marine ecosystems, whereas compostable plastics break down fully into non-toxic organic matter within 90 to 180 days under industrial composting conditions. Compostable bioplastics contribute to soil health by releasing nutrients and improving organic content, while oxodegradable variants may contribute to pollution due to incomplete degradation and microplastic accumulation. Lifecycle assessments highlight that compostable plastics offer a significantly lower environmental footprint and reduced greenhouse gas emissions compared to oxodegradable materials.

Biodegradability in Real-World Conditions

Oxodegradable plastics degrade through oxidation triggered by UV light and oxygen but often leave microplastics in the environment, limiting their complete biodegradability in real-world conditions. Compostable bioplastics break down fully into organic matter within industrial composting facilities, requiring specific temperature, humidity, and microbial activity to ensure efficient biodegradation. In natural environments such as soil or marine settings, compostable bioplastics degrade more reliably than oxodegradable plastics, which may persist and contribute to long-term pollution.

Standards and Certifications for Bioplastics

Oxodegradable bioplastics comply with standards such as ASTM D6954, which evaluates their oxidation and biodegradation within specific environments, but lack widespread certification for compostability. Compostable bioplastics adhere to recognized standards like ASTM D6400 and EN 13432, ensuring complete biodegradation and disintegration in industrial composting facilities within 90 to 180 days. Certifications from organizations like TUV Austria, BPI, and OK Compost validate that compostable bioplastics meet stringent criteria for environmental safety and performance.

Applications and Use Cases

Oxodegradable plastics are primarily used in applications requiring short-term durability, such as packaging films and agricultural mulch, where controlled fragmentation under UV exposure is beneficial. Compostable bioplastics are favored in food service items, organic waste bags, and disposable tableware due to their ability to biodegrade fully in industrial composting environments. Understanding these use cases helps industries select materials aligning with environmental goals and regulatory standards.

Disposal Methods and End-of-Life Scenarios

Oxodegradable plastics break down through oxidation when exposed to heat and oxygen, fragmenting into microplastics but not fully biodegrading, which complicates waste management and poses environmental risks. Compostable plastics decompose completely under industrial composting conditions, converting into water, carbon dioxide, and biomass, making them suitable for organic waste processing facilities. Effective disposal requires clear waste segregation to prevent contamination, ensuring compostable plastics reach composting sites while oxodegradables should be avoided in recycling or composting streams to minimize environmental impact.

Consumer Awareness and Market Trends

Consumer awareness regarding oxodegradable versus compostable bioplastics is increasing as market demand shifts toward truly sustainable solutions that degrade without leaving microplastic residues. Compostable bioplastics certified by standards such as ASTM D6400 and EN 13432 are gaining preference due to their verified ability to break down in industrial or home composting conditions. Market trends indicate a growing emphasis on clear labeling and education to help consumers distinguish between oxodegradable plastics, which fragment but do not fully biodegrade, and compostable alternatives that support circular economy goals.

Future Perspectives in Sustainable Packaging

Future perspectives in sustainable packaging emphasize the shift from oxodegradable to compostable materials due to environmental concerns and regulatory restrictions on oxodegradable plastics. Compostable bioplastics, certified under standards like ASTM D6400 and EN 13432, offer superior biodegradability and integration into existing organic waste systems. Innovations in biopolymer blends and improved industrial composting infrastructure are expected to drive wider adoption, enhancing circular economy models in packaging industries.

Oxodegradable vs Compostable Infographic

materialdif.com

materialdif.com