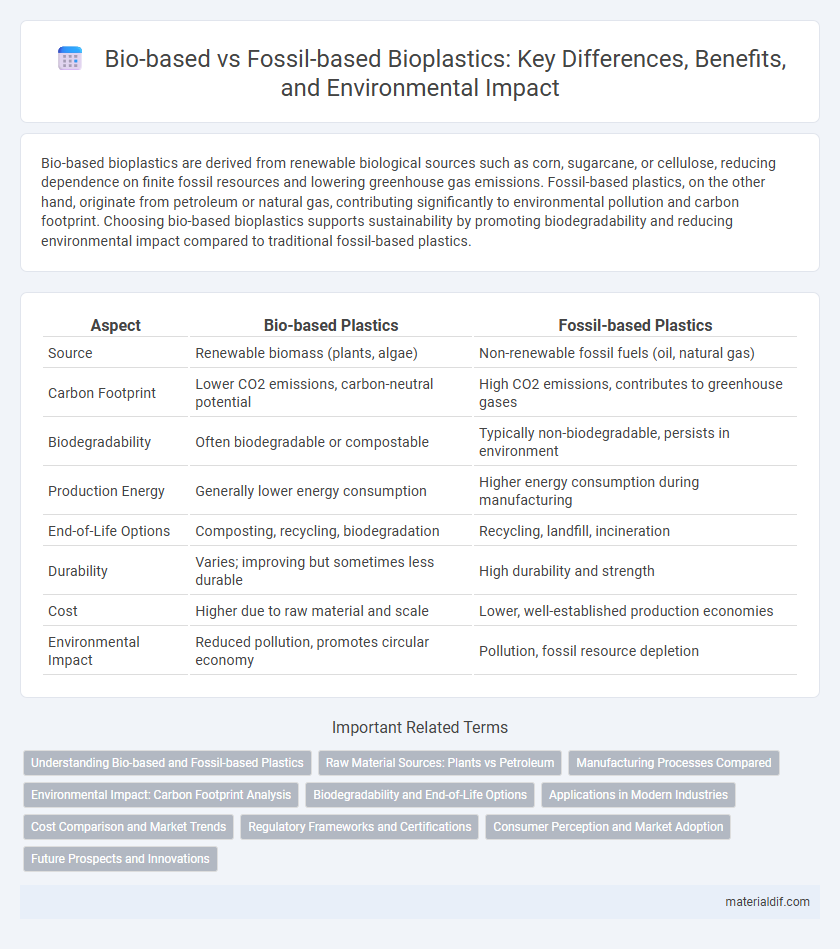

Bio-based bioplastics are derived from renewable biological sources such as corn, sugarcane, or cellulose, reducing dependence on finite fossil resources and lowering greenhouse gas emissions. Fossil-based plastics, on the other hand, originate from petroleum or natural gas, contributing significantly to environmental pollution and carbon footprint. Choosing bio-based bioplastics supports sustainability by promoting biodegradability and reducing environmental impact compared to traditional fossil-based plastics.

Table of Comparison

| Aspect | Bio-based Plastics | Fossil-based Plastics |

|---|---|---|

| Source | Renewable biomass (plants, algae) | Non-renewable fossil fuels (oil, natural gas) |

| Carbon Footprint | Lower CO2 emissions, carbon-neutral potential | High CO2 emissions, contributes to greenhouse gases |

| Biodegradability | Often biodegradable or compostable | Typically non-biodegradable, persists in environment |

| Production Energy | Generally lower energy consumption | Higher energy consumption during manufacturing |

| End-of-Life Options | Composting, recycling, biodegradation | Recycling, landfill, incineration |

| Durability | Varies; improving but sometimes less durable | High durability and strength |

| Cost | Higher due to raw material and scale | Lower, well-established production economies |

| Environmental Impact | Reduced pollution, promotes circular economy | Pollution, fossil resource depletion |

Understanding Bio-based and Fossil-based Plastics

Bio-based plastics are derived from renewable biological sources such as corn, sugarcane, and cellulose, reducing reliance on fossil fuels and lowering carbon footprints. Fossil-based plastics, made from petroleum or natural gas, dominate the market due to their cost-effectiveness and established production infrastructure. Understanding the chemical composition and lifecycle impacts of bio-based versus fossil-based plastics is critical for assessing sustainability and environmental benefits.

Raw Material Sources: Plants vs Petroleum

Bio-based bioplastics derive raw materials primarily from renewable plant sources such as corn, sugarcane, and cellulose, reducing dependence on finite petroleum reserves. Fossil-based plastics are produced from petrochemicals extracted from crude oil and natural gas, which are non-renewable and contribute to environmental degradation. Using plant-based raw materials supports carbon neutrality and promotes sustainability in plastic production.

Manufacturing Processes Compared

Bio-based bioplastics utilize renewable biomass such as corn, sugarcane, or cellulose in manufacturing, involving fermentation or polymerization techniques that convert these natural feedstocks into biopolymers like polylactic acid (PLA) or polyhydroxyalkanoates (PHA). Fossil-based plastics rely on petrochemical processes including cracking, refining, and polymerization of hydrocarbons derived from crude oil or natural gas, producing polymers such as polyethylene (PE) and polypropylene (PP). The bio-based process generally consumes less energy and results in lower greenhouse gas emissions compared to the fossil-based manufacturing that depends on finite resources and releases significant carbon dioxide during production.

Environmental Impact: Carbon Footprint Analysis

Bio-based bioplastics typically exhibit a lower carbon footprint compared to fossil-based plastics due to their renewable feedstocks and potential for carbon sequestration during biomass growth. Fossil-based plastics contribute significantly to greenhouse gas emissions through extraction, refining, and production processes, leading to higher environmental impacts. Lifecycle assessments indicate that transitioning to bio-based plastics can reduce overall carbon emissions and mitigate climate change effects.

Biodegradability and End-of-Life Options

Bio-based bioplastics are derived from renewable resources such as corn starch or sugarcane, offering enhanced biodegradability compared to fossil-based plastics made from petroleum. Biodegradability in bio-based plastics enables microbial decomposition under specific conditions, reducing environmental impact and landfill volume. End-of-life options for bio-based bioplastics include composting and anaerobic digestion, whereas fossil-based plastics primarily rely on recycling or incineration, often resulting in long-term ecological persistence.

Applications in Modern Industries

Bio-based bioplastics are increasingly utilized in packaging, automotive components, and consumer electronics due to their renewable origin and reduced carbon footprint compared to fossil-based plastics. Modern industries leverage bio-based materials for their biodegradability and compatibility with sustainable manufacturing processes, enhancing circular economy initiatives. Fossil-based plastics remain prevalent in heavy-duty applications requiring high durability and temperature resistance, but the shift towards bio-based alternatives is accelerating innovation across sectors.

Cost Comparison and Market Trends

Bio-based bioplastics currently exhibit higher production costs compared to fossil-based plastics due to limited economies of scale and raw material prices. Market trends indicate increasing consumer demand and regulatory support, driving investment and cost reductions in bio-based alternatives. Continued innovation and scaling are expected to narrow the price gap, enhancing the competitiveness of bio-based bioplastics in global markets.

Regulatory Frameworks and Certifications

Bio-based bioplastics are increasingly supported by regulatory frameworks that incentivize renewable materials, such as the European Union's Green Deal and the U.S. Food and Drug Administration's guidelines for biopolymer safety. Fossil-based plastics face stricter regulations due to their environmental impact, including carbon taxes and bans on single-use plastics by governments worldwide. Certifications like the USDA BioPreferred Program and TUV Austria's OK compost ensure bio-based bioplastics meet sustainability and biodegradability standards, differentiating them from conventional fossil-based counterparts.

Consumer Perception and Market Adoption

Consumer perception of bio-based bioplastics often emphasizes environmental benefits and sustainability, driving higher market adoption compared to fossil-based plastics. Surveys indicate that eco-conscious consumers prefer bio-based options despite potentially higher costs, influencing retailers and manufacturers to increase their use. Market trends show accelerating growth in bio-based bioplastics, particularly in packaging and single-use items, fueled by regulatory support and shifting consumer demand away from traditional fossil-based plastics.

Future Prospects and Innovations

Bio-based bioplastics derive from renewable resources such as corn, sugarcane, and cellulose, offering a sustainable alternative to fossil-based plastics that rely on petroleum and natural gas. Innovations in bio-catalysts, enzyme engineering, and microbial fermentation are rapidly improving the efficiency and cost-effectiveness of producing bio-based polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA). Future prospects include developing fully biodegradable composites, enhancing carbon capture during production, and integrating bio-based plastics into circular economy frameworks to reduce environmental impact and dependence on fossil fuels.

Bio-based vs Fossil-based Infographic

materialdif.com

materialdif.com