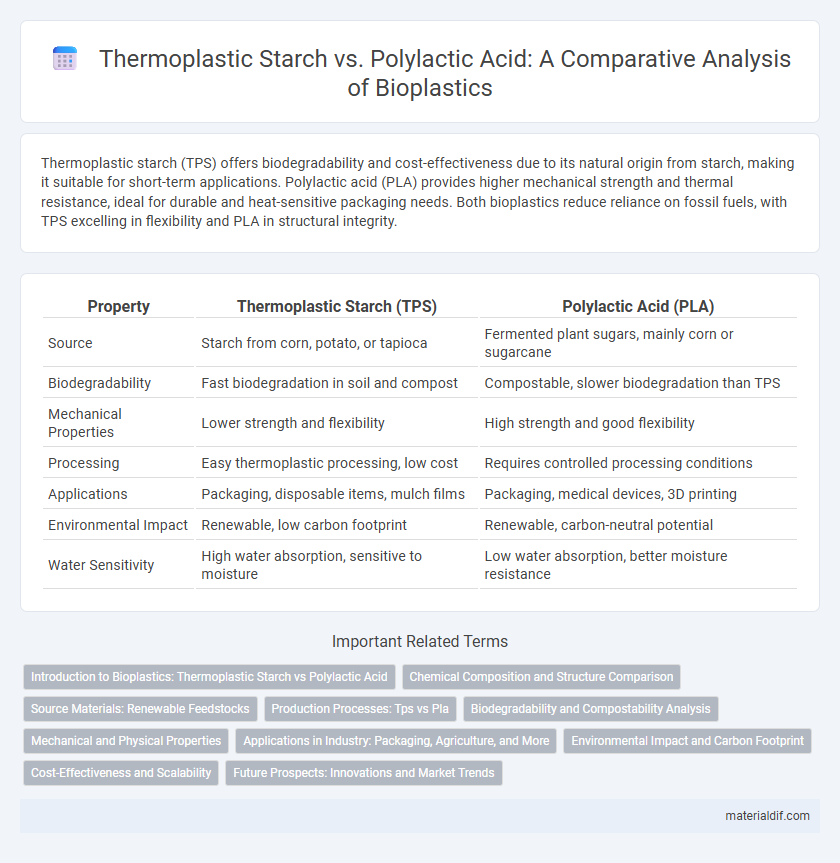

Thermoplastic starch (TPS) offers biodegradability and cost-effectiveness due to its natural origin from starch, making it suitable for short-term applications. Polylactic acid (PLA) provides higher mechanical strength and thermal resistance, ideal for durable and heat-sensitive packaging needs. Both bioplastics reduce reliance on fossil fuels, with TPS excelling in flexibility and PLA in structural integrity.

Table of Comparison

| Property | Thermoplastic Starch (TPS) | Polylactic Acid (PLA) |

|---|---|---|

| Source | Starch from corn, potato, or tapioca | Fermented plant sugars, mainly corn or sugarcane |

| Biodegradability | Fast biodegradation in soil and compost | Compostable, slower biodegradation than TPS |

| Mechanical Properties | Lower strength and flexibility | High strength and good flexibility |

| Processing | Easy thermoplastic processing, low cost | Requires controlled processing conditions |

| Applications | Packaging, disposable items, mulch films | Packaging, medical devices, 3D printing |

| Environmental Impact | Renewable, low carbon footprint | Renewable, carbon-neutral potential |

| Water Sensitivity | High water absorption, sensitive to moisture | Low water absorption, better moisture resistance |

Introduction to Bioplastics: Thermoplastic Starch vs Polylactic Acid

Thermoplastic starch (TPS) and polylactic acid (PLA) are two prominent bioplastics derived from renewable resources, offering sustainable alternatives to conventional plastics. TPS is produced by plasticizing natural starch, making it biodegradable and cost-effective, while PLA is synthesized from fermented plant sugars, providing high strength and compostability. These bioplastics serve diverse applications in packaging, agriculture, and disposable products, with TPS favored for flexibility and PLA for rigidity and clarity.

Chemical Composition and Structure Comparison

Thermoplastic starch (TPS) consists primarily of gelatinized starch molecules, mainly amylose and amylopectin, chemically modified through plasticization to achieve thermoplasticity, resulting in a semi-crystalline structure with strong hydrogen bonding. Polylactic acid (PLA) is a biodegradable aliphatic polyester synthesized from lactic acid monomers via ring-opening polymerization, exhibiting a highly crystalline or amorphous structure depending on stereochemical composition. TPS features a polysaccharide-based backbone with hydroxyl groups, promoting hydrophilicity, whereas PLA's ester linkages in its polyester chain impart hydrophobicity and greater mechanical strength.

Source Materials: Renewable Feedstocks

Thermoplastic starch is derived from abundant renewable feedstocks such as corn, potato, and cassava starches, making it highly sustainable and cost-effective. Polylactic acid (PLA) is produced from fermented plant sugars, primarily sourced from corn and sugarcane, offering a biodegradable alternative with excellent mechanical properties. Both bioplastics rely on renewable agricultural resources, reducing dependence on fossil fuels and contributing to carbon neutrality.

Production Processes: Tps vs Pla

Thermoplastic starch (TPS) is produced by plasticizing starch with water, glycerol, or other plasticizers under heat and shear, resulting in a biodegradable material that is cost-effective and derived from abundant natural sources. Polylactic acid (PLA) is synthesized through the fermentation of renewable biomass, such as corn or sugarcane, followed by polymerization processes that yield a more durable and higher-performance bioplastic. TPS production involves simpler, energy-efficient methods but often results in lower mechanical strength, whereas PLA manufacturing requires more complex fermentation and polymerization technologies, producing bioplastics better suited for packaging and medical applications.

Biodegradability and Compostability Analysis

Thermoplastic starch (TPS) exhibits high biodegradability due to its natural polysaccharide structure, breaking down rapidly in both aerobic and anaerobic composting conditions within weeks. Polylactic acid (PLA), derived from renewable resources like corn starch or sugarcane, shows slower biodegradation and requires industrial composting environments with elevated temperatures above 58degC to achieve complete compostability. Comparative analysis indicates TPS is more suitable for home composting applications, while PLA demands controlled industrial composting facilities to ensure effective degradation.

Mechanical and Physical Properties

Thermoplastic starch (TPS) exhibits lower tensile strength and rigidity compared to polylactic acid (PLA), making it more flexible but less durable under mechanical stress. PLA offers superior mechanical properties including higher tensile strength, modulus, and thermal resistance, contributing to its widespread use in packaging and biomedical applications. TPS is highly biodegradable and absorbs moisture readily, whereas PLA has better barrier properties and lower water absorption, enhancing its physical stability.

Applications in Industry: Packaging, Agriculture, and More

Thermoplastic starch (TPS) is widely used in packaging and agriculture due to its biodegradability, affordability, and ease of processing, making it ideal for disposable items like bags and mulch films. Polylactic acid (PLA) offers higher mechanical strength and clarity, suitable for rigid packaging, food containers, and medical implants, with growing interest in 3D printing applications. Both bioplastics contribute to reducing carbon footprints, but TPS is favored in short-term use, while PLA supports products requiring durability and extended shelf life.

Environmental Impact and Carbon Footprint

Thermoplastic starch (TPS) and polylactic acid (PLA) are both biodegradable bioplastics with distinct environmental impacts and carbon footprints. TPS, derived from renewable starch sources like corn or potato, generally has a lower carbon footprint due to its simpler production process and lower energy requirements. PLA, synthesized from fermented plant sugars, offers higher durability and compostability but involves more intensive industrial processing, resulting in a moderately higher carbon footprint compared to TPS.

Cost-Effectiveness and Scalability

Thermoplastic starch (TPS) offers superior cost-effectiveness due to its abundant raw material sources like corn and potato starch, making it cheaper to produce compared to polylactic acid (PLA). TPS exhibits high scalability as it leverages well-established starch processing infrastructure, facilitating mass production without significant investment in new technologies. In contrast, PLA production involves fermentation and polymerization processes that increase manufacturing costs and require specialized bioreactors, limiting rapid scalability despite its favorable mechanical properties.

Future Prospects: Innovations and Market Trends

Thermoplastic starch (TPS) and polylactic acid (PLA) are advancing rapidly in biodegradable plastic markets due to innovations in enhanced compatibility and mechanical properties. Emerging research on TPS blends aims to overcome moisture sensitivity, boosting its application scope in packaging and agriculture. The PLA market is expected to grow significantly, driven by improvements in production efficiency, renewable feedstocks, and rising demand for sustainable bioplastics in the automotive and consumer goods sectors.

Thermoplastic starch vs Polylactic acid Infographic

materialdif.com

materialdif.com