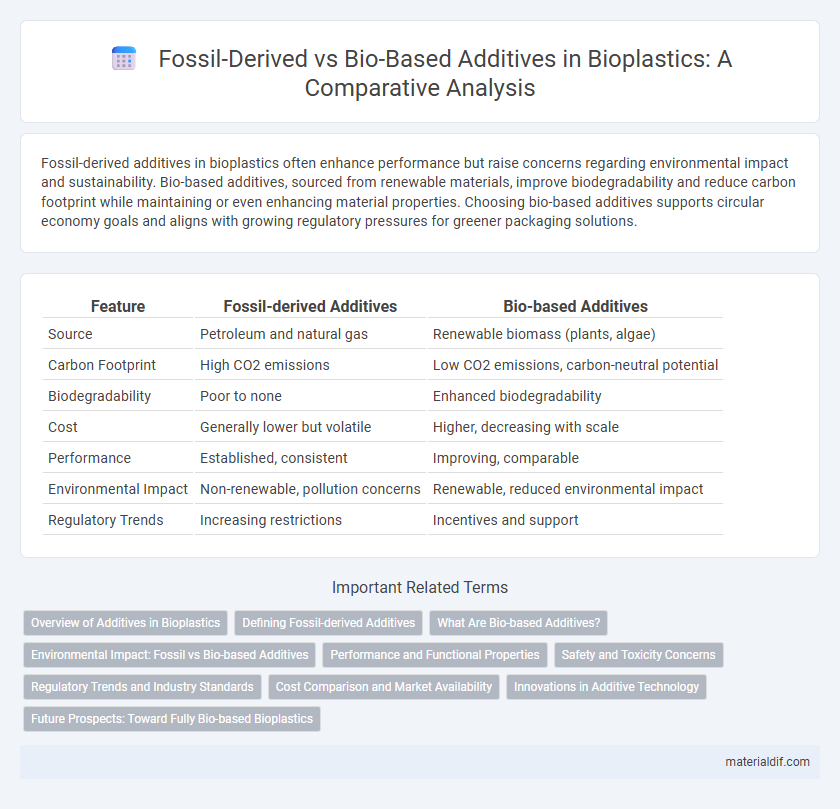

Fossil-derived additives in bioplastics often enhance performance but raise concerns regarding environmental impact and sustainability. Bio-based additives, sourced from renewable materials, improve biodegradability and reduce carbon footprint while maintaining or even enhancing material properties. Choosing bio-based additives supports circular economy goals and aligns with growing regulatory pressures for greener packaging solutions.

Table of Comparison

| Feature | Fossil-derived Additives | Bio-based Additives |

|---|---|---|

| Source | Petroleum and natural gas | Renewable biomass (plants, algae) |

| Carbon Footprint | High CO2 emissions | Low CO2 emissions, carbon-neutral potential |

| Biodegradability | Poor to none | Enhanced biodegradability |

| Cost | Generally lower but volatile | Higher, decreasing with scale |

| Performance | Established, consistent | Improving, comparable |

| Environmental Impact | Non-renewable, pollution concerns | Renewable, reduced environmental impact |

| Regulatory Trends | Increasing restrictions | Incentives and support |

Overview of Additives in Bioplastics

Additives in bioplastics play a crucial role in enhancing material properties such as flexibility, durability, and thermal stability. Fossil-derived additives, including plasticizers, stabilizers, and flame retardants, are traditionally used but raise environmental concerns due to their non-renewable origin and potential toxicity. Bio-based additives, sourced from renewable materials like plant oils, lignin, and natural fibers, offer improved biodegradability and reduced ecological impact, aligning with sustainability goals in bioplastic production.

Defining Fossil-derived Additives

Fossil-derived additives are chemical compounds sourced from non-renewable petroleum-based materials, commonly used to enhance the properties of bioplastics such as flexibility, durability, and UV resistance. These additives typically include plasticizers, stabilizers, and flame retardants that originate from fossil fuels, impacting the environmental footprint of bioplastic products. The reliance on fossil-derived additives raises concerns about biodegradability and sustainability compared to bio-based additives derived from renewable resources like plant oils or starches.

What Are Bio-based Additives?

Bio-based additives are derived from renewable biological sources such as plant oils, starches, and natural fibers, enhancing the biodegradability and environmental compatibility of bioplastics. These additives improve properties like flexibility, durability, and processing efficiency without relying on fossil-derived chemicals. Using bio-based additives reduces carbon footprint and supports a sustainable plastics industry aligned with circular economy principles.

Environmental Impact: Fossil vs Bio-based Additives

Fossil-derived additives in bioplastics contribute to higher carbon emissions and long-term environmental pollution due to their non-renewable origin and toxic degradation products. Bio-based additives, sourced from renewable biomass, enhance biodegradability and reduce the carbon footprint by promoting circular economy principles and lowering reliance on fossil fuels. Life cycle assessments consistently show bio-based additives significantly decrease environmental impact across resource extraction, production, and end-of-life disposal stages compared to fossil-derived alternatives.

Performance and Functional Properties

Fossil-derived additives in bioplastics often enhance mechanical strength, thermal stability, and barrier properties but pose sustainability and toxicity concerns. Bio-based additives provide comparable functional properties such as biodegradability, UV resistance, and flexibility while reducing environmental impact and improving compostability. Optimizing additive selection based on specific performance requirements enables development of bioplastics with tailored durability and eco-friendly characteristics.

Safety and Toxicity Concerns

Fossil-derived additives in bioplastics often raise safety and toxicity concerns due to the presence of hazardous chemicals and potential leaching of harmful substances during degradation. Bio-based additives, sourced from renewable materials, typically exhibit lower toxicity and reduced environmental impact, enhancing the overall safety profile of bioplastic products. Regulatory agencies increasingly favor bio-based additives to minimize health risks and promote sustainable alternatives in bioplastic formulations.

Regulatory Trends and Industry Standards

Regulatory trends increasingly favor bio-based additives in bioplastics due to stricter environmental policies targeting fossil-derived materials, driving innovation toward sustainable formulations. Industry standards like ASTM D6866 and ISO 16620 promote transparency in carbon content, encouraging adoption of renewable additives to improve bioplastic biodegradability and lifecycle impact. Compliance with emerging EU and US regulations, such as the European Green Deal and the FDA's guidance on bioplastics, underscores the shift towards bio-based additives to meet sustainability benchmarks and market demands.

Cost Comparison and Market Availability

Fossil-derived additives for bioplastics generally offer lower upfront costs due to established production infrastructure but face price volatility linked to crude oil markets. Bio-based additives tend to have higher initial prices driven by limited supply and emerging technologies, yet increasing consumer demand and regulatory incentives are expanding their market availability. The cost gap is gradually narrowing as scale-up in bio-based additive manufacturing enhances competitiveness and supply chain resilience.

Innovations in Additive Technology

Innovations in additive technology have advanced the development of bio-based additives that enhance the performance and biodegradability of bioplastics while reducing reliance on fossil-derived additives. These bio-based additives, often derived from renewable resources like plant oils, lignin, and starch, improve properties such as flexibility, UV resistance, and thermal stability in bioplastic formulations. Emerging research focuses on functionalizing bio-based additives to match or exceed the effectiveness of traditional fossil-derived counterparts, promoting sustainable packaging and reducing environmental impact.

Future Prospects: Toward Fully Bio-based Bioplastics

Fossil-derived additives currently dominate bioplastic formulations due to their cost-effectiveness and established supply chains, but they contribute to carbon emissions and limit sustainability goals. Bio-based additives, sourced from renewable materials like vegetable oils and lignin, offer enhanced biodegradability and reduced environmental impact, driving innovation in fully bio-based bioplastics. Future prospects emphasize developing scalable, high-performance bio-additives to replace petrochemical counterparts, enabling a circular economy and advancing global carbon neutrality targets.

Fossil-derived Additives vs Bio-based Additives Infographic

materialdif.com

materialdif.com