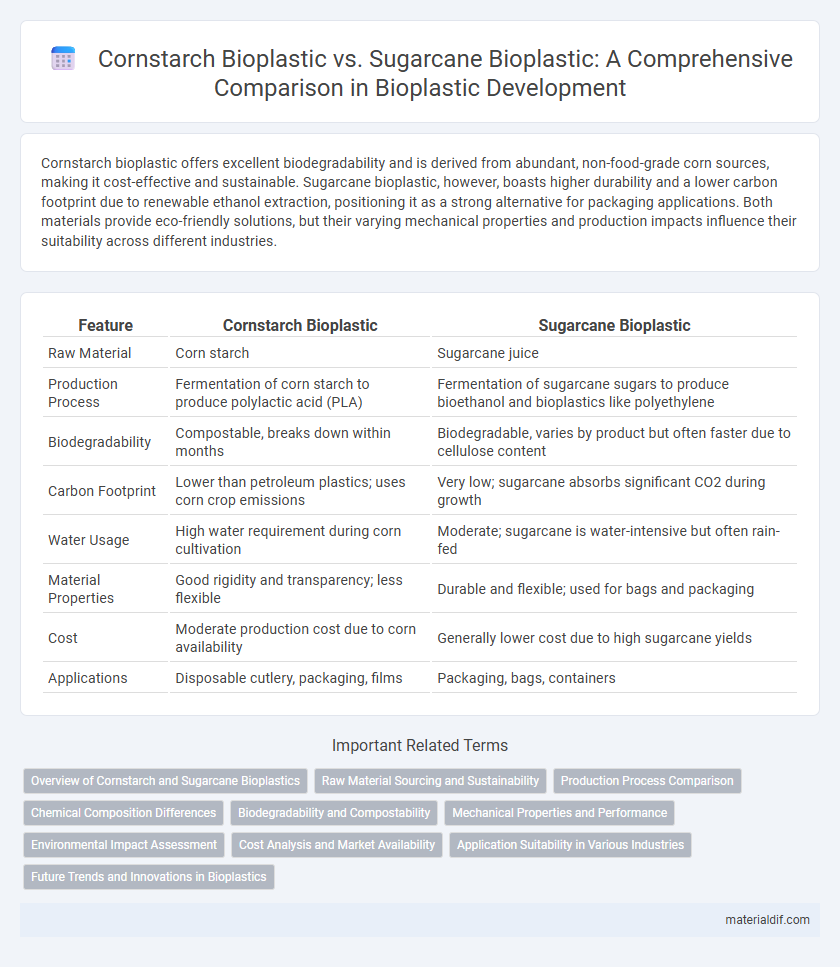

Cornstarch bioplastic offers excellent biodegradability and is derived from abundant, non-food-grade corn sources, making it cost-effective and sustainable. Sugarcane bioplastic, however, boasts higher durability and a lower carbon footprint due to renewable ethanol extraction, positioning it as a strong alternative for packaging applications. Both materials provide eco-friendly solutions, but their varying mechanical properties and production impacts influence their suitability across different industries.

Table of Comparison

| Feature | Cornstarch Bioplastic | Sugarcane Bioplastic |

|---|---|---|

| Raw Material | Corn starch | Sugarcane juice |

| Production Process | Fermentation of corn starch to produce polylactic acid (PLA) | Fermentation of sugarcane sugars to produce bioethanol and bioplastics like polyethylene |

| Biodegradability | Compostable, breaks down within months | Biodegradable, varies by product but often faster due to cellulose content |

| Carbon Footprint | Lower than petroleum plastics; uses corn crop emissions | Very low; sugarcane absorbs significant CO2 during growth |

| Water Usage | High water requirement during corn cultivation | Moderate; sugarcane is water-intensive but often rain-fed |

| Material Properties | Good rigidity and transparency; less flexible | Durable and flexible; used for bags and packaging |

| Cost | Moderate production cost due to corn availability | Generally lower cost due to high sugarcane yields |

| Applications | Disposable cutlery, packaging, films | Packaging, bags, containers |

Overview of Cornstarch and Sugarcane Bioplastics

Cornstarch bioplastic is derived from the polysaccharides present in corn kernels, offering biodegradability and compostability with applications in packaging and disposable items. Sugarcane bioplastic primarily involves bio-based polyethylene produced from sugarcane ethanol, noted for its renewable source and reduced carbon footprint compared to conventional plastics. Both materials contribute to sustainable alternatives but differ in raw material sources and end-use properties, influencing their environmental impact and industrial applications.

Raw Material Sourcing and Sustainability

Cornstarch bioplastic is derived from abundant, non-food-grade corn, promoting local agricultural waste utilization and reducing reliance on fossil fuels. Sugarcane bioplastic relies on renewable sugarcane crops, offering efficient carbon sequestration and lower greenhouse gas emissions during cultivation and processing. Both raw materials support biodegradability, yet sugarcane's high yield and regional adaptability provide enhanced sustainability for large-scale production.

Production Process Comparison

Cornstarch bioplastic production involves extracting glucose from corn kernels through enzymatic hydrolysis, followed by fermentation to produce lactic acid, which polymerizes into polylactic acid (PLA). Sugarcane bioplastic production primarily converts sucrose into fermentable sugars, then through similar fermentation processes, yields biopolymers like PLA or polyethylene variants from bioethanol. The sugarcane process generally requires less energy due to simpler extraction and higher crop yields, offering a potentially more sustainable production pathway.

Chemical Composition Differences

Cornstarch bioplastic primarily consists of amylose and amylopectin, which are polysaccharides derived from glucose units, making it biodegradable and flexible but prone to water sensitivity. Sugarcane bioplastic, mainly composed of sucrose and its fermentation products like polylactic acid (PLA), offers higher tensile strength and better moisture resistance due to its crystalline polymer structure. The chemical differences between cornstarch and sugarcane bioplastics influence their mechanical properties and environmental degradation rates, impacting their applications in packaging and disposable products.

Biodegradability and Compostability

Cornstarch bioplastic exhibits high biodegradability, breaking down efficiently in industrial composting facilities within 90 to 180 days due to its polysaccharide-rich composition. Sugarcane bioplastic, derived from bagasse, offers superior compostability with enhanced structural integrity, decomposing effectively in both industrial and home composting environments within 6 months. The choice between cornstarch and sugarcane bioplastics affects waste management strategies, emphasizing rapid biodegradation for cornstarch and versatile composting adaptability for sugarcane.

Mechanical Properties and Performance

Cornstarch bioplastics typically exhibit lower tensile strength and flexibility compared to sugarcane bioplastics, making them less suitable for applications requiring high durability. Sugarcane bioplastics demonstrate superior mechanical performance with enhanced impact resistance and elongation at break, which contributes to their growing preference in packaging. The higher crystallinity and polymer chain alignment in sugarcane-derived materials result in improved strength and stability under mechanical stress.

Environmental Impact Assessment

Cornstarch bioplastic generates lower greenhouse gas emissions during production compared to sugarcane bioplastic, but it requires more land and water resources, which can impact biodiversity and local ecosystems. Sugarcane bioplastic benefits from a higher yield per hectare and efficient use of sunlight, resulting in a more favorable carbon footprint and less pressure on agricultural land. Life cycle assessments highlight sugarcane bioplastic's better overall sustainability when factoring energy consumption and end-of-life biodegradability.

Cost Analysis and Market Availability

Cornstarch bioplastic generally offers lower production costs due to the abundant availability and lower price of corn in key markets like the United States. Sugarcane bioplastic tends to be more expensive because sugarcane cultivation and processing require higher energy inputs, particularly in regions such as Brazil where it dominates production. Market availability favors sugarcane bioplastic in tropical regions with established sugarcane industries, whereas cornstarch bioplastic is more prevalent in temperate zones with large corn supplies.

Application Suitability in Various Industries

Cornstarch bioplastic offers excellent biodegradability and is highly suitable for single-use packaging and agricultural films due to its compostability and ease of processing. Sugarcane bioplastic provides higher durability and heat resistance, making it ideal for automotive parts, electronics casings, and long-lasting consumer goods. Both materials support sustainability goals but cater to different industry requirements based on performance and environmental impact.

Future Trends and Innovations in Bioplastics

Cornstarch bioplastic and sugarcane bioplastic are driving future trends in sustainable packaging through enhanced biodegradability and reduced carbon footprints. Innovations in enzyme technology and fermentation processes are improving material strength and flexibility, making these bioplastics viable alternatives to conventional plastics. Emerging research on blending cornstarch and sugarcane fibers with nanomaterials promises to elevate performance metrics, optimize production costs, and expand applications across multiple industries.

Cornstarch bioplastic vs Sugarcane bioplastic Infographic

materialdif.com

materialdif.com