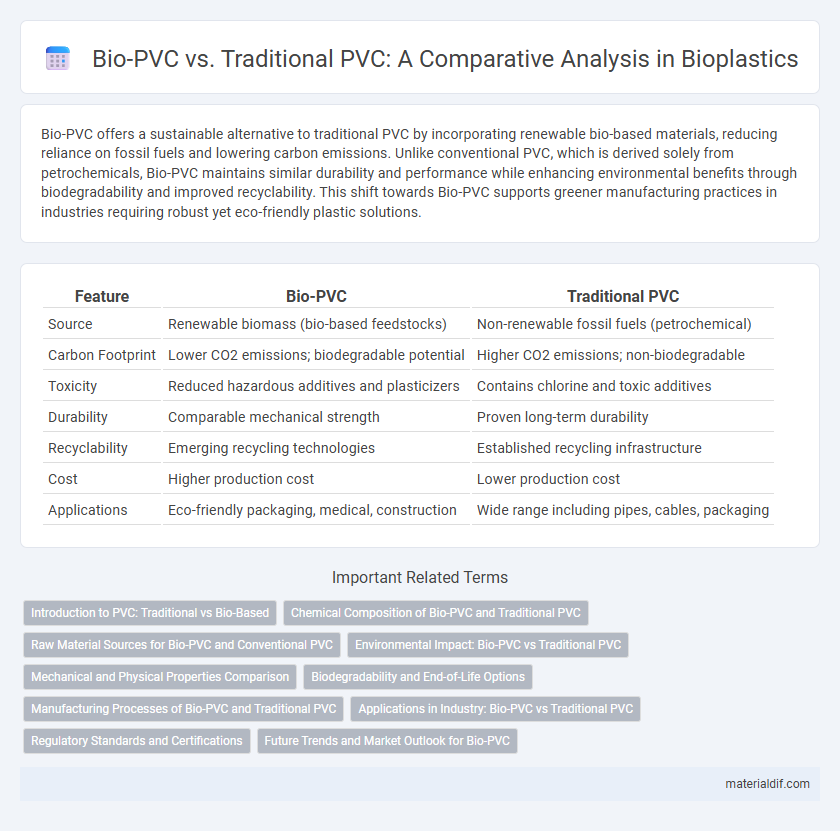

Bio-PVC offers a sustainable alternative to traditional PVC by incorporating renewable bio-based materials, reducing reliance on fossil fuels and lowering carbon emissions. Unlike conventional PVC, which is derived solely from petrochemicals, Bio-PVC maintains similar durability and performance while enhancing environmental benefits through biodegradability and improved recyclability. This shift towards Bio-PVC supports greener manufacturing practices in industries requiring robust yet eco-friendly plastic solutions.

Table of Comparison

| Feature | Bio-PVC | Traditional PVC |

|---|---|---|

| Source | Renewable biomass (bio-based feedstocks) | Non-renewable fossil fuels (petrochemical) |

| Carbon Footprint | Lower CO2 emissions; biodegradable potential | Higher CO2 emissions; non-biodegradable |

| Toxicity | Reduced hazardous additives and plasticizers | Contains chlorine and toxic additives |

| Durability | Comparable mechanical strength | Proven long-term durability |

| Recyclability | Emerging recycling technologies | Established recycling infrastructure |

| Cost | Higher production cost | Lower production cost |

| Applications | Eco-friendly packaging, medical, construction | Wide range including pipes, cables, packaging |

Introduction to PVC: Traditional vs Bio-Based

PVC, or polyvinyl chloride, is a widely used plastic in construction and packaging, traditionally synthesized from petrochemical sources. Bio-PVC is derived from renewable biomass materials such as sugarcane, reducing dependence on fossil fuels and lowering carbon emissions. Both types maintain similar physical properties, but bio-based PVC offers enhanced sustainability by integrating plant-based feedstocks into conventional production processes.

Chemical Composition of Bio-PVC and Traditional PVC

Bio-PVC is derived from renewable plant-based materials such as sugarcane or corn starch, incorporating bio-based ethylene units that reduce fossil fuel dependency. Traditional PVC is synthesized from petrochemical feedstocks, primarily vinyl chloride monomer, which is obtained through the chlorination of ethylene derived from crude oil or natural gas. Both bio-PVC and traditional PVC share similar polymer backbones composed of repeating vinyl chloride units, but bio-PVC distinguishes itself by utilizing bio-ethylene as a sustainable feedstock, resulting in a comparable chemical structure with a lower carbon footprint.

Raw Material Sources for Bio-PVC and Conventional PVC

Bio-PVC is derived from renewable biological sources such as sugarcane, corn, and other plant-based feedstocks, reducing reliance on fossil fuels and lowering carbon footprint. Traditional PVC is synthesized primarily from petrochemical raw materials, including ethylene derived from crude oil and chlorine obtained from salt through energy-intensive processes. The shift to bio-based raw materials in Bio-PVC production supports sustainability goals by utilizing biodegradable resources and minimizing environmental impact associated with fossil fuel extraction and processing.

Environmental Impact: Bio-PVC vs Traditional PVC

Bio-PVC significantly reduces environmental impact by using renewable plant-based materials, lowering carbon emissions compared to traditional PVC derived from fossil fuels. Unlike traditional PVC, Bio-PVC production minimizes toxic chemical release and enhances biodegradability, decreasing long-term pollution. The lifecycle of Bio-PVC results in less energy consumption and reduced greenhouse gas emissions, promoting a more sustainable alternative in polymer manufacturing.

Mechanical and Physical Properties Comparison

Bio-PVC exhibits mechanical properties similar to traditional PVC, including high tensile strength and impact resistance, making it suitable for a wide range of industrial applications. Its physical properties offer comparable durability, flexibility, and thermal stability while providing the added benefit of reduced environmental impact due to its renewable bio-based content. Both materials maintain excellent chemical resistance, but Bio-PVC's biodegradability potential presents an advantage in sustainable manufacturing practices.

Biodegradability and End-of-Life Options

Bio-PVC offers enhanced biodegradability compared to traditional PVC, as it is derived from renewable resources that enable faster decomposition under industrial composting conditions. Traditional PVC is persistent in the environment, posing challenges due to its resistance to natural degradation and limited recycling options. End-of-life management for Bio-PVC includes industrial composting and potential chemical recycling, whereas traditional PVC typically relies on mechanical recycling or landfill disposal, contributing to long-term environmental persistence.

Manufacturing Processes of Bio-PVC and Traditional PVC

Bio-PVC is manufactured using bio-based ethylene derived from renewable resources such as sugarcane or corn, which undergoes polymerization with chlorine to form polyvinyl chloride. Traditional PVC production relies on petroleum-based ethylene obtained through fossil fuel refining followed by chlorination and polymerization, involving energy-intensive processes with higher carbon emissions. The bio-PVC manufacturing process reduces reliance on non-renewable feedstocks and lowers greenhouse gas emissions compared to the conventional PVC production cycle.

Applications in Industry: Bio-PVC vs Traditional PVC

Bio-PVC offers similar durability and chemical resistance to traditional PVC, making it suitable for applications in construction, automotive parts, and electrical insulation while reducing environmental impact through renewable bio-based feedstocks. Industries favor Bio-PVC in packaging and piping where sustainability goals are prioritized, without compromising on performance standards. Traditional PVC remains dominant in large-scale infrastructure projects due to its established cost-effectiveness and material consistency.

Regulatory Standards and Certifications

Bio-PVC meets stringent regulatory standards such as REACH and RoHS, ensuring lower environmental impact and reduced toxic chemical content compared to traditional PVC. Certification programs like Cradle to Cradle and TUV OK Biobased validate the bio-based content and sustainability of Bio-PVC products. In contrast, traditional PVC often faces regulatory scrutiny due to the presence of hazardous additives like phthalates and chlorine, limiting its compliance with emerging environmental regulations.

Future Trends and Market Outlook for Bio-PVC

Bio-PVC is gaining momentum as a sustainable alternative to traditional PVC, leveraging renewable biomass while maintaining comparable physical properties and durability. Market projections indicate a compounded annual growth rate (CAGR) of over 10% through 2030, driven by increasing environmental regulations and consumer demand for eco-friendly materials. Advances in bio-based plasticizers and recycling technologies are expected to enhance Bio-PVC's cost-effectiveness and performance, securing its expanding role in construction, automotive, and packaging sectors.

Bio-PVC vs Traditional PVC Infographic

materialdif.com

materialdif.com