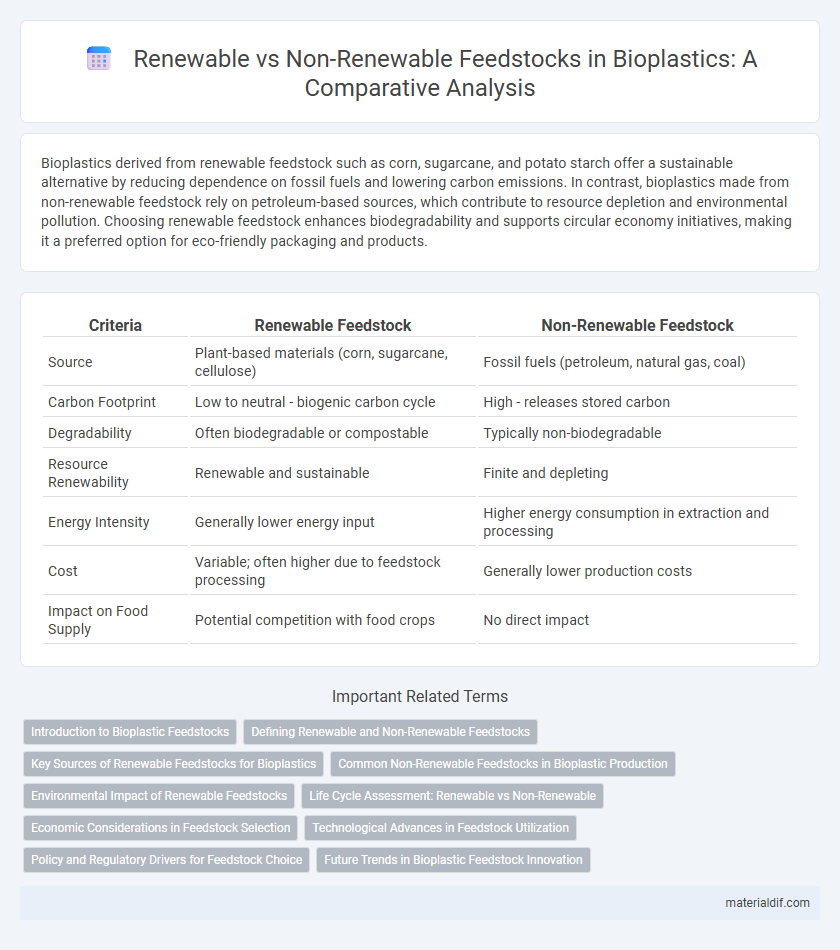

Bioplastics derived from renewable feedstock such as corn, sugarcane, and potato starch offer a sustainable alternative by reducing dependence on fossil fuels and lowering carbon emissions. In contrast, bioplastics made from non-renewable feedstock rely on petroleum-based sources, which contribute to resource depletion and environmental pollution. Choosing renewable feedstock enhances biodegradability and supports circular economy initiatives, making it a preferred option for eco-friendly packaging and products.

Table of Comparison

| Criteria | Renewable Feedstock | Non-Renewable Feedstock |

|---|---|---|

| Source | Plant-based materials (corn, sugarcane, cellulose) | Fossil fuels (petroleum, natural gas, coal) |

| Carbon Footprint | Low to neutral - biogenic carbon cycle | High - releases stored carbon |

| Degradability | Often biodegradable or compostable | Typically non-biodegradable |

| Resource Renewability | Renewable and sustainable | Finite and depleting |

| Energy Intensity | Generally lower energy input | Higher energy consumption in extraction and processing |

| Cost | Variable; often higher due to feedstock processing | Generally lower production costs |

| Impact on Food Supply | Potential competition with food crops | No direct impact |

Introduction to Bioplastic Feedstocks

Bioplastic feedstocks are derived from renewable sources such as corn starch, sugarcane, and cellulose, distinguishing them from non-renewable feedstocks like petroleum-based materials. Renewable feedstocks offer a sustainable alternative by reducing carbon footprint and reliance on fossil fuels, enhancing environmental benefits. Understanding the differences between these feedstock types is crucial for advancing bioplastic development and promoting eco-friendly production.

Defining Renewable and Non-Renewable Feedstocks

Renewable feedstocks for bioplastic production originate from biomass sources such as corn, sugarcane, and cellulose, which can be replenished naturally through agricultural cycles. Non-renewable feedstocks derive mainly from petrochemical resources like crude oil and natural gas, which are finite and contribute to environmental degradation. Defining renewable feedstocks emphasizes their sustainable capacity for carbon capture and recyclability, while non-renewable feedstocks highlight dependency on fossil fuels and associated greenhouse gas emissions.

Key Sources of Renewable Feedstocks for Bioplastics

Key sources of renewable feedstocks for bioplastics include starches derived from corn, potatoes, and wheat, as well as cellulose from wood, grasses, and agricultural residues. Vegetable oils such as soybean, palm, and castor seed oils provide lipid-based feedstocks that contribute to bioplastic production. Algae and microbial biomass also serve as emerging renewable sources rich in polysaccharides and lipids, supporting sustainable bioplastic synthesis.

Common Non-Renewable Feedstocks in Bioplastic Production

Common non-renewable feedstocks in bioplastic production primarily include fossil-based resources such as crude oil, natural gas, and coal, which serve as the raw materials for producing conventional bioplastics like bio-based polyethylene and bio-based polypropylene. These feedstocks contribute to the carbon footprint and environmental concerns associated with non-renewable resource depletion and greenhouse gas emissions. Switching to renewable feedstocks like starch, cellulose, and vegetable oils can enhance sustainability by reducing reliance on finite fossil resources while promoting biodegradability and lower life-cycle impacts.

Environmental Impact of Renewable Feedstocks

Renewable feedstocks in bioplastic production significantly reduce carbon footprint by utilizing materials like corn, sugarcane, and cellulose that absorb CO2 during growth, promoting a closed carbon cycle. These feedstocks often lead to lower greenhouse gas emissions and decreased reliance on fossil fuels compared to non-renewable alternatives such as petroleum-based feedstocks. Their biodegradability and potential for soil regeneration further enhance environmental sustainability, reducing pollution and conserving ecosystem health.

Life Cycle Assessment: Renewable vs Non-Renewable

Life Cycle Assessment (LCA) reveals that bioplastics derived from renewable feedstocks, such as corn or sugarcane, typically have lower carbon footprints compared to those made from non-renewable fossil fuels like petroleum. Renewable feedstocks contribute to reduced greenhouse gas emissions and enhanced biodegradability, improving overall environmental sustainability. However, LCA also highlights potential impacts of agricultural practices on land use, water consumption, and biodiversity that must be managed for optimal ecological benefits.

Economic Considerations in Feedstock Selection

Renewable feedstocks for bioplastics, such as corn starch and sugarcane, tend to have higher upfront costs but offer long-term economic benefits through sustainability incentives and reduced dependency on fluctuating fossil fuel markets. Non-renewable feedstocks, primarily petroleum-based, generally provide lower initial costs and well-established supply chains but face increasing volatility in pricing and regulatory penalties tied to carbon emissions. The economic trade-off between renewable and non-renewable feedstocks hinges on factors like feedstock availability, processing costs, environmental compliance expenses, and market demand for eco-friendly products.

Technological Advances in Feedstock Utilization

Technological advances in bioplastic production have enhanced the utilization of renewable feedstocks such as corn starch, sugarcane, and cellulose, enabling higher yield and lower energy consumption compared to traditional petroleum-based feedstocks. Innovations in enzymatic hydrolysis and microbial fermentation optimize the conversion of biomass into biopolymers, reducing reliance on fossil fuels and decreasing carbon footprints. Emerging processes like bioelectrochemical synthesis and genetic engineering of feedstock crops further improve efficiency and sustainability in bioplastic manufacturing.

Policy and Regulatory Drivers for Feedstock Choice

Policy and regulatory frameworks increasingly favor renewable feedstocks due to mandates for carbon reduction and sustainable sourcing in bioplastic production. Governments implement incentives, such as tax credits and subsidies, to promote bio-based materials sourced from agricultural residues and other renewable resources while imposing restrictions or penalties on non-renewable fossil-based feedstocks. These policies accelerate the shift towards renewable feedstocks by aligning industry practices with environmental targets and international climate agreements.

Future Trends in Bioplastic Feedstock Innovation

Future trends in bioplastic feedstock innovation emphasize a shift from traditional non-renewable feedstocks such as petroleum-based raw materials toward renewable sources like agricultural residues, algae, and cellulose. Advances in biotechnology and synthetic biology are enabling the development of high-yield, sustainable feedstocks that reduce environmental impact and enhance biodegradability. The integration of waste biomass and carbon capture technologies further accelerates the transition to circular economy models in bioplastic production.

Renewable feedstock vs Non-renewable feedstock Infographic

materialdif.com

materialdif.com