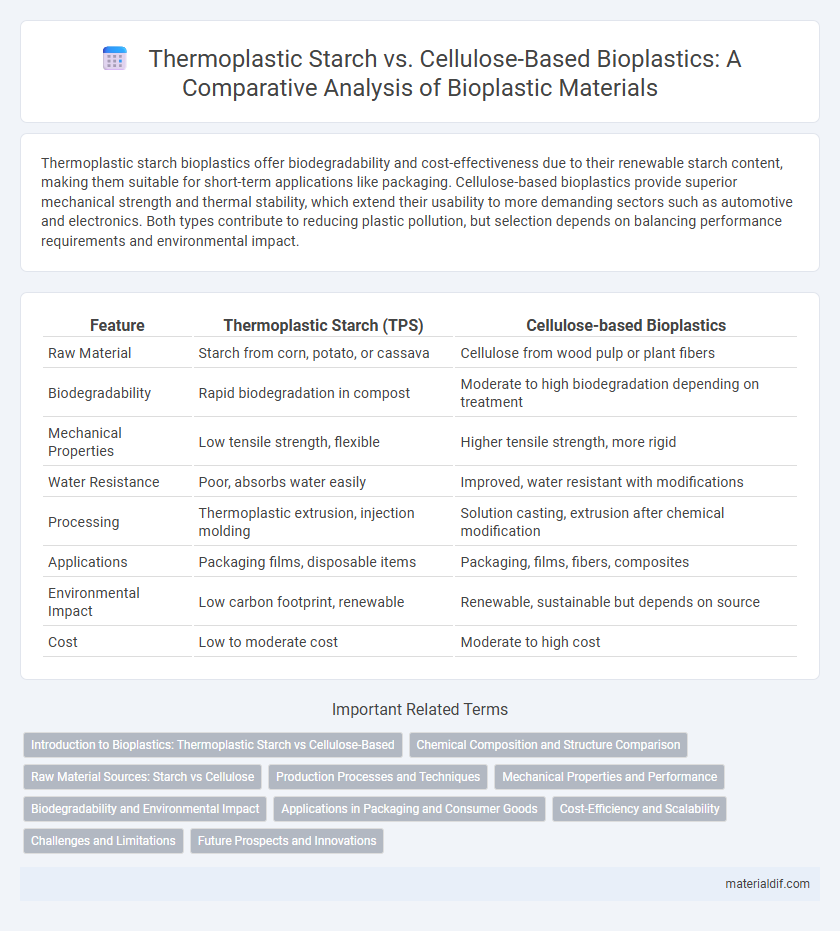

Thermoplastic starch bioplastics offer biodegradability and cost-effectiveness due to their renewable starch content, making them suitable for short-term applications like packaging. Cellulose-based bioplastics provide superior mechanical strength and thermal stability, which extend their usability to more demanding sectors such as automotive and electronics. Both types contribute to reducing plastic pollution, but selection depends on balancing performance requirements and environmental impact.

Table of Comparison

| Feature | Thermoplastic Starch (TPS) | Cellulose-based Bioplastics |

|---|---|---|

| Raw Material | Starch from corn, potato, or cassava | Cellulose from wood pulp or plant fibers |

| Biodegradability | Rapid biodegradation in compost | Moderate to high biodegradation depending on treatment |

| Mechanical Properties | Low tensile strength, flexible | Higher tensile strength, more rigid |

| Water Resistance | Poor, absorbs water easily | Improved, water resistant with modifications |

| Processing | Thermoplastic extrusion, injection molding | Solution casting, extrusion after chemical modification |

| Applications | Packaging films, disposable items | Packaging, films, fibers, composites |

| Environmental Impact | Low carbon footprint, renewable | Renewable, sustainable but depends on source |

| Cost | Low to moderate cost | Moderate to high cost |

Introduction to Bioplastics: Thermoplastic Starch vs Cellulose-Based

Thermoplastic starch (TPS) and cellulose-based bioplastics represent two prominent categories in sustainable materials derived from renewable biomass. TPS is produced by plasticizing starch with water or other plasticizers, resulting in a biodegradable polymer with applications in packaging and disposable items. Cellulose-based bioplastics harness cellulose fibers or derivatives, offering enhanced mechanical strength, moisture resistance, and biodegradability, making them suitable for more durable bioplastic products.

Chemical Composition and Structure Comparison

Thermoplastic starch (TPS) consists primarily of amylose and amylopectin polymers derived from plant starch, which are plasticized to form a flexible matrix, while cellulose-based bioplastics are composed of linear chains of b-D-glucose units linked by b-1,4-glycosidic bonds, creating a highly crystalline and rigid structure. The branched architecture of TPS allows for greater processability and biodegradability, whereas the extensive hydrogen bonding in cellulose imparts superior mechanical strength and thermal stability. Chemical modifications such as esterification or etherification are often applied to cellulose to enhance its compatibility and versatility compared to the inherently hydrophilic starch-based polymers.

Raw Material Sources: Starch vs Cellulose

Thermoplastic starch bioplastics are derived from abundant agricultural crops such as corn, potatoes, and cassava, utilizing starch as the primary raw material, which is renewable and biodegradable. Cellulose-based bioplastics, on the other hand, are sourced from the fibrous cell walls of plants, including wood, cotton, and agricultural residues, providing a sustainable and widely available raw material with high structural integrity. The choice between starch and cellulose impacts the biodegradability, mechanical properties, and lifecycle sustainability of the resulting bioplastic products.

Production Processes and Techniques

Thermoplastic starch is produced by gelatinizing starch with plasticizers such as glycerol or sorbitol under heat and shear, enabling it to be processed via conventional thermoplastic techniques like extrusion and injection molding. Cellulose-based bioplastics involve extracting cellulose fibers from sources such as wood, agricultural residues, or cotton, followed by chemical modification or blending with polymers to improve processability and material properties. Both materials offer sustainable alternatives, but cellulose bioplastics typically require more complex chemical treatments compared to the simpler, cost-effective starch gelatinization method used in thermoplastic starch production.

Mechanical Properties and Performance

Thermoplastic starch (TPS) bioplastics exhibit moderate tensile strength and flexibility but often suffer from poor moisture resistance and lower durability, limiting their use in high-performance applications. Cellulose-based bioplastics demonstrate superior mechanical properties, including higher tensile strength, stiffness, and better thermal stability, making them more suitable for packaging and structural materials. The enhanced crystallinity and hydrogen bonding in cellulose bioplastics contribute to their improved mechanical performance compared to TPS.

Biodegradability and Environmental Impact

Thermoplastic starch bioplastics exhibit rapid biodegradability due to their natural polysaccharide content, breaking down efficiently in soil and marine environments within weeks. Cellulose-based bioplastics also biodegrade effectively but at a slower rate, offering enhanced mechanical strength and durability that extend their lifecycle before decomposition. Both materials significantly reduce environmental impact compared to conventional plastics, with thermoplastic starch favoring quick compostability and cellulose-based options supporting sustainable long-term performance.

Applications in Packaging and Consumer Goods

Thermoplastic starch excels in flexible packaging applications due to its biodegradability and cost-effectiveness, making it ideal for bags, wraps, and loose-fill packaging. Cellulose-based bioplastics offer superior mechanical strength and moisture resistance, which suit rigid packaging and durable consumer goods like containers and trays. Both materials address sustainability demands, with thermoplastic starch favored for short-life packaging and cellulose-based bioplastics suited for longer-lasting products.

Cost-Efficiency and Scalability

Thermoplastic starch (TPS) offers significant cost-efficiency due to its abundant, low-cost raw material--corn or potato starch--and straightforward processing techniques compatible with existing plastic manufacturing equipment. Cellulose-based bioplastics, derived from plant fiber, face higher production costs and more complex processing, limiting their current scalability despite superior mechanical properties. TPS scalability benefits from established agricultural supply chains and rapid biodegradation rates, while cellulose-based bioplastics require advancements in extraction and modification technologies to reach comparable commercial volume.

Challenges and Limitations

Thermoplastic starch faces challenges such as high water sensitivity and poor mechanical strength, limiting its use in moisture-prone applications and demanding plasticizer additives to improve flexibility. Cellulose-based bioplastics struggle with complex extraction and costly processing, affecting large-scale production feasibility and requiring advanced chemical treatments to enhance biodegradability and performance. Both types encounter limitations in thermal stability and barrier properties, hindering their suitability for diverse packaging and industrial uses.

Future Prospects and Innovations

Thermoplastic starch (TPS) offers significant potential due to its biodegradability and cost-effectiveness, making it suitable for packaging and single-use applications, while ongoing innovations aim to enhance its water resistance and mechanical properties. Cellulose-based bioplastics show promise for future applications with their superior strength, biodegradability, and compatibility with existing recycling systems, driven by advancements in nanocellulose and chemical modification techniques. Both materials benefit from research focused on improving scalability, durability, and environmental impact, positioning them as key players in sustainable bioplastic development.

Thermoplastic starch vs Cellulose-based bioplastics Infographic

materialdif.com

materialdif.com