Mechanical recycling of bioplastic PET involves the physical process of grinding and remelting the material to produce new products, preserving its molecular structure and maintaining material quality. Organic recycling, or composting, breaks down bioplastic PET through microbial activity into natural elements like water, carbon dioxide, and biomass, reducing environmental impact without generating plastic waste. Choosing between mechanical and organic recycling depends on the specific properties of the bioplastic PET and the intended end-of-life solution, optimizing sustainability and resource efficiency.

Table of Comparison

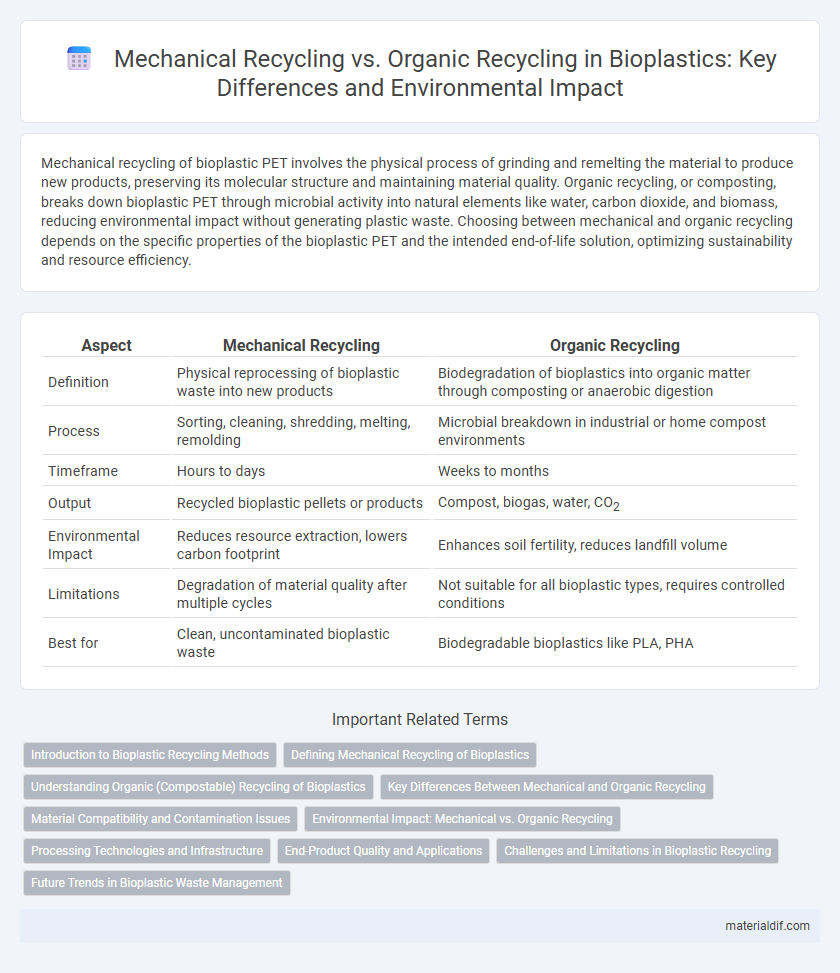

| Aspect | Mechanical Recycling | Organic Recycling |

|---|---|---|

| Definition | Physical reprocessing of bioplastic waste into new products | Biodegradation of bioplastics into organic matter through composting or anaerobic digestion |

| Process | Sorting, cleaning, shredding, melting, remolding | Microbial breakdown in industrial or home compost environments |

| Timeframe | Hours to days | Weeks to months |

| Output | Recycled bioplastic pellets or products | Compost, biogas, water, CO2 |

| Environmental Impact | Reduces resource extraction, lowers carbon footprint | Enhances soil fertility, reduces landfill volume |

| Limitations | Degradation of material quality after multiple cycles | Not suitable for all bioplastic types, requires controlled conditions |

| Best for | Clean, uncontaminated bioplastic waste | Biodegradable bioplastics like PLA, PHA |

Introduction to Bioplastic Recycling Methods

Mechanical recycling of bioplastics involves physically processing and re-melting materials like PLA and PHA to form new products, preserving polymer properties and reducing waste. Organic recycling, including industrial composting and anaerobic digestion, breaks down bioplastics into natural components such as water, carbon dioxide, and biomass under controlled microbial activity. Both methods enhance sustainable waste management by enabling bioplastic reuse or degradation, though compatibility varies based on material type and recycling infrastructure.

Defining Mechanical Recycling of Bioplastics

Mechanical recycling of bioplastics involves the physical processing of used bioplastic materials into new products without altering their chemical structure, preserving the polymer chains for reuse. This method typically includes sorting, grinding, washing, and melting the bioplastics to produce pellets for manufacturing new items. Mechanical recycling is an efficient way to reduce waste, lower production costs, and maintain material quality compared to organic recycling, which biodegrades bioplastics into natural compounds like water, carbon dioxide, and biomass.

Understanding Organic (Compostable) Recycling of Bioplastics

Organic recycling of bioplastics involves biodegradation through composting processes, where microorganisms convert compostable bioplastics into water, carbon dioxide, and biomass under controlled temperature, humidity, and oxygen conditions. Mechanical recycling, by contrast, focuses on physical reprocessing of plastic waste without chemical change, often unsuitable for compostable bioplastics due to material degradation. Compostable bioplastics require industrial composting facilities capable of maintaining temperatures above 58degC to ensure complete biodegradation within weeks, emphasizing the need to differentiate bioplastics by proper disposal pathways to optimize environmental benefits.

Key Differences Between Mechanical and Organic Recycling

Mechanical recycling of bioplastics involves shredding and melting the material to produce new plastic products, preserving polymer quality but requiring contamination-free inputs. Organic recycling, also known as composting or anaerobic digestion, breaks down bioplastics through microbial activity into water, carbon dioxide, and biomass, suitable for biodegradable materials but ineffective for conventional plastics. Key differences include the recyclate quality, environmental conditions required, and types of bioplastics compatible with each method, with mechanical recycling favoring PET-based bioplastics and organic recycling suitable for PLA and starch-based polymers.

Material Compatibility and Contamination Issues

Mechanical recycling of bioplastics faces challenges in material compatibility due to varying polymer compositions, which can cause contamination and degrade the quality of recycled output. Organic recycling, including composting and anaerobic digestion, better accommodates biodegradable bioplastics by breaking down materials chemically, avoiding cross-contamination with non-biodegradable plastics. Effective separation and proper sorting are crucial to minimize contamination and ensure optimal recycling performance for both mechanical and organic processes.

Environmental Impact: Mechanical vs. Organic Recycling

Mechanical recycling of bioplastics significantly reduces greenhouse gas emissions by preserving polymer quality and minimizing energy consumption compared to producing new materials. Organic recycling, such as composting or anaerobic digestion, enables bioplastics to biodegrade into carbon dioxide, methane, and biomass, thereby closing the carbon loop but requires controlled conditions to avoid methane leakage. Evaluating environmental impact, mechanical recycling excels in resource efficiency and emissions reduction, while organic recycling effectively returns carbon to the ecosystem but may generate methane, a potent greenhouse gas.

Processing Technologies and Infrastructure

Mechanical recycling of bioplastics involves physical processes such as shredding, melting, and remolding, which require established industrial facilities with sorting and contamination control systems to maintain material quality. Organic recycling, including composting and anaerobic digestion, relies on biological decomposition in specialized reactors or composting sites that demand controlled temperature, humidity, and microbial activity to break down biodegradable polymers effectively. Infrastructure for mechanical recycling is widespread but often limited by polymer type compatibility, whereas organic recycling infrastructure is expanding in regions with stringent waste management policies but still faces challenges in scalability and contamination of non-compostable plastics.

End-Product Quality and Applications

Mechanical recycling of bioplastics preserves polymer integrity, resulting in high-quality end products suitable for manufacturing durable goods, automotive parts, and consumer electronics. Organic recycling, such as composting, breaks down bioplastics into biomass, CO2, and water, producing nutrient-rich compost ideal for agriculture and landscaping but unsuitable for material reuse. Mechanical recycling supports circular economy goals by enabling multiple cycles of product use, whereas organic recycling facilitates waste biodegradation but limits applications to soil enhancement.

Challenges and Limitations in Bioplastic Recycling

Mechanical recycling of bioplastics faces challenges such as material contamination, degradation of polymer quality, and limited recycling cycles, which reduce the efficiency of reprocessing. Organic recycling, including composting and anaerobic digestion, is constrained by the need for specific environmental conditions, slow biodegradation rates for certain bioplastic types, and potential release of methane during anaerobic processes. Both methods struggle with a lack of standardized sorting systems and inadequate infrastructure, hindering large-scale, effective bioplastic waste management.

Future Trends in Bioplastic Waste Management

Mechanical recycling of bioplastics involves physically processing materials to retain polymer properties, enabling repeated reuse with lower energy consumption. Organic recycling, such as composting and anaerobic digestion, breaks bioplastics down into natural compounds, supporting circular bioeconomy goals by returning nutrients to soil or generating biogas. Future trends emphasize integrating hybrid recycling systems and advanced sorting technologies to optimize recovery rates, reduce contamination, and support sustainable bioplastic waste management.

Mechanical recycling vs Organic recycling Infographic

materialdif.com

materialdif.com