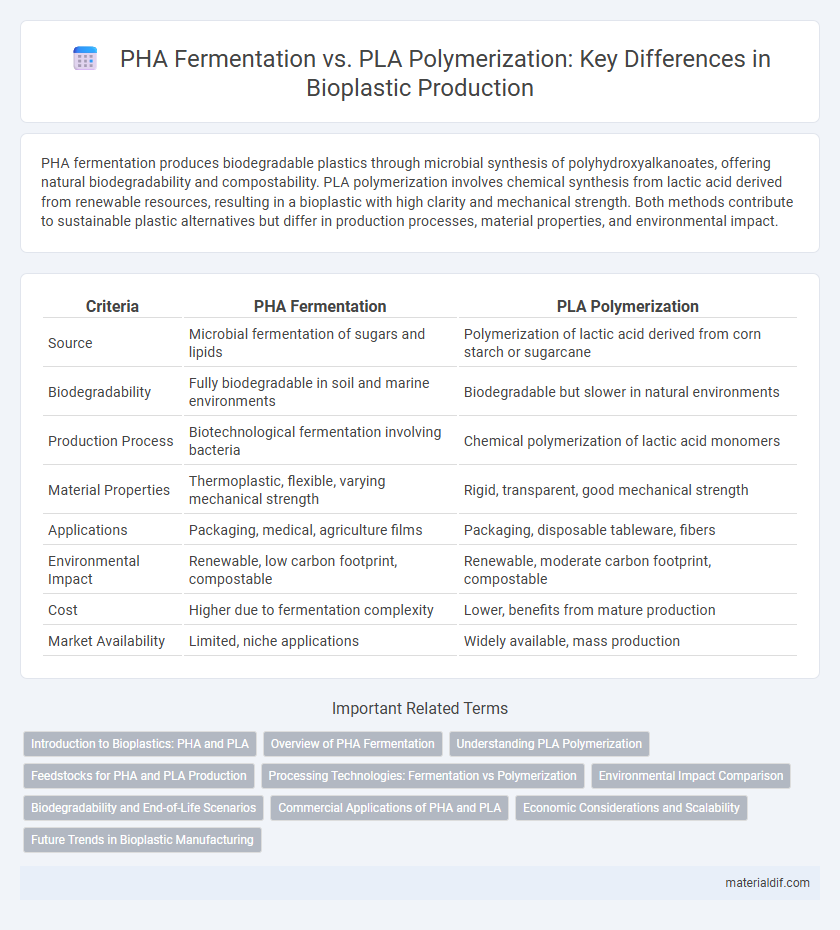

PHA fermentation produces biodegradable plastics through microbial synthesis of polyhydroxyalkanoates, offering natural biodegradability and compostability. PLA polymerization involves chemical synthesis from lactic acid derived from renewable resources, resulting in a bioplastic with high clarity and mechanical strength. Both methods contribute to sustainable plastic alternatives but differ in production processes, material properties, and environmental impact.

Table of Comparison

| Criteria | PHA Fermentation | PLA Polymerization |

|---|---|---|

| Source | Microbial fermentation of sugars and lipids | Polymerization of lactic acid derived from corn starch or sugarcane |

| Biodegradability | Fully biodegradable in soil and marine environments | Biodegradable but slower in natural environments |

| Production Process | Biotechnological fermentation involving bacteria | Chemical polymerization of lactic acid monomers |

| Material Properties | Thermoplastic, flexible, varying mechanical strength | Rigid, transparent, good mechanical strength |

| Applications | Packaging, medical, agriculture films | Packaging, disposable tableware, fibers |

| Environmental Impact | Renewable, low carbon footprint, compostable | Renewable, moderate carbon footprint, compostable |

| Cost | Higher due to fermentation complexity | Lower, benefits from mature production |

| Market Availability | Limited, niche applications | Widely available, mass production |

Introduction to Bioplastics: PHA and PLA

Polyhydroxyalkanoates (PHA) are bioplastics produced through microbial fermentation of renewable carbon sources, offering biodegradability and biocompatibility tailored for medical and packaging applications. Polylactic acid (PLA) is synthesized via chemical polymerization of lactic acid derived from fermented biomass and is widely used for its rigidity and transparency in consumer goods. Both PHA and PLA represent sustainable alternatives to petrochemical plastics, differing primarily in production methods and material properties.

Overview of PHA Fermentation

PHA fermentation involves the microbial synthesis of polyhydroxyalkanoates using renewable carbon sources such as sugars, lipids, or waste materials, producing bioplastics with biodegradability and biocompatibility. This biological process typically requires specific bacteria like Cupriavidus necator under nutrient-limited conditions, leading to intracellular accumulation of PHAs as energy storage. Compared to PLA polymerization, PHA fermentation offers a fully biosynthetic route without the need for petrochemical derivatives, enabling sustainable production of versatile biopolyesters.

Understanding PLA Polymerization

PLA polymerization involves the ring-opening polymerization of lactide, a cyclic dimer derived from lactic acid, producing polylactic acid (PLA) with high molecular weight and controlled stereochemistry. This process allows precise manipulation of polymer properties, such as crystallinity and mechanical strength, critical for diverse bioplastic applications. Understanding PLA polymerization is essential for optimizing reaction conditions, catalysts, and molecular architecture to enhance biodegradability and performance in sustainable packaging solutions.

Feedstocks for PHA and PLA Production

PHA production primarily relies on organic feedstocks such as vegetable oils, sugars, and agricultural waste, which are metabolized by microorganisms during fermentation. PLA synthesis uses lactic acid derived mainly from the fermentation of renewable carbohydrate sources like corn starch or sugarcane through polymerization. The choice of feedstock significantly impacts the sustainability and cost-efficiency of both PHA and PLA bioplastics.

Processing Technologies: Fermentation vs Polymerization

PHA fermentation utilizes microbial fermentation of renewable substrates to produce biodegradable polyhydroxyalkanoates, enabling direct synthesis of biopolymers with diverse monomer compositions. PLA polymerization involves chemical processes such as ring-opening polymerization of lactic acid derived from biomass, resulting in a highly crystalline and thermoplastic polymer with controlled molecular weight. Fermentation offers versatility in monomer production with potential for waste valorization, while polymerization provides precise control over polymer structure and properties for industrial-scale manufacturing.

Environmental Impact Comparison

PHA fermentation produces bioplastics through microbial synthesis using renewable feedstocks, resulting in complete biodegradability in soil and marine environments with minimal toxic residues. PLA polymerization, derived from lactic acid fermentation followed by chemical polymerization, offers compostability primarily under industrial conditions but may persist in natural settings and generate microplastics. The environmental impact favors PHA for its superior biodegradability and lower ecological footprint, while PLA's production process consumes less energy but poses challenges in end-of-life degradation.

Biodegradability and End-of-Life Scenarios

PHA fermentation produces polyhydroxyalkanoates that are fully biodegradable in various environments, including marine and soil conditions, offering superior end-of-life compostability compared to PLA. PLA polymerization yields polylactic acid with limited biodegradability, primarily requiring industrial composting facilities to break down effectively, which can restrict its environmental disposal options. The choice between PHA and PLA significantly impacts sustainability strategies, with PHA providing broader biodegradability and more flexible, environmentally friendly end-of-life scenarios.

Commercial Applications of PHA and PLA

PHA fermentation offers biodegradable bioplastics commonly used in medical implants, packaging films, and agricultural mulch due to their biocompatibility and compostability. PLA polymerization dominates the market for food packaging, disposable tableware, and 3D printing materials because of its cost-effectiveness and ease of processing. Commercial applications prioritize PHA for specialty uses requiring biodegradability in marine environments, while PLA serves large-scale commodity markets leveraging renewable resources like corn starch.

Economic Considerations and Scalability

PHA fermentation involves microbial synthesis of polyhydroxyalkanoates from renewable substrates, enabling cost-effective production through waste valorization but requiring careful optimization of fermentation conditions to enhance yield and reduce operational expenses. PLA polymerization relies on the polymerization of lactic acid, often sourced from starch or sugar crops, leading to lower processing times and established industrial scaling but facing feedstock cost volatility and competition with food resources. Economic considerations for PHA favor sustainable waste-based inputs and potential for diverse monomer compositions, while PLA benefits from mature supply chains and scalability, although raw material costs and energy consumption remain critical factors in production economics.

Future Trends in Bioplastic Manufacturing

PHA fermentation utilizes microbial processes to convert organic substrates into biodegradable polyhydroxyalkanoates, offering fully bio-based and compostable alternatives with enhanced environmental benefits. PLA polymerization involves the ring-opening polymerization of lactic acid derived from renewable resources, producing bioplastics with high clarity and processability but limited biodegradability under natural conditions. Future trends emphasize integrating hybrid production methods that combine fermentation and polymerization to optimize material properties, scalability, and sustainability in bioplastic manufacturing.

PHA fermentation vs PLA polymerization Infographic

materialdif.com

materialdif.com