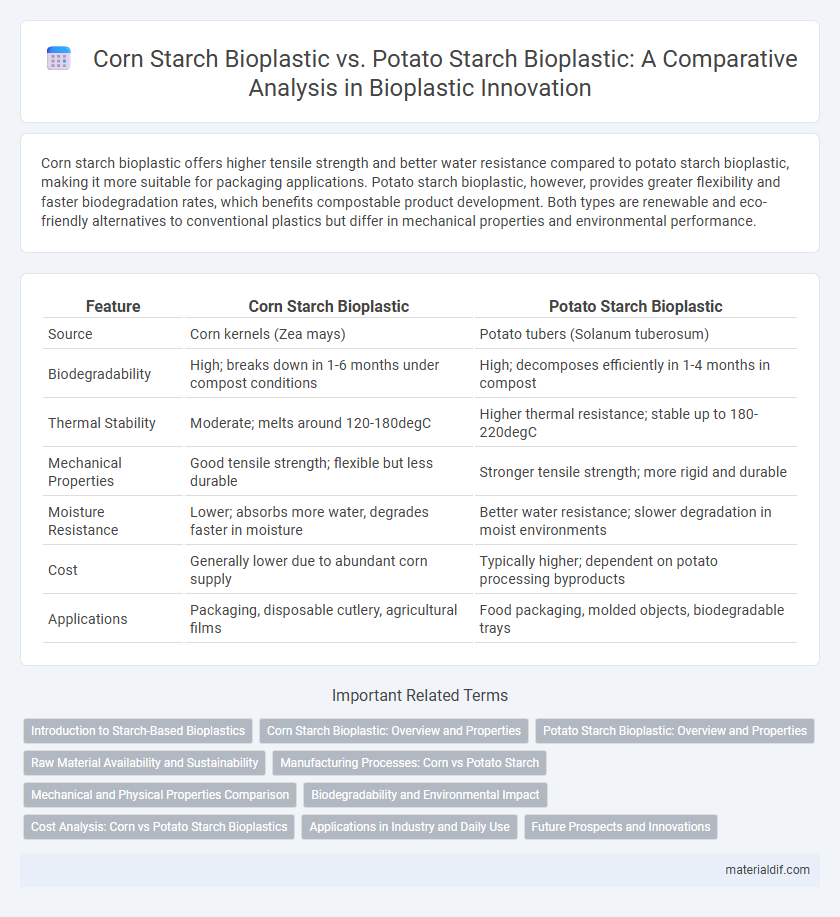

Corn starch bioplastic offers higher tensile strength and better water resistance compared to potato starch bioplastic, making it more suitable for packaging applications. Potato starch bioplastic, however, provides greater flexibility and faster biodegradation rates, which benefits compostable product development. Both types are renewable and eco-friendly alternatives to conventional plastics but differ in mechanical properties and environmental performance.

Table of Comparison

| Feature | Corn Starch Bioplastic | Potato Starch Bioplastic |

|---|---|---|

| Source | Corn kernels (Zea mays) | Potato tubers (Solanum tuberosum) |

| Biodegradability | High; breaks down in 1-6 months under compost conditions | High; decomposes efficiently in 1-4 months in compost |

| Thermal Stability | Moderate; melts around 120-180degC | Higher thermal resistance; stable up to 180-220degC |

| Mechanical Properties | Good tensile strength; flexible but less durable | Stronger tensile strength; more rigid and durable |

| Moisture Resistance | Lower; absorbs more water, degrades faster in moisture | Better water resistance; slower degradation in moist environments |

| Cost | Generally lower due to abundant corn supply | Typically higher; dependent on potato processing byproducts |

| Applications | Packaging, disposable cutlery, agricultural films | Food packaging, molded objects, biodegradable trays |

Introduction to Starch-Based Bioplastics

Starch-based bioplastics primarily utilize corn starch and potato starch due to their biodegradability and renewable nature, serving as sustainable alternatives to petroleum-based plastics. Corn starch bioplastics offer high tensile strength and faster processing times, while potato starch bioplastics provide superior flexibility and moisture resistance. Both types are integral in reducing environmental impact and advancing the bioplastics market through their unique molecular structures and functional properties.

Corn Starch Bioplastic: Overview and Properties

Corn starch bioplastic offers superior biodegradability and tensile strength compared to potato starch bioplastic, making it an eco-friendly alternative for packaging applications. Its high amylose content enhances film-forming ability and water resistance, resulting in durable and flexible bioplastics. Corn starch bioplastics also exhibit faster degradation rates in composting environments, supporting sustainable waste management practices.

Potato Starch Bioplastic: Overview and Properties

Potato starch bioplastic is derived from potato tubers and contains a high amylose content, which enhances its film-forming ability and mechanical strength. It exhibits excellent biodegradability and water resistance compared to corn starch bioplastic, making it suitable for packaging and agricultural applications. The thermal stability and flexibility of potato starch bioplastic also contribute to its growing popularity as an eco-friendly alternative to conventional plastics.

Raw Material Availability and Sustainability

Corn starch bioplastic benefits from widespread availability due to extensive corn cultivation, making it a cost-effective raw material, while potato starch bioplastic relies on potato crops that are less dominant globally but can be sourced sustainably in cooler climates. Both materials offer biodegradable properties, but potato starch bioplastic production generally requires less pesticide and fertilizer input, enhancing its sustainability profile. The choice between corn and potato starch bioplastics depends on regional crop production, environmental impact, and supply chain considerations.

Manufacturing Processes: Corn vs Potato Starch

Corn starch bioplastic manufacturing involves gelatinization through heating and mixing with plasticizers, followed by extrusion or casting processes to create flexible films. Potato starch bioplastic production requires higher temperatures and longer gelatinization times due to its larger granule size and higher amylose content, often resulting in stronger, more rigid biopolymers. Both processes rely on starch modification and plasticizer incorporation, but potato starch demands more energy-intensive processing to optimize its mechanical properties.

Mechanical and Physical Properties Comparison

Corn starch bioplastic exhibits higher tensile strength and better flexibility compared to potato starch bioplastic, making it more suitable for applications requiring durability. Potato starch bioplastic demonstrates greater water absorption and lower crystallinity, resulting in reduced mechanical stability under humid conditions. Both types show biodegradability, but corn starch bioplastic maintains structural integrity longer due to its superior physical properties.

Biodegradability and Environmental Impact

Corn starch bioplastic exhibits faster biodegradability in industrial composting conditions, breaking down within 90 to 120 days, whereas potato starch bioplastic may take slightly longer due to its denser molecular structure. Environmental impact assessments show that corn starch bioplastic typically results in lower greenhouse gas emissions during production because of its higher yield per hectare and more efficient processing methods. Both materials reduce dependency on fossil fuels, but corn starch bioplastic generally offers a more favorable profile in biodegradability and carbon footprint reduction.

Cost Analysis: Corn vs Potato Starch Bioplastics

Corn starch bioplastic generally offers a lower production cost compared to potato starch bioplastic due to the higher global availability and more established processing infrastructure for corn. Potato starch bioplastics might incur higher expenses linked to seasonal variability and less efficient extraction processes. Cost efficiency in corn starch bioplastics also benefits from economies of scale and more optimized supply chains.

Applications in Industry and Daily Use

Corn starch bioplastic is widely used in packaging, disposable cutlery, and agricultural films due to its excellent biodegradability and moisture resistance, making it ideal for food industry applications. Potato starch bioplastic offers superior flexibility and mechanical strength, which benefits industries requiring durable yet compostable materials such as automotive interiors and durable consumer goods. Both types serve sustainable alternatives in daily use, with corn starch bioplastics favored for single-use items and potato starch bioplastics preferred for products requiring enhanced durability.

Future Prospects and Innovations

Corn starch bioplastic offers a scalable and cost-effective platform for future innovations due to its abundant availability and well-established production processes. Potato starch bioplastic, with its higher amylose content, presents potential for enhanced mechanical properties and biodegradability, driving research towards improved material performance and broader application. Emerging advancements in enzymatic modification and nanocomposite incorporation are expected to accelerate the development of both bioplastics, positioning them as sustainable alternatives in the biodegradable polymer market.

Corn starch bioplastic vs Potato starch bioplastic Infographic

materialdif.com

materialdif.com