PHA granules, derived from microbial fermentation, offer superior biodegradability and are fully compostable in marine environments, unlike PLA pellets which require industrial composting conditions. PHA's durability and flexibility make it ideal for packaging and single-use products, whereas PLA, sourced from plant starch, tends to be more brittle and less heat resistant. Choosing PHA over PLA enhances environmental sustainability due to its natural breakdown process and lower ecological footprint.

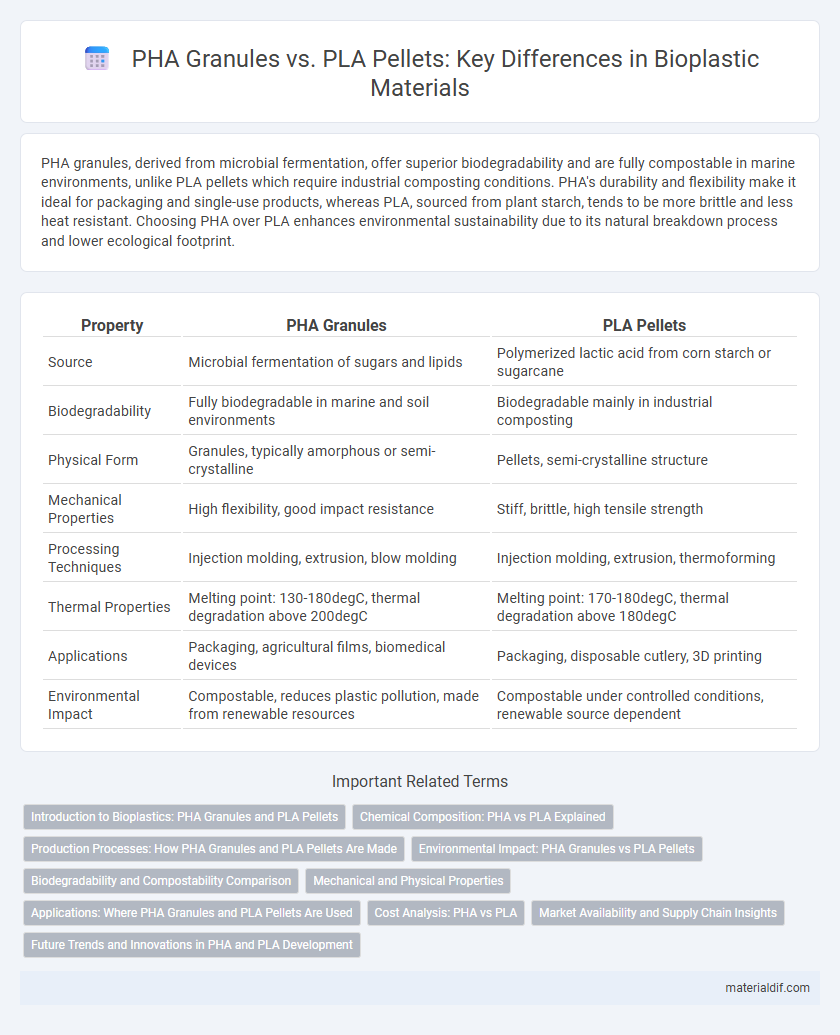

Table of Comparison

| Property | PHA Granules | PLA Pellets |

|---|---|---|

| Source | Microbial fermentation of sugars and lipids | Polymerized lactic acid from corn starch or sugarcane |

| Biodegradability | Fully biodegradable in marine and soil environments | Biodegradable mainly in industrial composting |

| Physical Form | Granules, typically amorphous or semi-crystalline | Pellets, semi-crystalline structure |

| Mechanical Properties | High flexibility, good impact resistance | Stiff, brittle, high tensile strength |

| Processing Techniques | Injection molding, extrusion, blow molding | Injection molding, extrusion, thermoforming |

| Thermal Properties | Melting point: 130-180degC, thermal degradation above 200degC | Melting point: 170-180degC, thermal degradation above 180degC |

| Applications | Packaging, agricultural films, biomedical devices | Packaging, disposable cutlery, 3D printing |

| Environmental Impact | Compostable, reduces plastic pollution, made from renewable resources | Compostable under controlled conditions, renewable source dependent |

Introduction to Bioplastics: PHA Granules and PLA Pellets

PHA granules and PLA pellets represent two prominent forms of bioplastics distinguished by their chemical composition and biodegradability. PHA granules are polyhydroxyalkanoates produced by microbial fermentation, known for their complete biodegradability in various environments including marine settings. PLA pellets, derived from fermented plant starch such as corn, offer high strength and transparency but require industrial composting for efficient degradation.

Chemical Composition: PHA vs PLA Explained

PHA granules consist of polyhydroxyalkanoates, a family of biopolyesters produced naturally through microbial fermentation of carbon sources, characterized by hydroxy acid monomers with varying side chains that influence biodegradability and mechanical properties. PLA pellets are composed of polylactic acid, a synthetic aliphatic polyester derived from polymerized lactic acid, primarily formed through ring-opening polymerization of lactide with a uniform lactic acid monomer structure providing stiffness and transparency. The chemical composition differences impact thermal stability, crystallinity, and degradation rates, with PHA's diverse monomeric units offering greater flexibility and biodegradability compared to the more rigid, plant-based PLA.

Production Processes: How PHA Granules and PLA Pellets Are Made

PHA granules are produced through bacterial fermentation, where microorganisms convert carbon sources into polyhydroxyalkanoates stored intracellularly as granules, subsequently extracted and purified. PLA pellets are synthesized via ring-opening polymerization of lactide, derived from the fermentation of renewable resources like corn starch or sugarcane, followed by pelletizing into small granules for industrial use. The microbial process for PHA is bio-based and intracellular, while PLA production involves chemical polymerization with bio-derived monomers.

Environmental Impact: PHA Granules vs PLA Pellets

PHA granules exhibit superior environmental benefits compared to PLA pellets due to their complete biodegradability in marine and soil environments, reducing persistent plastic pollution. PLA pellets, derived from corn starch, require industrial composting facilities for effective breakdown, limiting their environmental compatibility. The carbon footprint of PHA production is generally lower, as it can be synthesized from renewable waste substrates, enhancing sustainability in bioplastic applications.

Biodegradability and Compostability Comparison

PHA granules exhibit superior biodegradability compared to PLA pellets, as they naturally break down in various environmental conditions, including marine and soil ecosystems, within weeks to months. PLA pellets require industrial composting facilities with high temperatures and controlled humidity to achieve effective compostability, often taking several months to decompose. The microbial assimilation process of PHA granules results in complete mineralization without toxic residues, whereas PLA pellets may leave behind microplastic fragments if composting conditions are suboptimal.

Mechanical and Physical Properties

PHA granules exhibit higher biodegradability and better flexibility compared to PLA pellets, making them suitable for applications requiring durable yet eco-friendly materials. PLA pellets generally offer greater tensile strength and stiffness, with higher melting points that favor heat-resistant manufacturing processes. Both materials provide distinct mechanical and physical properties, influencing their selection based on product performance demands and environmental impact considerations.

Applications: Where PHA Granules and PLA Pellets Are Used

PHA granules are widely used in medical applications such as sutures, drug delivery systems, and tissue engineering due to their biocompatibility and biodegradability. PLA pellets find extensive use in packaging, disposable tableware, and 3D printing because of their rigidity and ease of processing. Both materials serve as sustainable alternatives in agriculture, with PHA granules favored for controlled-release fertilizers and PLA pellets for biodegradable mulch films.

Cost Analysis: PHA vs PLA

PHA granules typically incur higher production costs than PLA pellets due to more complex microbial fermentation and extraction processes. PLA benefits from abundant feedstock like corn starch and well-established manufacturing infrastructure, reducing its overall market price. Cost competitiveness of PHA is improving with advances in biotechnology, but PLA remains the economically preferred option for large-scale applications.

Market Availability and Supply Chain Insights

PHA granules exhibit increasing market availability driven by sustainable production methods and rising demand for biodegradable plastics in packaging and agriculture sectors. PLA pellets dominate the supply chain with established global production networks, offering consistent quality and cost efficiency in consumer goods and medical applications. Supply chain insights highlight PHA's reliance on fermentation-based feedstocks, causing variability, while PLA benefits from bio-based polymerization processes using abundant corn starch, ensuring scalable supply.

Future Trends and Innovations in PHA and PLA Development

Future trends in bioplastic development highlight enhanced biodegradability and sustainability of PHA granules compared to conventional PLA pellets, driven by advances in microbial fermentation technology and feedstock diversification. Innovations include engineered PHA variants with improved mechanical properties and tailored degradation rates, while PLA research focuses on blending techniques and biocomposite formulations to overcome brittleness and thermal limitations. Both PHA and PLA industries are converging towards circular economy models through improved recycling methods and integration with bio-based additives to increase performance in packaging and medical applications.

PHA granules vs PLA pellets Infographic

materialdif.com

materialdif.com