Corn-based PLA and sugarcane-based PLA are both biodegradable bioplastics derived from renewable resources, offering eco-friendly alternatives to traditional plastics. Sugarcane-based PLA typically has a lower carbon footprint due to more efficient photosynthesis and higher biomass yield compared to corn-based PLA. Both types provide comparable mechanical properties, but sourcing and sustainability profiles vary, influencing their suitability for different applications.

Table of Comparison

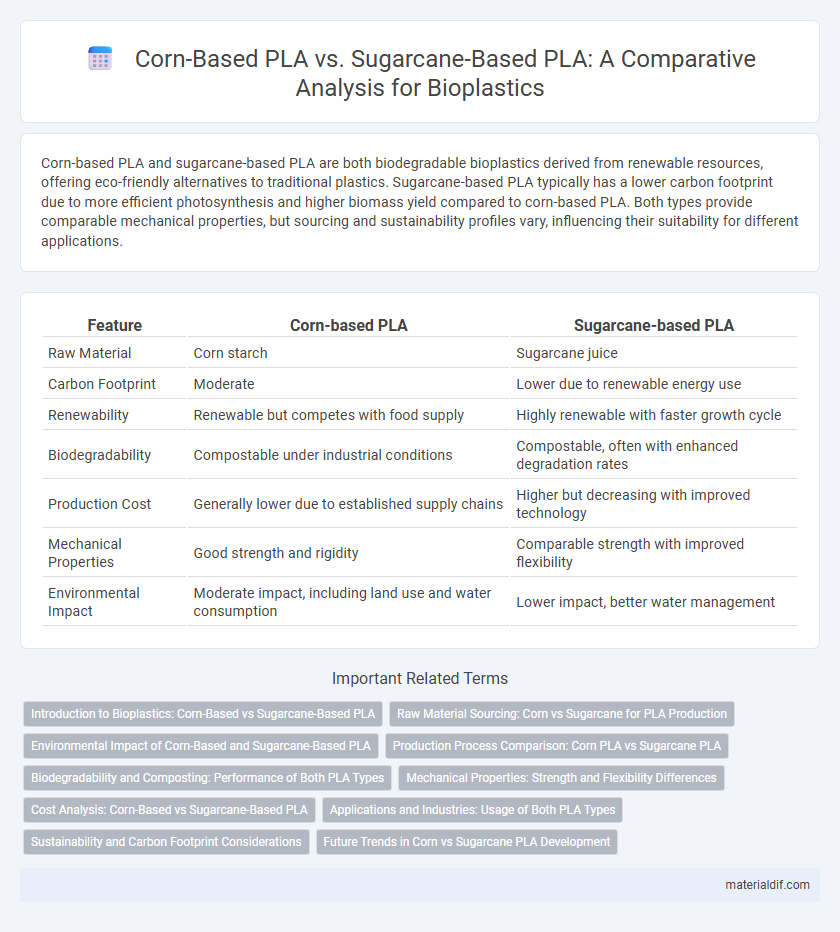

| Feature | Corn-based PLA | Sugarcane-based PLA |

|---|---|---|

| Raw Material | Corn starch | Sugarcane juice |

| Carbon Footprint | Moderate | Lower due to renewable energy use |

| Renewability | Renewable but competes with food supply | Highly renewable with faster growth cycle |

| Biodegradability | Compostable under industrial conditions | Compostable, often with enhanced degradation rates |

| Production Cost | Generally lower due to established supply chains | Higher but decreasing with improved technology |

| Mechanical Properties | Good strength and rigidity | Comparable strength with improved flexibility |

| Environmental Impact | Moderate impact, including land use and water consumption | Lower impact, better water management |

Introduction to Bioplastics: Corn-Based vs Sugarcane-Based PLA

Corn-based PLA and sugarcane-based PLA are two prominent types of bioplastics derived from renewable resources, with corn-based PLA primarily utilizing starch extracted from corn kernels and sugarcane-based PLA being produced from sucrose in sugarcane juice. Both types of polylactic acid (PLA) offer biodegradable alternatives to petroleum-based plastics, but sugarcane-based PLA often demonstrates a lower carbon footprint due to the efficient photosynthesis and higher biomass yield of sugarcane plants. Key considerations in selecting between these bioplastics include regional agricultural practices, lifecycle greenhouse gas emissions, and the impact on food crop resources.

Raw Material Sourcing: Corn vs Sugarcane for PLA Production

Corn-based PLA relies heavily on corn starch, predominantly sourced from the United States and China, offering a consistent and widely available raw material supply. Sugarcane-based PLA uses sugarcane juice extracted mainly in Brazil and India, providing a renewable and rapidly growing biomass source with lower input requirements. The sugarcane route generally results in higher biomass yield per hectare and better land use efficiency compared to corn cultivation for PLA production.

Environmental Impact of Corn-Based and Sugarcane-Based PLA

Corn-based PLA generates higher greenhouse gas emissions and requires more water compared to sugarcane-based PLA due to intensive agricultural inputs and land use practices. Sugarcane-based PLA benefits from the crop's high yield and efficient photosynthesis, resulting in lower carbon footprint and reduced resource consumption. Life cycle assessments reveal sugarcane PLA as a more sustainable option with significant reductions in energy use, water footprint, and overall environmental impact.

Production Process Comparison: Corn PLA vs Sugarcane PLA

Corn-based PLA production involves fermenting corn starch to produce lactic acid, which is then polymerized into polylactic acid, utilizing a well-established supply chain predominantly in North America. Sugarcane-based PLA derives from fermenting sugar extracted from sugarcane juice, benefiting from higher biomass yields per hectare and lower greenhouse gas emissions, especially prevalent in tropical regions like Brazil. The sugarcane PLA production process is typically more energy-efficient and sustainable, leveraging renewable energy sources and byproduct valorization compared to corn PLA's heavier reliance on synthetic fertilizers and intensive irrigation.

Biodegradability and Composting: Performance of Both PLA Types

Corn-based PLA and sugarcane-based PLA demonstrate similar biodegradability profiles, breaking down effectively under industrial composting conditions within 90 to 180 days. Both types require controlled temperature and humidity environments to achieve optimal composting performance, with sugarcane-based PLA sometimes exhibiting slightly faster degradation due to its molecular structure. In home composting settings, both PLA variants degrade much more slowly, often persisting beyond typical compost cycle durations.

Mechanical Properties: Strength and Flexibility Differences

Corn-based PLA typically exhibits higher tensile strength but lower flexibility compared to sugarcane-based PLA, making it more suitable for rigid packaging applications. Sugarcane-based PLA offers enhanced elongation at break and better impact resistance, providing greater flexibility for manufacturing films and flexible containers. The choice between these bioplastics depends on the mechanical requirements of the end-use product, balancing strength and ductility.

Cost Analysis: Corn-Based vs Sugarcane-Based PLA

Corn-based PLA generally exhibits lower production costs due to established supply chains and higher corn yields per hectare, making it more economically viable for large-scale manufacturing. Sugarcane-based PLA demands higher initial investment because of seasonal harvesting and geographic limitations, but its increased sugar content can enhance fermentation efficiency, potentially reducing processing expenses. Market volatility in feedstock prices and regional infrastructure significantly influence the overall cost competitiveness between corn-based and sugarcane-based PLA production.

Applications and Industries: Usage of Both PLA Types

Corn-based PLA is extensively used in packaging, disposable cutlery, and medical implants due to its high biocompatibility and ease of processing. Sugarcane-based PLA finds significant applications in the textile industry, automotive components, and 3D printing because of its strong mechanical properties and renewable sourcing. Both types contribute to sustainable product manufacturing across consumer goods, agriculture, and electronics sectors.

Sustainability and Carbon Footprint Considerations

Corn-based PLA typically has a higher carbon footprint due to intensive agricultural practices, including significant fertilizer and pesticide use, which can lead to soil degradation and water pollution. Sugarcane-based PLA offers enhanced sustainability through efficient photosynthesis and higher biomass yield, resulting in lower greenhouse gas emissions and improved carbon sequestration during cultivation. Lifecycle assessments reveal sugarcane PLA's advantage in reducing overall environmental impact, making it a more sustainable choice for biodegradable plastic production.

Future Trends in Corn vs Sugarcane PLA Development

Future trends in corn-based PLA focus on enhancing carbon capture efficiency and reducing land use through genetically modified crops, while sugarcane-based PLA development emphasizes improving yield per hectare and integrating biorefinery processes to utilize bagasse and molasses effectively. Advances in metabolic engineering for both feedstocks aim to lower production costs and improve polymer properties such as biodegradability and thermal resistance. Market forecasts predict a growing preference for sugarcane PLA in regions with favorable climates due to sustainable agricultural practices and lower greenhouse gas emissions during cultivation.

Corn-based PLA vs Sugarcane-based PLA Infographic

materialdif.com

materialdif.com