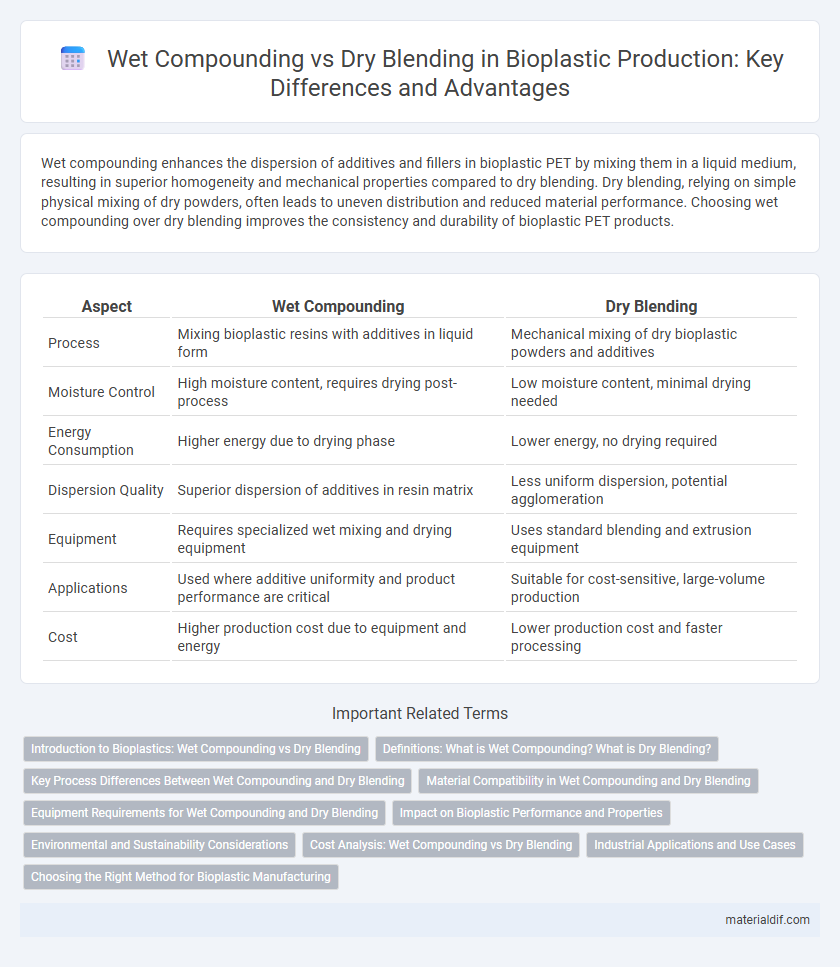

Wet compounding enhances the dispersion of additives and fillers in bioplastic PET by mixing them in a liquid medium, resulting in superior homogeneity and mechanical properties compared to dry blending. Dry blending, relying on simple physical mixing of dry powders, often leads to uneven distribution and reduced material performance. Choosing wet compounding over dry blending improves the consistency and durability of bioplastic PET products.

Table of Comparison

| Aspect | Wet Compounding | Dry Blending |

|---|---|---|

| Process | Mixing bioplastic resins with additives in liquid form | Mechanical mixing of dry bioplastic powders and additives |

| Moisture Control | High moisture content, requires drying post-process | Low moisture content, minimal drying needed |

| Energy Consumption | Higher energy due to drying phase | Lower energy, no drying required |

| Dispersion Quality | Superior dispersion of additives in resin matrix | Less uniform dispersion, potential agglomeration |

| Equipment | Requires specialized wet mixing and drying equipment | Uses standard blending and extrusion equipment |

| Applications | Used where additive uniformity and product performance are critical | Suitable for cost-sensitive, large-volume production |

| Cost | Higher production cost due to equipment and energy | Lower production cost and faster processing |

Introduction to Bioplastics: Wet Compounding vs Dry Blending

Wet compounding involves mixing bioplastic polymers with additives and fillers in a molten state, enhancing dispersion and improving material properties such as flexibility and strength. Dry blending, on the other hand, combines powdered bioplastic resins and additives at ambient temperature before melt processing, offering a simpler, more cost-effective approach but with potential challenges in homogeneity. Selecting the optimal method depends on the desired application performance, processing equipment, and product specifications within the bioplastics industry.

Definitions: What is Wet Compounding? What is Dry Blending?

Wet compounding involves mixing bioplastic pellets with additives in a liquid medium to achieve homogeneous dispersion and enhance material properties before drying and pelletizing. Dry blending refers to the physical mixing of bioplastic powders or pellets with additives in their dry form without the use of solvents or liquids, preserving the original material properties while simplifying processing. Both techniques impact the performance, processing efficiency, and final characteristics of bioplastic products depending on formulation requirements and manufacturing conditions.

Key Process Differences Between Wet Compounding and Dry Blending

Wet compounding integrates bioplastic polymers with additives in a liquid medium, enhancing dispersion and reducing thermal degradation compared to dry blending. Dry blending involves physically mixing powdered components without solvents, which can lead to heterogeneous distribution and limited interaction between materials. Key differences include the improved homogeneity and controlled particle size in wet compounding versus the faster, more energy-efficient process but potential inconsistencies in dry blending.

Material Compatibility in Wet Compounding and Dry Blending

Wet compounding enhances material compatibility by allowing bioplastic polymers to be uniformly dispersed in a liquid medium, improving filler distribution and reducing agglomeration. Dry blending relies on mechanical mixing of powder components, which can result in poor dispersion and weaker interfacial bonding between bioplastic matrix and additives. The superior material compatibility achieved through wet compounding leads to improved composite properties such as tensile strength, impact resistance, and biodegradability.

Equipment Requirements for Wet Compounding and Dry Blending

Wet compounding of bioplastics requires specialized equipment such as high-shear mixers, twin-screw extruders with liquid feeding systems, and efficient drying units to handle the moisture content and ensure uniform dispersion of additives. Dry blending utilizes simpler equipment like ribbon blenders, tumbling mixers, and conventional single or twin-screw extruders without the need for liquid injection systems. The choice between wet compounding and dry blending significantly impacts production costs, equipment investment, and material quality consistency in bioplastic manufacturing.

Impact on Bioplastic Performance and Properties

Wet compounding enhances bioplastic performance by promoting better dispersion of fillers and additives, resulting in improved mechanical strength and uniformity. Dry blending may lead to incomplete mixing, causing weak points and reduced thermal stability in bioplastic products. Optimizing compounding methods directly influences biodegradability, tensile properties, and processing efficiency in bioplastic manufacturing.

Environmental and Sustainability Considerations

Wet compounding reduces energy consumption by eliminating the drying step, lowering greenhouse gas emissions compared to dry blending. Dry blending can increase plastic waste through the incorporation of incompatible materials, while wet compounding enhances material homogeneity, improving biodegradability and recyclability. Selecting wet compounding supports sustainable bioplastic manufacturing by minimizing resource use and promoting environmentally friendly processing.

Cost Analysis: Wet Compounding vs Dry Blending

Wet compounding generally incurs higher initial costs due to additional equipment and energy consumption, but can enhance polymer dispersion and reduce processing times, resulting in potential long-term savings. Dry blending offers lower upfront expenses and simpler processing but may lead to inferior material homogeneity and increased defects, impacting overall product quality and lifecycle cost. Cost analysis must weigh equipment investment, operational efficiency, product performance, and waste generation specific to bioplastic formulations.

Industrial Applications and Use Cases

Wet compounding enhances the dispersion of additives and fillers in bioplastics, improving mechanical properties and processability for applications like automotive parts and packaging films. Dry blending offers simpler processing and cost-efficiency, suitable for large-scale production of biodegradable bags and agricultural mulch films. Industrial use favors wet compounding when precise additive integration is critical for high-performance bioplastic components.

Choosing the Right Method for Bioplastic Manufacturing

Wet compounding enhances bioplastic manufacturing by improving dispersion of additives and fillers, resulting in superior mechanical properties and homogeneity. Dry blending offers cost-effectiveness and simplicity, but may lead to inconsistent material distribution and lower performance. Selecting the appropriate method depends on the desired product quality, processing efficiency, and specific application requirements in bioplastic production.

Wet compounding vs Dry blending Infographic

materialdif.com

materialdif.com