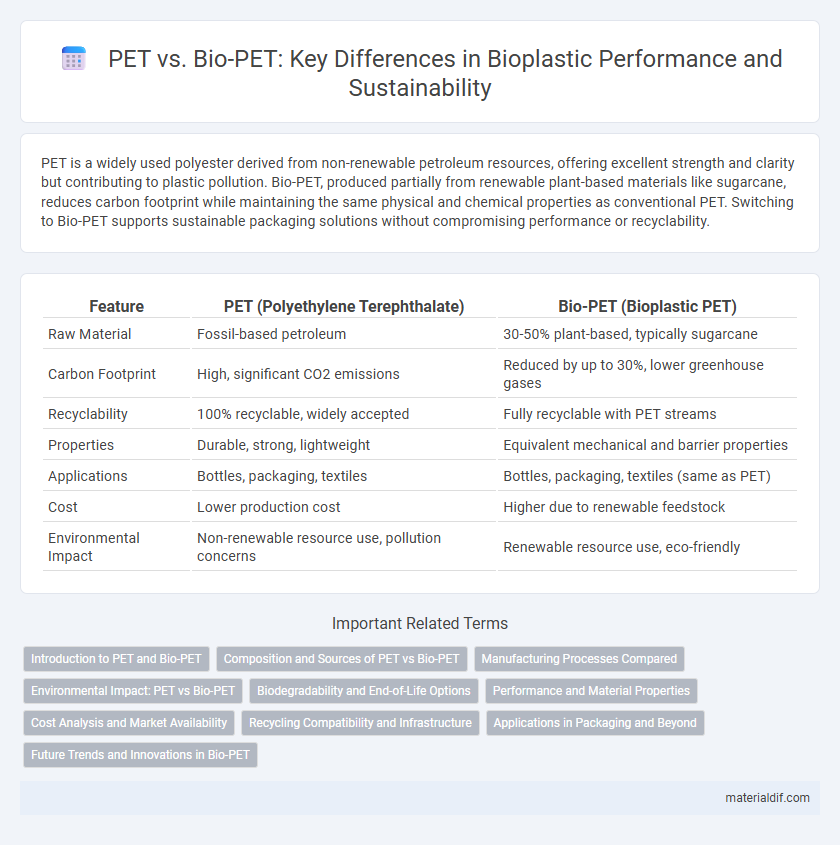

PET is a widely used polyester derived from non-renewable petroleum resources, offering excellent strength and clarity but contributing to plastic pollution. Bio-PET, produced partially from renewable plant-based materials like sugarcane, reduces carbon footprint while maintaining the same physical and chemical properties as conventional PET. Switching to Bio-PET supports sustainable packaging solutions without compromising performance or recyclability.

Table of Comparison

| Feature | PET (Polyethylene Terephthalate) | Bio-PET (Bioplastic PET) |

|---|---|---|

| Raw Material | Fossil-based petroleum | 30-50% plant-based, typically sugarcane |

| Carbon Footprint | High, significant CO2 emissions | Reduced by up to 30%, lower greenhouse gases |

| Recyclability | 100% recyclable, widely accepted | Fully recyclable with PET streams |

| Properties | Durable, strong, lightweight | Equivalent mechanical and barrier properties |

| Applications | Bottles, packaging, textiles | Bottles, packaging, textiles (same as PET) |

| Cost | Lower production cost | Higher due to renewable feedstock |

| Environmental Impact | Non-renewable resource use, pollution concerns | Renewable resource use, eco-friendly |

Introduction to PET and Bio-PET

Polyethylene terephthalate (PET) is a widely used synthetic polymer known for its strength, durability, and recyclability, primarily applied in packaging, especially beverage bottles. Bio-PET, derived partially from renewable biomass sources such as sugarcane, retains the chemical structure and performance properties of conventional PET while reducing fossil fuel dependence and carbon emissions. The integration of bio-based components in Bio-PET offers a sustainable alternative to traditional PET without compromising material functionality.

Composition and Sources of PET vs Bio-PET

PET (polyethylene terephthalate) is a petroleum-based plastic derived from fossil fuels, primarily ethylene glycol and terephthalic acid synthesized from crude oil. Bio-PET retains the same chemical structure as traditional PET but incorporates renewable plant-based materials, such as bioethanol from sugarcane, replacing ethylene glycol components to reduce fossil fuel dependency. The main difference in composition lies in the renewable origin of bio-PET's monomers, while both types maintain identical polymer properties and recyclability.

Manufacturing Processes Compared

PET is produced from petrochemical sources through the polymerization of ethylene glycol and terephthalic acid, involving energy-intensive refining and polymerization stages. Bio-PET utilizes bio-based ethylene glycol derived from renewable sources such as sugarcane, while maintaining the same polymerization process as conventional PET, resulting in a partially bio-based polymer. This shift in feedstock reduces reliance on fossil fuels and lowers the carbon footprint without altering the industrial manufacturing infrastructure.

Environmental Impact: PET vs Bio-PET

Bio-PET significantly reduces environmental impact by incorporating up to 30% plant-based materials derived from renewable resources like sugarcane, which decreases reliance on fossil fuels and lowers carbon emissions compared to traditional PET made entirely from petroleum. Life cycle analyses indicate Bio-PET offers substantial reductions in greenhouse gas emissions and energy consumption during production. However, both PET and Bio-PET require proper recycling systems to minimize plastic pollution and maximize sustainability benefits.

Biodegradability and End-of-Life Options

Bio-PET, derived partially from renewable biomass, shares the chemical structure of conventional PET, enabling similar recycling processes but offers improved sustainability through reduced fossil fuel dependency. Unlike traditional PET, which is not biodegradable and primarily relies on mechanical recycling or landfilling, Bio-PET's biodegradability depends on its composition and may degrade under industrial composting conditions but not in typical environmental settings. End-of-life management for Bio-PET emphasizes integration into existing PET recycling streams and potential advancements in chemical recycling technologies to enhance circularity and reduce environmental impact.

Performance and Material Properties

Bio-PET exhibits comparable mechanical strength, thermal stability, and barrier properties to traditional PET, ensuring its suitability for packaging and textile applications. Both materials offer excellent clarity and flexibility, with Bio-PET providing the added advantage of reduced carbon footprint due to its renewable feedstock. Performance metrics such as tensile strength and impact resistance remain consistent between PET and Bio-PET, supporting seamless integration into existing manufacturing processes.

Cost Analysis and Market Availability

Bio-PET generally incurs higher production costs compared to conventional PET due to the expensive bio-based feedstocks and emerging manufacturing technologies. Market availability of Bio-PET remains limited but is gradually expanding as major brands adopt sustainable packaging solutions, whereas PET dominates global markets with established supply chains and lower prices. Despite the cost premium, Bio-PET's growing demand is driven by increasing consumer preference for eco-friendly materials and regulatory incentives.

Recycling Compatibility and Infrastructure

PET is widely accepted in existing recycling infrastructure due to its standardized chemical composition and established collection systems, enabling efficient mechanical recycling processes. Bio-PET, chemically identical to conventional PET but derived partially from renewable resources, maintains full compatibility with current recycling streams and equipment without requiring significant infrastructure changes. The shared polymer structure of PET and Bio-PET ensures seamless integration into existing recycling facilities, supporting circular economy goals without compromising material recovery efficiency.

Applications in Packaging and Beyond

PET, a widely used plastic in packaging, offers durability and clarity ideal for bottles and containers, while Bio-PET, derived partially from renewable resources like sugarcane, maintains the same chemical properties and recyclability, making it a sustainable alternative. Bio-PET's applications extend beyond packaging to textiles and automotive parts, leveraging its eco-friendly profile without compromising performance. The shift towards Bio-PET supports reduced carbon footprints in industries requiring high-quality, recyclable materials.

Future Trends and Innovations in Bio-PET

Bio-PET is rapidly evolving with innovations targeting enhanced biodegradability and increased incorporation of renewable feedstocks, aiming to reduce environmental impact compared to traditional PET. Advanced catalytic processes and microbial fermentation are being developed to produce Bio-PET with higher purity and efficiency, enabling scalable production that meets global demand. Future trends emphasize circular economy integration through chemical recycling and bio-based monomer synthesis, positioning Bio-PET as a key material in sustainable packaging solutions.

PET vs Bio-PET Infographic

materialdif.com

materialdif.com