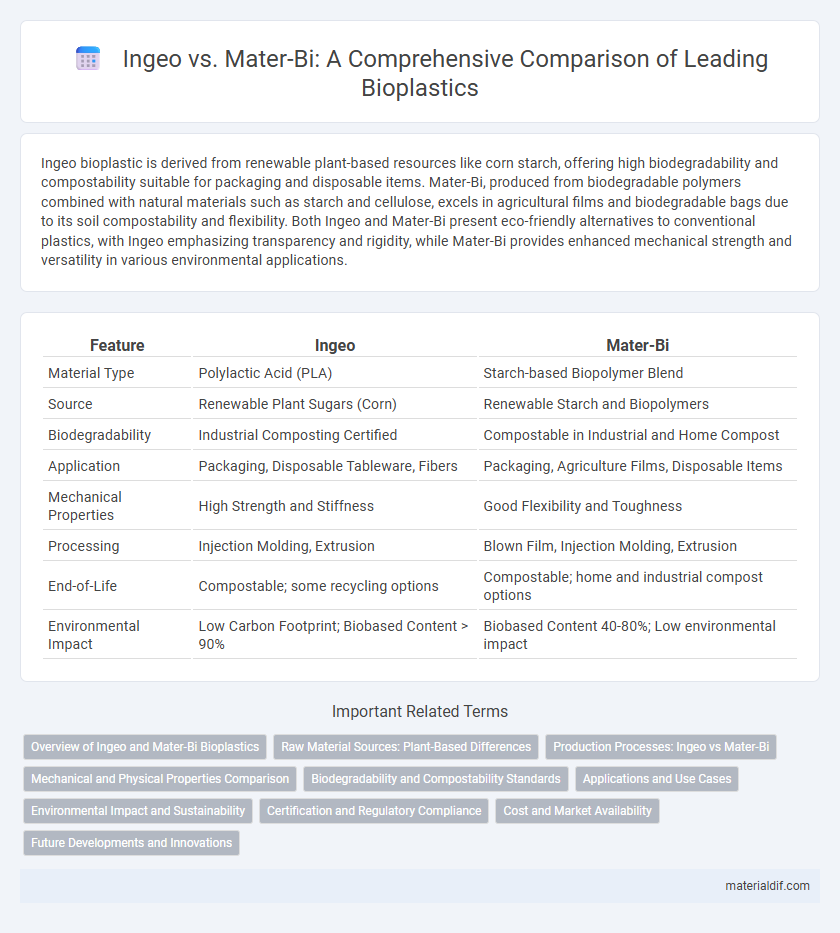

Ingeo bioplastic is derived from renewable plant-based resources like corn starch, offering high biodegradability and compostability suitable for packaging and disposable items. Mater-Bi, produced from biodegradable polymers combined with natural materials such as starch and cellulose, excels in agricultural films and biodegradable bags due to its soil compostability and flexibility. Both Ingeo and Mater-Bi present eco-friendly alternatives to conventional plastics, with Ingeo emphasizing transparency and rigidity, while Mater-Bi provides enhanced mechanical strength and versatility in various environmental applications.

Table of Comparison

| Feature | Ingeo | Mater-Bi |

|---|---|---|

| Material Type | Polylactic Acid (PLA) | Starch-based Biopolymer Blend |

| Source | Renewable Plant Sugars (Corn) | Renewable Starch and Biopolymers |

| Biodegradability | Industrial Composting Certified | Compostable in Industrial and Home Compost |

| Application | Packaging, Disposable Tableware, Fibers | Packaging, Agriculture Films, Disposable Items |

| Mechanical Properties | High Strength and Stiffness | Good Flexibility and Toughness |

| Processing | Injection Molding, Extrusion | Blown Film, Injection Molding, Extrusion |

| End-of-Life | Compostable; some recycling options | Compostable; home and industrial compost options |

| Environmental Impact | Low Carbon Footprint; Biobased Content > 90% | Biobased Content 40-80%; Low environmental impact |

Overview of Ingeo and Mater-Bi Bioplastics

Ingeo bioplastic, derived from renewable plant starch such as corn, offers compostability and a lower carbon footprint, making it ideal for packaging and disposable items. Mater-Bi, a family of bioplastics produced from biodegradable starches and biopolymers, excels in agricultural films and compostable bags due to its high biodegradability and flexibility. Both Ingeo and Mater-Bi contribute to sustainable alternatives by reducing reliance on fossil fuels and enhancing end-of-life options through industrial composting.

Raw Material Sources: Plant-Based Differences

Ingeo is derived primarily from fermented plant sugars, mainly corn starch, making it a polylactic acid (PLA) bioplastic with high purity and consistent sugar content. Mater-Bi is a blend of biodegradable polymers sourced from corn starch, cellulose, and other plant-based materials like tapioca or potato starch, offering more variability in raw inputs. These distinctions influence their biodegradability, mechanical properties, and compostability, with Ingeo often used for clear packaging and Mater-Bi favored in flexible applications such as bags and films.

Production Processes: Ingeo vs Mater-Bi

Ingeo is produced through the fermentation of plant sugars to create polylactic acid (PLA), utilizing a biochemical process that converts renewable resources like corn starch into biodegradable polymers. Mater-Bi, in contrast, is synthesized from a blend of starches, cellulose, and biodegradable polyesters via extrusion and compounding techniques, tailored for enhanced compostability and mechanical properties. The distinct production methods result in Ingeo offering greater transparency and stiffness, while Mater-Bi provides superior flexibility and biodegradability in various environmental conditions.

Mechanical and Physical Properties Comparison

Ingeo bioplastic, derived from polylactic acid (PLA), exhibits high tensile strength and stiffness but tends to have lower impact resistance and limited flexibility compared to Mater-Bi. Mater-Bi, a starch-based bioplastic blend, offers superior elongation at break and better impact resistance, making it more suitable for applications requiring flexibility and durability. Both materials demonstrate good biodegradability, but Ingeo provides a smoother surface finish and higher clarity due to its crystalline structure, while Mater-Bi offers enhanced moisture resistance and compostability under various conditions.

Biodegradability and Compostability Standards

Ingeo bioplastics are certified compostable under ASTM D6400 and EN 13432 standards, ensuring complete biodegradability within industrial composting facilities typically within 90 to 180 days. Mater-Bi bioplastics exceed these benchmarks by being both home and industrial compostable, meeting the more rigorous UNI EN 17427 standard for home composting and ISO 14855 for biodegradability. The enhanced compostability of Mater-Bi provides broader environmental benefits by decomposing in natural settings without leaving toxic residues, compared to Ingeo's reliance on controlled composting environments.

Applications and Use Cases

Ingeo bioplastic, derived from renewable plant sugars, is widely used in packaging, food serviceware, and textiles due to its compostability and high clarity, making it ideal for single-use items and sustainable fashion. Mater-Bi, a starch-based bioplastic, excels in agricultural films, compostable bags, and flexible packaging, offering superior biodegradability in soil and industrial composting environments. Both materials support circular economy goals, with Ingeo favoring consumer products requiring transparency and durability, while Mater-Bi emphasizes compostable, soil-friendly applications.

Environmental Impact and Sustainability

Ingeo bioplastic, derived from renewable plant starch such as corn, offers a lower carbon footprint and greater biodegradability compared to traditional plastics, contributing to reduced greenhouse gas emissions in its life cycle. Mater-Bi, made from biodegradable starches and biodegradable polymers, excels in compostability and soil health benefits, breaking down completely in industrial composting conditions without leaving harmful residues. Both Ingeo and Mater-Bi promote circular economy principles, but Ingeo's renewable origin and carbon neutrality potential position it as a more sustainable alternative in large-scale applications.

Certification and Regulatory Compliance

Ingeo bioplastic by NatureWorks holds certifications such as FDA approval for food contact and is certified compostable under ASTM D6400 and EN 13432 standards, ensuring compliance with global food safety and compostability regulations. Mater-Bi, produced by Novamont, meets the European EN 13432 certification and is also certified according to the OK compost INDUSTRIAL standard, reflecting compliance with European Union directives on biodegradable and compostable materials. Both bioplastics adhere to strict regulatory frameworks, but Ingeo is often favored in applications requiring USDA BioPreferred certification and broader international food safety approvals.

Cost and Market Availability

Ingeo bioplastic, derived from fermented plant sugars primarily corn, generally has a higher production cost compared to Mater-Bi, which is based on starches and biodegradable polyesters. Mater-Bi benefits from a broader market availability, especially in Europe, due to its established presence and compatibility with existing composting infrastructures. Cost efficiency and widespread distribution make Mater-Bi a competitive option for large-scale applications, while Ingeo targets high-performance markets requiring specific mechanical properties.

Future Developments and Innovations

Ingeo bioplastic, derived from renewable plant sugars, advances through ongoing research targeting enhanced biodegradability and mechanical strength for broader industrial applications. Mater-Bi, a starch-based bioplastic, focuses innovation on improving compostability and compatibility with existing waste management systems to meet circular economy goals. Future developments in both materials emphasize scaling sustainable production processes and integrating nanotechnology to boost performance and ecological impact.

Ingeo vs Mater-Bi Infographic

materialdif.com

materialdif.com