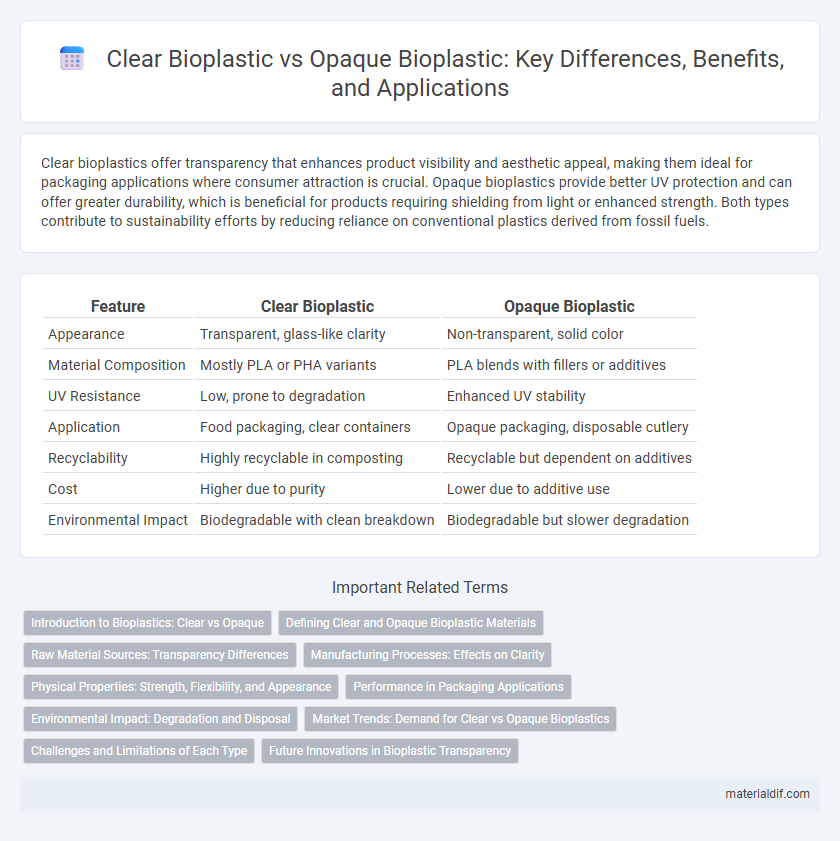

Clear bioplastics offer transparency that enhances product visibility and aesthetic appeal, making them ideal for packaging applications where consumer attraction is crucial. Opaque bioplastics provide better UV protection and can offer greater durability, which is beneficial for products requiring shielding from light or enhanced strength. Both types contribute to sustainability efforts by reducing reliance on conventional plastics derived from fossil fuels.

Table of Comparison

| Feature | Clear Bioplastic | Opaque Bioplastic |

|---|---|---|

| Appearance | Transparent, glass-like clarity | Non-transparent, solid color |

| Material Composition | Mostly PLA or PHA variants | PLA blends with fillers or additives |

| UV Resistance | Low, prone to degradation | Enhanced UV stability |

| Application | Food packaging, clear containers | Opaque packaging, disposable cutlery |

| Recyclability | Highly recyclable in composting | Recyclable but dependent on additives |

| Cost | Higher due to purity | Lower due to additive use |

| Environmental Impact | Biodegradable with clean breakdown | Biodegradable but slower degradation |

Introduction to Bioplastics: Clear vs Opaque

Clear bioplastics, often derived from polylactic acid (PLA), provide transparency and are ideal for packaging applications requiring product visibility, such as food containers and cosmetic packaging. Opaque bioplastics, typically made from starch blends or polyhydroxyalkanoates (PHA), offer enhanced UV protection and aesthetic options for products like disposable cutlery and plant pots. Both types contribute to reducing reliance on fossil fuels and minimizing environmental impact through biodegradability and renewable feedstocks.

Defining Clear and Opaque Bioplastic Materials

Clear bioplastic materials are typically composed of polymers like polylactic acid (PLA) or polyethylene terephthalate (PET) that allow light to pass through, offering transparency and visual appeal in packaging and consumer products. Opaque bioplastics, often made from starch blends, polyhydroxyalkanoates (PHA), or cellulose-based polymers, block light transmission and provide UV protection and enhanced durability. Both clear and opaque bioplastics serve distinct functional purposes, driven by their molecular structure and intended applications in sustainable product design.

Raw Material Sources: Transparency Differences

Clear bioplastics are primarily derived from raw materials like polylactic acid (PLA) sourced from corn starch or sugarcane, which naturally supports high transparency due to their molecular structure. In contrast, opaque bioplastics often involve additives or fillers such as cellulose fibers or mineral compounds, resulting in reduced light transmission and a matte finish. The inherent differences in raw material composition directly impact the optical properties and suitability for applications requiring either clarity or light diffusion.

Manufacturing Processes: Effects on Clarity

Clear bioplastics are typically produced through processes such as extrusion and injection molding using highly purified polymers and controlled cooling rates, which preserve polymer chain alignment and reduce crystallinity to enhance transparency. Opaque bioplastics result from faster cooling or the inclusion of additives, fillers, or reinforcements that cause light scattering by disrupting the uniform polymer matrix. Manufacturing parameters such as temperature, pressure, and cooling speed critically influence the molecular structure, directly impacting the optical clarity and final appearance of bioplastic products.

Physical Properties: Strength, Flexibility, and Appearance

Clear bioplastics typically exhibit high transparency and smooth surface finish, making them ideal for applications requiring visual appeal, but they may have lower strength and flexibility compared to opaque bioplastics. Opaque bioplastics often provide enhanced mechanical strength and increased flexibility due to the incorporation of additives or fillers that scatter light, resulting in a matte or solid appearance. The choice between clear and opaque bioplastics depends on the balance needed between aesthetic clarity and physical durability in specific product applications.

Performance in Packaging Applications

Clear bioplastic offers superior product visibility and consumer appeal, making it ideal for packaging applications where showcasing the contents is essential, such as food and cosmetics. Opaque bioplastic provides enhanced UV protection and better barrier properties against moisture and oxygen, extending shelf life in packaging for sensitive products. Both types deliver biodegradable advantages, but their performance depends on specific packaging requirements like transparency, durability, and protection.

Environmental Impact: Degradation and Disposal

Clear bioplastic generally degrades faster than opaque bioplastic due to its thinner molecular structure and higher exposure to sunlight, which accelerates photodegradation. Opaque bioplastics often contain additives or pigments that slow down biodegradation, potentially increasing environmental persistence and complicating composting processes. Proper disposal methods for both types are crucial, but clear bioplastics typically offer more eco-friendly end-of-life options such as industrial composting or biodegradation in marine environments.

Market Trends: Demand for Clear vs Opaque Bioplastics

Demand for clear bioplastics is rapidly increasing in packaging and consumer goods due to their high transparency and aesthetic appeal, catering to brands emphasizing product visibility and sustainability. Opaque bioplastics maintain steady growth in automotive, electronics, and construction sectors where durability and UV resistance are critical. Market trends indicate a growing preference for clear bioplastics in single-use applications, driven by consumer demand for eco-friendly alternatives with clear product display.

Challenges and Limitations of Each Type

Clear bioplastics often face challenges related to reduced UV resistance and potential brittleness, limiting their use in applications requiring durability and long-term exposure. Opaque bioplastics typically struggle with lower aesthetic appeal and transparency, which restricts their suitability for packaging that relies on product visibility. Both types experience limitations in mechanical strength and moisture barrier properties compared to conventional plastics, posing challenges for widespread adoption.

Future Innovations in Bioplastic Transparency

Clear bioplastic advancements focus on enhancing optical clarity through nanofillers and novel polymer blends, enabling improved biodegradability without compromising transparency. Opaque bioplastics integrate natural pigments and additives that maintain strength and UV protection while reducing environmental impact. Emerging innovations aim to tailor transparency levels to specific applications, supporting sustainability and functional performance in packaging and medical industries.

Clear bioplastic vs Opaque bioplastic Infographic

materialdif.com

materialdif.com